Parker Hannifin Corporation

Parflex Division

Ravenna, Ohio

Bulletin No. 4660-PGP2T

1

Parflex

®

Flexible Gas Piping System

Design and Installation Guide

Section 3.0 System Configuration & Sizing

3.2 System Sizing Methods and Examples

3.2.1

Sizing Methods

Longest Length Method

– The method to size gas piping that take into count the pressure at the down

stream end of the meter and the furthest appliance. The piping in the system should be sized large

enough to accommodate the entire system load.

Dual Pressure Method

– The pressure down stream of the primary regulator is elevated most commonly to

2 psig or 5 psig. A secondary regulator is located before the manifold.

Elevated Pressure Method

– Higher pressure is run through a system to each appliance. In this method, a

regulator will be placed in front of each appliance.

Summation Method –

The summation method is used for gas pipe sizing, the pressure losses through the

pipe should be considered as to allow minimum pressure and volume of gas to the appliance. Sizing

can be accomplished by calculations based on summation of line pressure drops and exact appliance

loads. The pressure drop summation method is more precise than the longest length method and may

permit the use of smaller diameter tubing in some installations. Pressures should be sufficient to

manufacturer’s input rating and the local authority.

3.2.2

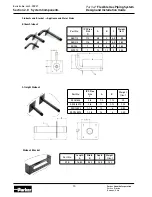

Longest Length Series System Example (Low Pressure)

This is a low pressure series system with four natural

gas appliances. The utility company supply pressure

exiting the meter is 6 inches water column, and the

minimum continuous inlet pressure required by the

appliances is 5 1/2 inches water column. The maxi-

mum allowable pressure drop across the longest

length from the meter to the farthest appliance is 1/2

inch water column. The gas supplied has a specific

gravity of .60 and an energy content of 1 cubic foot

per hour equals 1,000 BTU per hour. Reference Sizing

Table 1, Section 7.1, for sizing charts.

1. Determine the total gas load for each appliance

in cubic feet per hour:

Furnace ...................... 75 CFH (75,000 BTUH/1000 BTUH per CFH)

Oven/range ................ 50 CFH (50,000 BTUH/1000 BTUH per CFH)

Dryer .......................... 25 CFH (25,000 BTUH/1000 BTUH per CFH)

Water heater .............. 34 CFH (34,000 BTUH/1000 BTUH per CFH)

Total ........................... 184 CFH

2. Measure the length of each run and determine the maximum length from the meter to the farthest ap-

pliance.

A = 8 ft., B = 10 ft., C = 12 ft., D = 20 ft., E = 2 ft., F = 6 ft. G = 8 ft.

Furnace = A + F = 8 ft. + 6 ft. = 14 ft.

Oven/range = A + B + E = 8 ft. + 10 ft. + 2 ft. = 20 ft.

Dryer = A + B + C + G = 8 ft. + 10 ft. + 12 ft. + 8 ft. = 38 ft.

Water heater = A + B + C + D = 8 ft. + 10 ft. + 12 ft. + 20 ft. = 50 ft.

The longest run is from the meter to the water heater is 50 ft.

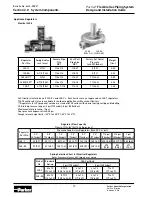

3. Sizing Section A—Length A must be sized to handle the total load of all appliances and the total pres-

sure drop from the meter to the farthest appliance. The total appliance load is 184 CFH. Using the

longest length sizing method, the length is 50 ft. to the water heater. Referring to Table 1 (0.5 psig or

less; pressure drop 0.5 in. WC) under the 50 ft. length column, we find that 1 inch size (PGP-16) has a

flow capacity exceeding 184 CFH (186 CFH). Use 1 inch tubing (PGP-16) to run Section A.

4. Sizing Section B—Section B must supply the water heater, dryer, and range. The total pressure drop

for the system is considered to be from the meter to the water heater (farthest appliance). The total

appliance load is 34 + 25 + 50 = 109 CFH. Using the longest length sizing method, the length is 50 ft.

(distance from meter to water heater). Referring to Table 1 under the 50 ft. length column, we find that

size 1 inch (PGP-16) has flow capacity over 109 CFH (186). Use 1 inch (PGP-16) to run Section B.

Low Pressure Natural Gas System (Series)