Parker Hannifin Corporation

Parflex Division

Ravenna, Ohio

Bulletin No. 4660-PGP2T

Parflex

®

Flexible Gas Piping System

Design and Installation Guide

3.2.6

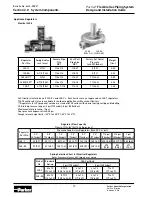

Parflex System / Steel Pipe Hybrid System Example

Hybrid System

— Hybrid system layouts use

a combination of CSST and rigid pipe on low

or medium pressure systems. These systems

typically have long runs and high loads. The

rigid pipe is used on long straight runs and

the CSST is used to connect to the units.

In this example, we are supplied with 7 inches

WC and the gas company has stated the spe-

cific gravity of the natural gas is 0.60. Local

codes require a pressure drop of 0.5 in. WC.

Hybrid System Example 1

This is a low-pressure series system with four

natural gas appliances. The main trunk line in

this system is specified as black iron and the

branches are determined to be Parflex tubing.

The utility company supply pressure exit-

ing the meter is 7 inches water column. The

maximum allowable pressure drop across the

longest length from the meter to the farthest

appliance is 1/2 inch water column. Because

we are using both black iron pipe and the

Parflex tubing, we need to two types of pres-

sure tables. We will use Steel Tables (Table

17, Section 7.1) and Parflex Table of 0.5 psig or

less with a pressure drop of 0.5 in. WC (Table

1, Section 7.1).

1. Determine the total gas load for each

appliance in cubic feet per hour:

Furnace ............................. 75 CFH (75,000 BTUH/1000 BTUH per CFH)

Oven/range ....................... 50 CFH (50,000 BTUH/1000 BTUH per CFH)

Dryer ................................. 25 CFH (25,000 BTUH/1000 BTUH per CFH)

Water heater ..................... 34 CFH (34,000 BTUH/1000 BTUH per CFH)

Total .................................. 184 CFH

2. Measure the length of each run and determine the maximum length from the meter to the farthest

appliance.

A = 20 ft., B = 30 ft., C = 10 ft., D = 18 ft., E = 10 ft., F = 15 ft. G = 12 ft.

Furnace = A + E = 20 ft. + 10 ft. = 30 ft

Oven/range = A + B + F = 20 ft. + 30 ft. + 15 ft. = 65 ft.

Dryer = A + B + C + G = 20 ft. + 30 ft. + 10 ft. + 12 ft. = 72 ft.

Water heater = A + B + C + D = 20 ft. + 30 ft. + 10 ft. + 18 ft. = 78 ft.

The longest run is from the meter to the water heater over 78 ft.

3) Sizing Section A – Length A must be sized to handle the total load of all appliances and the total

pressure drop from the meter to the farthest appliance. The total appliance load is 184 CFH. Using the

longest length sizing method, the length is 78 ft. to the water heater. Referring to Table 17 (7 inches

WC inlet pressure and 1/2 inch WC pressure drop) under the 80 ft. length column (next longest length

column), we find that 1 inch size black iron pipe has a flow capacity exceeding 184 CFH (220 CFH). Use

1 inch black iron pipe to run Section A.

4. Sizing Section B – Section B must supply the water heater, dryer, and range. The total pressure drop

for the system is considered to be from the meter to the water heater (farthest appliance). The total

appliance load is 34 + 25 + 50 = 109 CFH. Using the longest length sizing method, the length is 78 ft.

(distance from meter to water heater). Referring to Table 17 under the 80 ft. length column, we find

that size 3/4 inch black iron pipe has flow capacity over 109 CFH (118). Use 3/4 inch black iron pipe to

run Section B.

Section 3.0 System Configuration & Sizing

Hybrid System

Appliance Loads

Lengths

Tube Size

-

A = 20 ft.

1" Black Iron

-

B = 30 ft.

3/4" Black Iron

-

C = 10 ft.

3/4" Black Iron

Oven/Range = 50 CFH

D = 18 ft.

PGP-8 (1/2")

Furnace = 75 CFH

E = 10 ft.

PGP-12 (3/4")

Dryer = 25 CFH

F = 15 ft.

PGP-16 (1")

Water heater = 34 CFH

G = 12 ft.

PGP-8 (1/2")

Total 184 CFH