Lucent Technologies Lineage

®

2000 100A Ferroresonant Rectifier J85503A-1

Issue 6 October 1998

Testing 6 - 1

6

Testing

Introduction

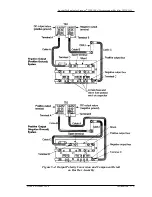

This section gives test procedures for newly installed and/or

operating rectifiers. If the plant in which a rectifier is being

installed has never been operational, the plant and controller

tests must be performed before the rectifier tests. Consult the

plant and controller product manuals for their installation test

procedures.

Rectifiers can be tested on or off line. “On line” means a battery

string and/or office load is connected to the rectifier. A dummy

test load and a Battery Plant Simulator Test Set are required for

testing off line. See “Tools and Test Equipment” later in this

section for a description of these items. For troubleshooting and

diagnostic procedures, refer to Section 7, Troubleshooting and

Adjustments. Those unfamiliar with the function of rectifier

controls and indicators should read Section 2, Product

Description.

Precautions

When working on power systems, observe safety precautions in

Section 4 and those within each procedure.

•

The ac input voltage powers certain control relays, the

Rectifier Failure Alarm (RFA), and the ac contactor.

Voltage is available to these circuits whenever the ac

service is available to the rectifier.

•

Remote sensing of rectifier output occurs via the plant

control cable connected to P2A on control board CM2. This

cable must be disconnected when internal sensing is

desired, as when testing off line, using a test load.