© MOOG 2010

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

3

MRJ04410

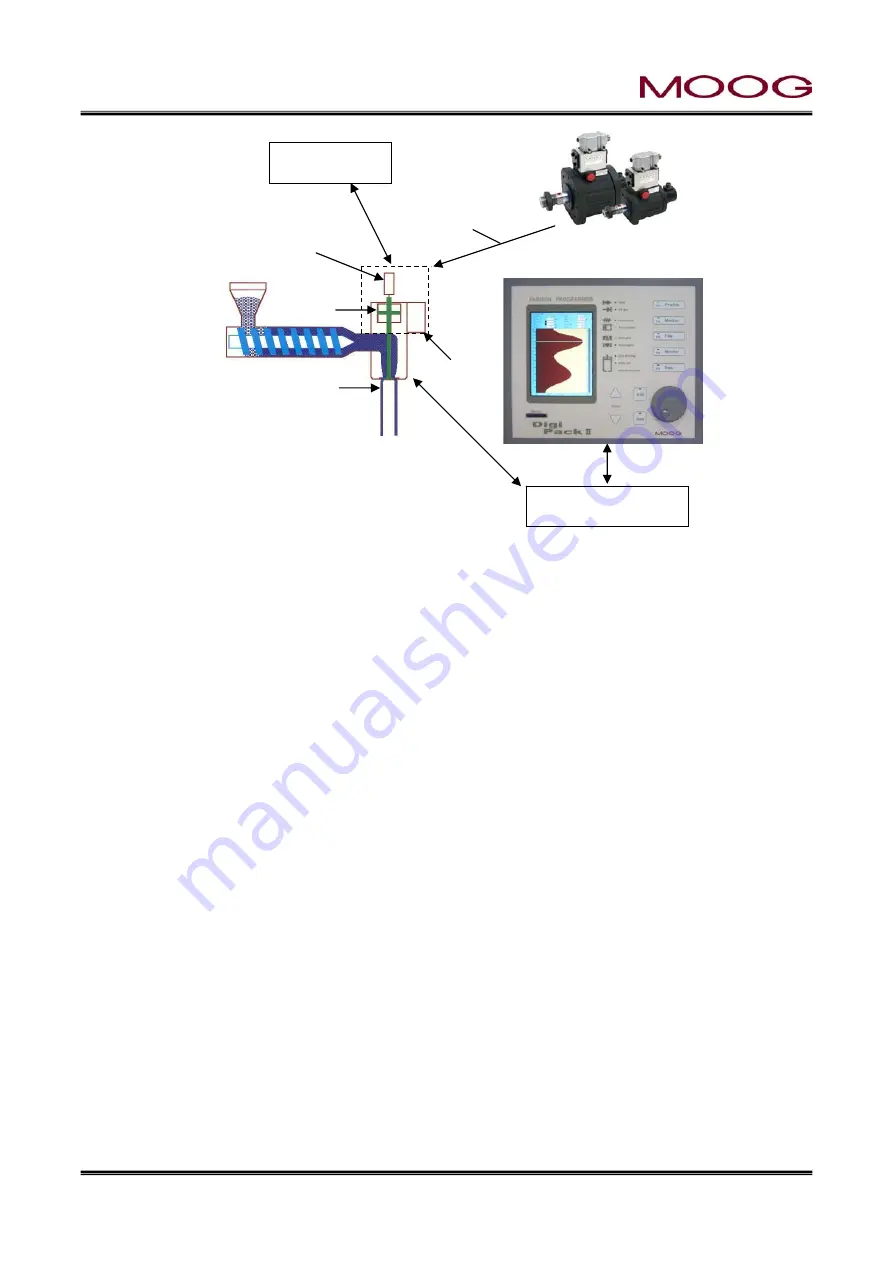

When used with continuous blow molding machines, the DigiPackⅡcontrols the parison wall thickness

relative to the machine cycle time. The machine cycle starts when the parison cutoff knife cuts the parison

off. Cycle time may be determined by:

a)

a fixed, operator set cycle time or,

b)

an automatic cycle time, set by repeated measurement of the time between parison knife cuts or

c)

using a fixed DigiPackⅡtime cycle and having the DigiPackⅡinitiate a machine function such as

closing or moving the mold.

The shape of the parison wall profile is set digitally by the operator. The size of the die gap, measured by a

die gap position transducer, is compared with the operators commanded position as set on the DigiPackⅡ

display.

The error between the operators set position and the actual position causes the servovalve to flow oil to

the actuator to reduce the position error to a very small value. This feedback process ensures that the

actual die gap follows the commanded die gap very accurately.

When used with accumulator machines, the DigiPackⅡcontrols the parison wall thickness relative to the

accumulator position as the plastic is being extruded.

As the total quantity or volume of plastic extruded is proportional to the accumulator position, then it

follows that the resulting parison wall thickness at any given point on the length of the container must be

related to the accumulator position. Given that the physical properties of the plastic and its temperature

are constant from container to container, then each container’s weight and strength will be consistent.

Hydraulics

Die Gap

Tooling

Actuator

PLC Controller

Servovalve

Actuator

DCDT Die Gap Posi-

tion Transducer

Parison Cutoff Knife

Figure 1-1 Basic Continuous Blow Molding Machine Control Diagram