Lucent Technologies Lineage

®

2000 100A Ferroresonant Rectifier J85503A-1

5 - 4 Installation

Issue 6 October 1998

DC Output Power

The majority of dc power plants for telecommunication

applications are designed to use single conductor cables (in

parallel for current capacity or to limit voltage drop) supported

on ladder racks. Experience has shown that the use of flexible

cables (welding type cables) makes installation of this type

wiring much simpler. Therefore, the terminals are sized to fit

KS-24194 L2 wire, which is very flexible.

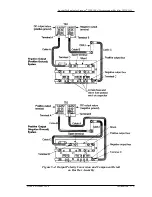

Figure 5-1 shows the dc output conduit hole and alternate hole.

Figure 5-2 shows the dc output wire termination points. Table

5-B specifies the dc output cable size, T&B connectors, and

crimp die. Also see note 57 on J-drawing, J85503A-1.

Installation Tools

The following tools are required for installing rectifiers:

•

Material handling equipment to unload rectifiers at site,

remove them from shipping containers, and place them in

final positions

•

Common electrician's hand tools, including jeweler's

screwdriver, electrical tape, wire cutters and strippers, 14

AWG

to 2

AWG

wire

•

Proper crimping tools and dies for connectors used in the

installation.

Table 5-B: DC Output Requirements

Amps

Output

Wire

Size*

Output

Conduit

Trade Size

(inches)

Connectors

Required

T&B

Crimp

Die

100

#2 AWG

1-1/4

2 studs

(5/16" dia., 7/8"

apart) T&B

54858BE

(2-hole crimp lug)

Green

* Use KS-24194 L2 wire. It is a flexible, stranded copper wire,

rated 600 volts; stranding meets American Society for Testing

and Materials (ASTM) B 172 Class I. This non-halogen,

insulated wire is rated 90°C. The insulation has a

combustibility rating of 28% minimum as determined by

ASTM D2863. Wire sizes were chosen to limit the voltage

drop to 2 volts where the cable loop is approximately 200 feet.