22

SALICRU

Do not leave the equipment at ground level as it is

usually the area with the highest solid elements in

suspension and through the permanent forced

cooling itself penetrate inside causing short or long

term breakdowns of all kinds.

For obvious reasons, this location is more prone to

risk factors such as falling of liquids on the equip-

ment, unintentional impacts, obstruction of the

ventilation grids by materials placed in front of the

equipment, ..., which can lead to serious or very se-

rious damages. And also leaves the control panel in

a plane or inconspicuous position.

•

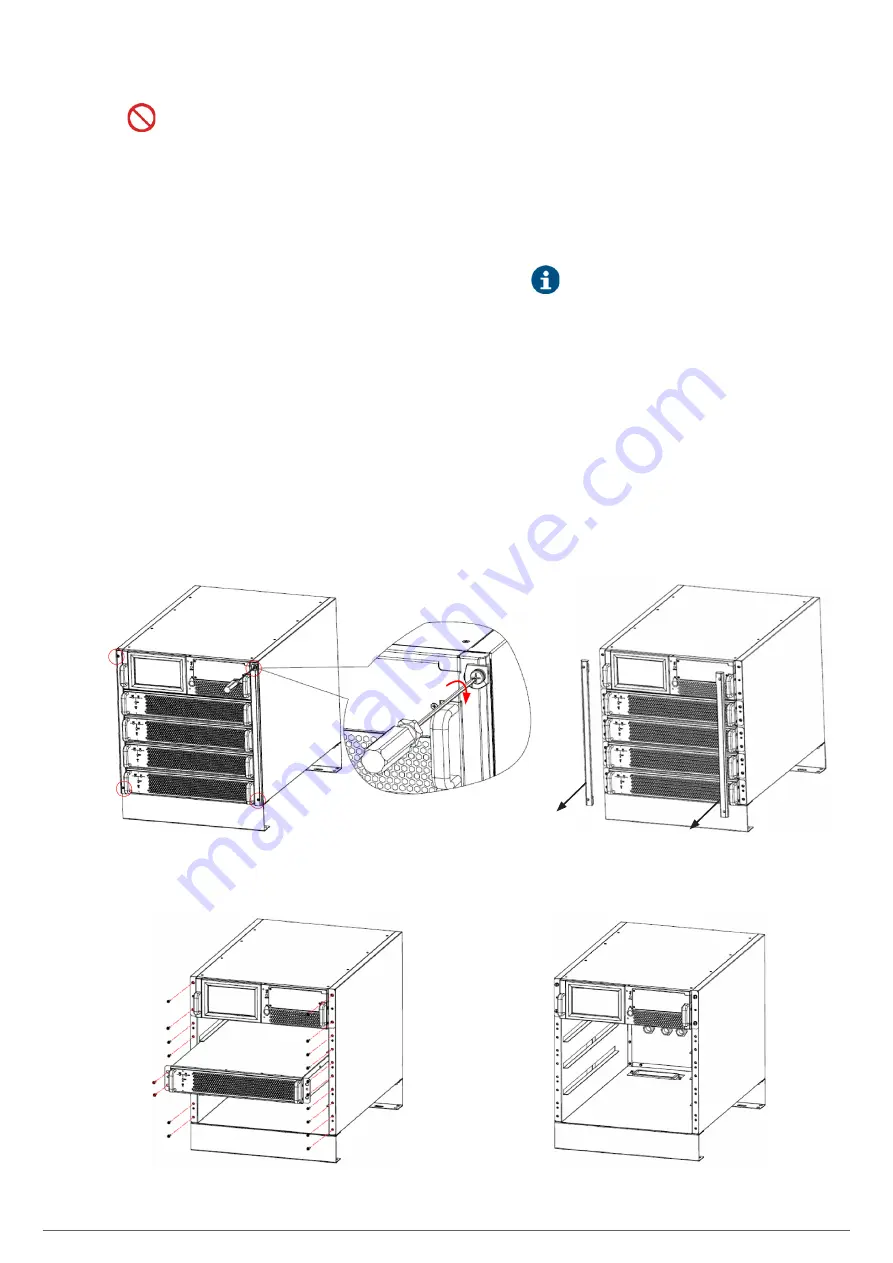

With regard to the subrack of 6 slots, although it can be

integrated in a rack type cabinet, the structure itself is de-

signed to operate as an equipment. This subrack has cas-

tors with mechanical lock for immobilization.

•

In subrack equipment intended for installation inside a rack

cabinet, the following actions will be performed according

to the model for adaptation. Consider that the illustrations

in Fig. 22, although they belong to the subracks of 4 slots

except some punctual for those of 6 slots, are taken as rep-

resentative of the whole range:

a.

Remove the two fixing screws from one of the side trim

and the trim itself.

b.

Operate as in point

a.

with the other trim.

c.

Remove all the fixing screws of the modules leaving

the fixing of the bypass module with the control panel.

d.

Using the two handles located on the sides, pull the

module on the top of the subrack until it is unplugged

from the connector on the backplane. Do not remove it

completely.

When the module is half-drawn, take it under-

neath instead of the handle and proceed to its

complete withdrawal from the subrack.

The removal of modules will always be initiated by the

one located at the top of the subrack, in order to keep

the center of gravity as low as possible.

a - b

c - d - e