511026 Rev. 07-01-19

35

3.20 Labeling Tape Cartridges

Barcode labels are recommended in production environments to improve inventory time in the library and

ease cartridge handling processes outside the library.

The Q40 contains a bar code reader that reads the tape labels and stores the inventory data in memory.

The Q40 then provides the inventory information to the host application, OCP, and RMI. Having a bar

code label on each tape cartridge enables the bar code reader to identify the cartridge quickly, thereby

speeding up inventory time. Make it a practice to use bar code labels on your tape cartridges.

A proper bar code label includes the media identifier in the last two characters of the bar code. The library

will not load an incompatible cartridge, based on the barcode media identifier, into a tape drive. For

example, the library will not load a cartridge labeled as L3 into an LTO-6 tape drive.

Your host software may need to keep track of the following information via the associated bar code:

•

Date of format or initialization

•

Tape's media pool

•

Data residing on the tape

•

Age of the backup

•

Errors encountered while using the tape (to determine if the tape is faulty)

!

IMPORTANT

Misusing and misunderstanding barcode technology can result in

backup and restore failures. Use only high-quality labels. Self-printed

labels are not recommended as they are often a source of barcode

reading issues.

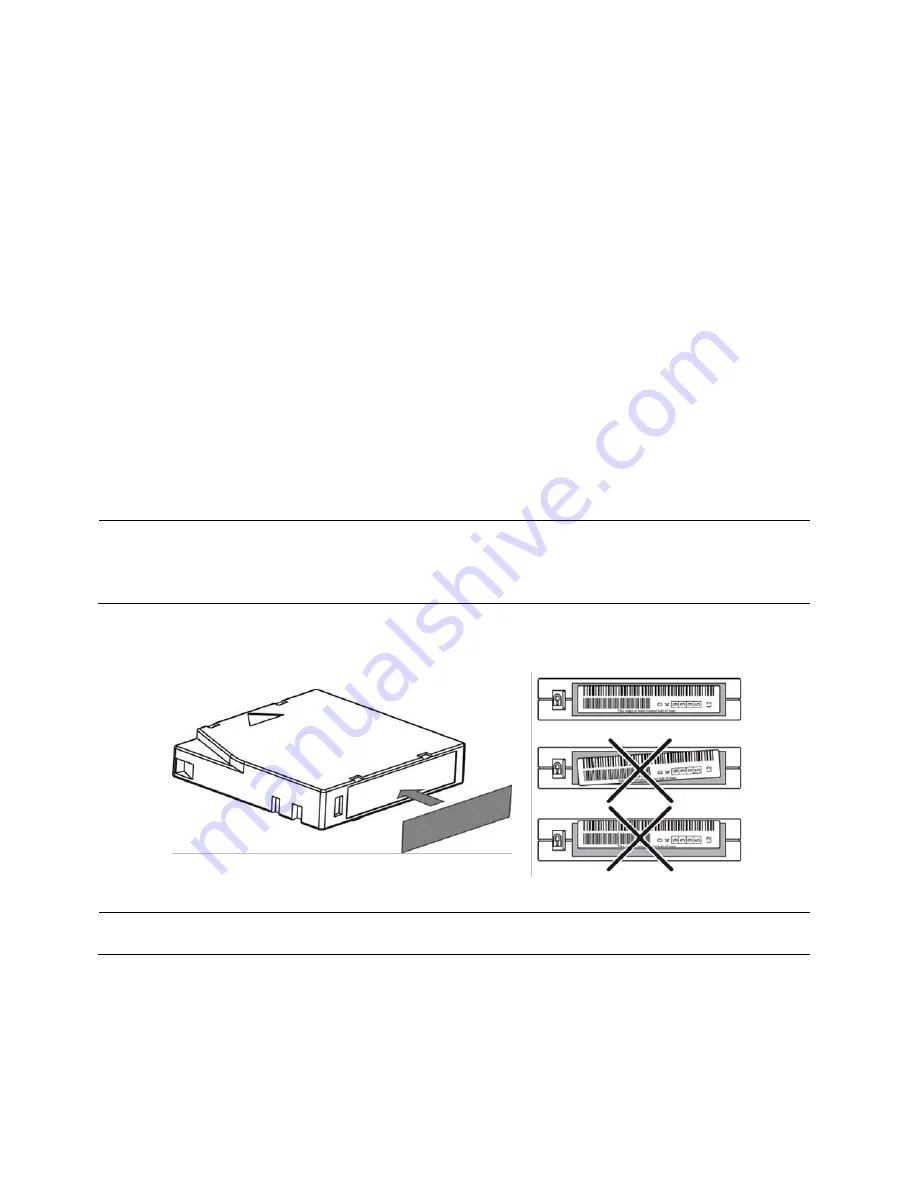

LTO tape cartridges have a recessed area located on the face of the cartridge next to the write-protect

switch. Use this area for attaching the adhesive-backed bar code label. Only apply labels as shown:

!

IMPORTANT

Never apply multiple labels onto a cartridge because extra labels can

cause the cartridge to jam in a tape drive.