Parker Hannifin Corporation

Parflex Division

Ravenna, Ohio

Bulletin No. 4660-PGP2T

Parflex

®

Flexible Gas Piping System

Design and Installation Guide

Section 3.0 System Configuration & Sizing

3.2.5

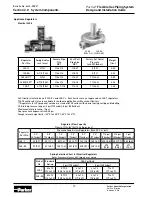

Parallel Elevated System Example

Elevated Parallel

This example shows a rooftop application to six

HVAC Units. Each unit requires 225,000 BTUH

Natural Gas.

In this example, we are supplied with 5 psig and

the gas company has stated the specific gravity

of the natural gas is 0.60. Local codes require a

pressure drop of 3.5 psig.

The HVAC Units have been spaced so they are

equal in distance.

1. Determine the total gas load for each appli-

ance in cubic feet per hour:

2. Measure the length of each run and deter-

mine the maximum length from the meter to

the farthest appliance.

A = 75 ft., B = 25 ft., C = 25 ft., D = 25 ft., E = 25

ft., F = 25 ft. G = 25ft. H = 25ft. I = 25ft.

Farthest Unit = A + B + C + H = 75 ft. + 25 ft. +

25 ft. + 25 ft. = 150 ft.

The longest run is from the meter to the last

HVAC Unit at 150 ft.

3. Sizing Section A – Length A must be sized to

handle the total load of all appliances and

the total pressure drop from the meter to the

farthest appliance. The total appliance load

is 1,350 CFH. Using the longest length sizing

method, the length is 150 ft. to the last HVAC

Unit. Referring to Table 11 (5.0 psig; Pressure

Drop: 3.5 psig) under the 150 ft. length column,

we find that 1 inch Parflex tubing (PGP-16) has a flow capacity exceeding 1,350 CFH (1,539 CFH). Use 1

inch Parflex tubing (PGP-16) to run Section A.

4. Sizing Section B – Section B must supply four HVAC Units. The total pressure drop for the system is

considered to be from the meter to the last HVAC Unit. The total appliance load is 225 + 225 + 225 + 225

= 900 CFH. Using the longest length sizing method, the length is 150 ft. Referring to Table 11 under the

150 ft. length column, we find that size 1 inch Parflex tubing (PGP-16) has flow capacity over 900 CFH

(1,539 CFH). Use 1 inch Parflex tubing (PGP-16) to run Section B.

5. Sizing Section C – Section C must supply the final two HVAC Units. The total appliance load is 225 + 225

= 450 CFH. Using the longest length method, the length is 150 ft. Referring to Table 11 under the 150 ft.

length column, we find that 3/4 tubing (PGP-12) has flow capacity above 450 CFH (570). Use 3/4 Parflex

tubing (PGP-12) to run Section C.

6. Sizing Section D – Section D supplies the first HVAC Unit. The total load is 225 CFH and the total length

is 25 ft. + 75 ft. = 100 ft. Refer to Table 11 under the 100 ft. column. We find that 1/2 inch (PGP-8) has

capacity of 225 CFH (363). Use 1/2 inch (PGP-8) to run Section D.

7. Sizing Section E – Section E supplies the second HVAC Unit. The total load is 225 CFH and the total

length is 25 ft. + 75 ft. = 100 ft. Refer to Table 11 under the 100 ft. column. We find that 1/2 inch (PGP-8)

has capacity of 225 CFH (363). Use 1/2 inch (PGP-8) to run Section E.

8. Sizing Section F – Section F supplies the third HVAC Unit. The total load is 225 CFH and the total length

is 75 ft. + 25 ft. + 25 ft. = 125 ft. Referring to Table 11 under the 125 ft. column, we find that 1/2 inch

(PGP-8) has capacity above 225CFH (326). Use 1/2 inch (PGP-8) to run Section F.

Parallel Elevated System

Appliance Loads

Lengths

Tube Size

-

A = 75 ft.

PGP-16 (1")

B = 25 ft.

PGP-16 (1")

C = 25 ft.

PGP-12 (3/4")

HVAC Unit (225 CFH)

D = 25 ft.

PGP-12 (3/4")

HVAC Unit (225 CFH)

E = 25 ft.

PGP-8 (1/2")

HVAC Unit (225 CFH)

F = 25 ft.

PGP-8 (1/2")

HVAC Unit (225 CFH)

G = 25 ft.

PGP-8 (1/2")

HVAC Unit (225 CFH)

H = 25 ft.

PGP-8 (1/2")

HVAC Unit (225 CFH)

I = 25 ft.

PGP-8 (1/2")

Total 1,350 CFH