Parker Hannifin Corporation

Parflex Division

Ravenna, Ohio

Bulletin No. 4660-PGP2T

1

Parflex

®

Flexible Gas Piping System

Design and Installation Guide

3.1.2

Pressure System

Low Pressure System

— Low pressure sys-

tems have gas service pressure down-

stream of the meter at less than 1/2 psi

(14 inches WC). These systems typically

have 7 inches WC (1/4 psi) system pres-

sure for natural gas and 11 inches WC

for propane. The allowable pressure drop

along any piping run may be specified by

local codes. The minimum pressure sup-

plied to each appliance should be con-

sidered. Typically, natural gas appliances

require 4 inches WC, and propane (LPG)

appliances require 10" WC minimum sup-

ply pressure measured at the appliance.

The second stage regulator for propane

systems is often set at 11 inches WC and

a 1/2 inch WC maximum pressure drop is

allowed through each line. A low-pressure

series arrangement typically requires

larger diameter tubing to meet appliance

demands.

S

ection 3.0 System Configuration & Sizing

Parallel System

— Parallel system layouts

utilize a central distribution manifold

from which appliances are supplied

by branch runs. The manifold is often

located closest to the appliance with

the highest load; typically, the furnace

or boiler. A parallel layout is commonly

used in elevated supply pressure

systems (above 7 inches WC, 1/4 psi).

Generally, a parallel layout requires a

higher total footage of smaller diame-

ter tubing and fewer fittings compared

with a series layout.

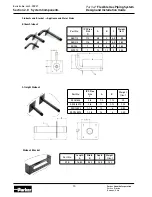

Parallel System Layout

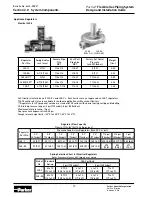

Low Pressure Natural Gas or Propane System (Series)