40

SALICRU

6.7. OPERATING INSTRUCTIONS FOR MAINTENANCE OF

POWER MODULES.

These actions are reserved exclusively for the

T.S.S.

personnel

or the distributor.

6.7.1. Maintenance guide for power modules.

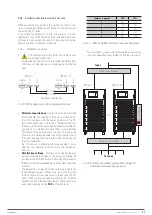

6.7.1.1. With the system operating in Normal Mode and the

normal bypass voltage and frequency, with at least 1

power module as redundant:

1.

Click on the icon

in the "Operation" menu to enable

the power module shutdown function.

2.

Using the "On/Off” button next to the LED indications on

the front panel, manually stop the power module. Use an

object of diameter ≤ 3 mm, such as a small screwdriver,

to insert it into the hole indicated as “ ” and press for

around 5-6 seconds on the button located inside.

3.

Remove the fixing screws of the side trim profiles and the

power module fixing screws.

Slightly pull the handle on each end of the module and re-

move it 4-5 cm from the socket to remove it from the con-

nector on the backplane of the device.

Wait around 10 minutes and remove it from its slot.

To ensure safety, check with an instrument the

voltage of the DC bus, which should be below 60 V

DC.

6.7.1.2. No power modules operating as redundant:

1.

Click on the icon

in the "Operation" menu to switch

to "Bypass Mode".

2.

Click on the icon

in the "Operation" menu to enable

the power module shutdown function.

3.

Manually stop the power module by pressing the button “

” for around 5-6 sec.

4.

Remove the fixing screws of the side trim profiles and the

power module fixing screws.

Slightly pull the handle on each end of the module and re-

move it 4-5 cm from the socket to remove it from the con-

nector on the backplane of the device.

Wait around 10 minutes and remove it from its slot.

To ensure safety, check with an instrument the

voltage of the DC bus, which should be below 60 V

DC.

5.

After the end of the maintenance operations, insert the

power module until it is at the end of its slot to connect

to the "backplane" of the equipment. After around 2 min

the power module will activate automatically adding to the

parallel of the rest of the modules.

6.

Insert and tighten the fixing screws of the module.

7.

Fit the side profiles, their screws, and fix them in place.

6.8. OPERATING INSTRUCTIONS FOR MAINTENANCE OF

THE BYPASS AND MONITORING MODULE.

The bypass and monitoring module cannot be operated

in Battery Mode.

These actions are reserved exclusively for the

T.S.S.

staff or

the distributor.

6.8.1.1. With the system operating in Normal Mode and normal

bypass voltage and frequency, transfer the load over the

manual bypass.

1.

Manually stop the inverter. The UPS will transfer to Bypass

Mode.

2.

Remove the mechanical lock of the manual bypass switch

from the external panel and turn it to "On". The load will be

fed directly from the mains via the manual bypass.

When a protection panel is provided instead of a manual

bypass panel, the mechanical lock of the bypass switch

from the back of the sub-rack must be removed manually

and turn it to "On" as this switch will not be available in

the panel.

3.

Turn the protection or the battery circuit breaker of the bat-

tery cabinet to "Off" position.

4.

Turn the circuit breakers of the manual bypass panel to the

“Off” position in the following order: Output, Input and By-

pass [equipment version B, with separate bypass line].

5.

Remove the fixing screws of the side trim profiles and the

MBS fixing screws.

Slightly pull the handle on each end of the module and re-

move it 4-5 cm from the socket to remove it from the con-

nector on the backplane of the device.

Wait around 10 minutes and remove it from its slot.

Carry out the appropriate maintenance.

6.

After the end of the maintenance operations, insert the by-

pass and monitoring module until it is at the end of its slot

to connect to the "backplane" of the equipment.

All UPS configuration parameters are stored in the

bypass and monitoring module. Any replacement

entails the necessary programming of the same parameters

as the original module. This task is reserved exclusively for

T.S.S.

personnel or distributors.

Replacing one bypass module with another one without

carrying out the corresponding configuration can lead to

serious or very serious faults.

7.

Insert and tighten the fixing screws of the module.

8.

Fit the side profiles, their screws, and fix them in place.

9.

Proceed as described in section 6.4.2. to switch back to

Normal Mode.

The force that has to be made to connect the MBS to the

backplane of the equipment is higher than for the MPs,

since the terminals of the connector are of a greater section.

6.9. LANGUAGE SELECTION.

The menus displayed on the LCD touch screen and the display

of parameters and data are available in 3 languages:

•

Spanish.

•

English.

•

Portuguese.

To select a language, perform the following:

1.

Click on the icon

within the main menu to enter the

setup menu on the LCD.

2.

Select the “Language” menu.

3.

Select the required language. From this moment all the

menus, parameters and data will be displayed in the se-

lected language.