28

SALICRU

5.4.3. Access to the interior of the subrack for its

connection.

•

All subrack units in the SLC ADAPT X series have the fol-

lowing connection elements:

Terminal block for power. Depending on the type of the

input and output, some terminal strips are supplied be-

tween terminals to obtain the required configuration

(see Fig. 6, 7 and 8).

Separate terminal block connectors for digital inputs

and dry contacts signals.

Terminal block connector for RS485.

DB9 connector for RS232.

Slot ready to integrate the SNMP card.

The 6-slot subracks also have HDB15 / DB15 connec-

tors for the parallel bus.

•

All power connection terminals (input, output and batteries)

are located on the back of the subracks, behind a protective

cover. Only

T.S.S.

personnel or

qualified

personnel are au-

thorized to remove these covers for connection.

Do not remove more covers than indicated. Access to other

internal parts is reserved exclusively for

T.S.S.

•

The dry contacts connectors are arranged in:

2-slot and 4-slot subracks. On the front of the UPS, be-

hind the metal cover located next to the control panel.

6-slot subracks. On the back of the UPS, behind a metal

protective cover.

•

Consider the cross section of the cables and crimped termi-

nals at their ends, in relation to the surface and size of the

terminals, to obtain optimum contact between them.

•

At the end of the wiring tasks, the equipment must be

fitted with the corresponding covers firmly attached. This

includes the right lateral frontal profile, used as a channel

for the passage of the interface cables and related at the

point ‘

j.

’ of section 5.2.3.

5.5. CONNECTION.

•

The connection of the equipment can only be carried

out by

qualified

personnel with the help of the sup-

plied documentation, however the first commissioning of

the system is reserved exclusively to our

T.S.S.

or distrib-

utor, as an implicit action that activates the start of the

guarantee of the product .

Do not apply power to the equipment before the first com-

missioning.

•

This equipment is suitable for installation in networks with

power distribution system TT, TN-S, TN-C or IT, taking into

account at the time of installation the particularities of the

system used and the national electrical regulation of the

destination country.

•

In equipment with three-phase input will feed the

system with 4 wires (3 phases and Neutral), being

essential the neutral in the power of all three-phase

system.

Optionally we can supply an isolation transformer to gen-

erate the neutral, in those mains supply that do not have it.

Only in single-phase equipments and in compliance with

the nominal supply voltage of the equipment, it is possible

to dispense with the neutral and to replace it with another

phase in its absence. In this case and in equipment with

independent bypass line, as in any equipment, respect the

rotation of the phases when connecting the input and by-

pass, using the same pair of phases in both inputs.

•

In equipments with three-phase input connected to an IT-

type power distribution system, breakers, differentials and

circuit breaker protections must cut the NEUTRAL in addi-

tion to the three phases.

•

All the connections of the equipment including the control

ones will be done with all the switches at rest position

and with no power supply (power supply line switch of the

equipment in «Off» position).

•

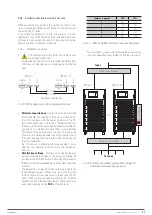

Do not connect ADAPT X devices in parallel with different

firmware versions, settings and/or back-up times. Follow

all instructions for connecting up to 5 subracks in parallel

(6-slot subracks only).

•

The tightening torques of the screw terminals are as fol-

lows:

For screw with M6 thread, tightening torque of 5Nm.

For screw with M8 thread, tightening torque of 13Nm.

For screw with M10 thread, tightening torque of 25Nm.

•

The parallel connection of 6-slot subracks will be carried

out as described in sections 5.5.1 to 5.5.5 and for each one

of them, and is subject to having its manual bypass panel

for both the installation procedure, start-up and future

maintenance.

5.5.1. Connecting the device to the mains.

•

As it is an equipment with protection against class I

electrical shock, it is essential to install the protec-

tive earth conductor to the terminal identified as

. Con-

nect this conductor before supplying voltage to the input

terminals.

•

In accordance with the safety standard EN-IEC 62040-1,

in equipments without independent bypass line, the in-

stallation must be equipped with an automatic backfeed

protection system, such as a contactor, which prevents the

occurrence voltage or hazardous energy on the UPS input

line during a mains failure.

The standard is applicable regardless of whether the power

supply is single-phase or three-phase, and for individual

units of subracks as well as for each of the UPS subracks of

a parallel system.

All values are calculated for a

maximum total cable

length of 30 m

between the distribution board, equipment

and loads.

•

There can be no derivation of the line from the Back-

feed protection to the UPS, since the safety standard

will not be complied with.

•

Warning labels shall be affixed to all primary power

switches installed in areas remote from the equipment to

alert electrical maintenance personnel of the presence of a

UPS in the circuit.