Parker Hannifin Corporation

Parflex Division

Ravenna, Ohio

Bulletin No. 4660-PGP2T

1

Parflex

®

Flexible Gas Piping System

Design and Installation Guide

3.1 System Configuration

The final piping system design depends on local plumbing restrictions and codes, floor plan, appliance locations,

availability of elevated street pressure, total gas load, and system cost. This design manual does not dictate the type

of the gas distribution system configuration. The configuration is left up to the system designer. This manual will aid

in sizing tubing for the system once the configuration has been selected.

3.1.1

System Planning

Prior to the piping installation, carefully follow the steps provided below

1. Confirm that the local building code authority has accepted the use of the Parflex System. Contact your

Parflex System distributor for this information.

2. Check with the local gas utility or supplier to determine the metered gas supply pressure.

Natural Gas —

Supply pressure in the USA and Canada is typically 6 to 7 inches water column (1/4 psi

or 4 ounces). Higher supply pressures 1/2 psi (14 inches WC), 1 psi (28 inches WC), and 2 psi (56 inches

WC) will allow reduced tubing size in the Parflex System design plan. The Parflex System can also be

used in 5 psi supply pressure systems which are normally restricted to commercial installations.

Propane

(LPG–Liquid Petroleum Gas) — Typical propane supply pressure for residential buildings is 11

inches water column set at the second stage regulator outside the building. Higher supply pressures

will allow reduced tubing size. Check with your propane supplier and local building code authority.

3. Prepare a dimensioned sketch of the installation showing the location of each appliance and possible

piping routes.

4. Determine the load (BTU/hr or CFH) demand and the minimum required inlet pressure for each ap-

pliance. This data is commonly found on the manufacturer’s nameplate on each gas appliance or is

provided by the builder/contractor.

5. Determine the total capacity for all appliances planned in the installation. The BTU equivalents for

natural gas or propane flow (CFH) can be obtained from the local gas utility or propane supplier. For

natural gas, one cubic foot per hour (1 CFH) is approximately 1,000 BTUH. For propane, one cubic foot

per hour (1 CFH) is approximately 2,500 BTUH. The capacity tables in this guide can be used for sizing

to meet appliance BTU input loads.

6. Determine the type of piping layout which best fits the installation.

Section 3.0 System Configuration & Sizing

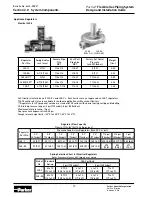

Sizing and Pressure Loss

—

The design of a gas system under maximum probable flow conditions must

provide gas volume and pressure from the meter to the appliance must be delivered greater than the

minimum volume and pressure required for proper equipment operation.

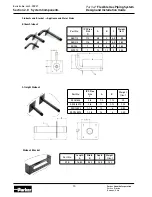

Series System

— Series system layouts are

common in low-pressure, rigid steel

piping systems. Numerous elbow and

tee fittings are used to branch off of

a main run. Generally, a series layout

requires larger tubing sizes and more

fittings compared with a parallel lay-

out.

Series System Layout