Parker Hannifin Corporation

Parflex Division

Ravenna, Ohio

Bulletin No. 4660-PGP2T

Parflex

®

Flexible Gas Piping System

Design and Installation Guide

2.1 Parflex System Description

The Parflex Flexible Gas Piping System, Parflex System, has a number of essential hardware and design differences

from conventional gas piping systems using rigid steel (Schedule 40) pipe. These differences can be described as

follows:

a) The system uses CSST made of 300 series type material.

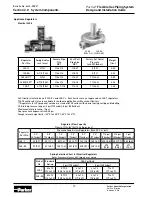

b) The CSST is connected using special patented FastMate™ quick connect mechanical fittings designed specifi-

cally for Parker Parflex CSST.

c) In many applications, the CSST is sized for individual gas appliance loads and is, therefore, usually small in

diameter. CSST can be piped in parallel from a distribution manifold and in series like common steel pipe sys-

tems.

d) The small diameter CSST is suitable for use with elevated pressure systems (above 1/2 psi up to 5 psi).

e) Different practices are required in the handling and installation of semi-rigid tubing compared to steel pipe.

The Parflex System may be Applied in combination with schedule 40 steel pipe using approved threaded couplings

at the interface.

CSST can be used for both the low-pressure system (below 1/2 psi) and elevated-pressure system

design. It is approved for propane and natural gas applications.

The final Application depends on local plumbing restrictions and codes, floor plan, appliance locations, availability

of elevated street pressure and total gas load. This design manual does not dictate the type of the gas distribution

system configuration. The configuration is left up to the system designer. This manual will aid in sizing tubing for the

system once the configuration has been selected. The installer should contact the local gas distributor to confirm

available service pressures.

Section 2.0 System Components