Detailed Function Description

59

Notice:

z

When running at torque control mode, the acceleration time has nothing to

do with P0.11.

z

The 100% of torque setting is corresponding to 100% of P3.14 (Torque limit).

For example, if torque setting source is keypad (P3.12=1), P3.13=80% and

P3.14=90%, then

Actual torque setting = 80% (P3.13) * 90% (P3.14) = 72%.

6.5 P4 Group --V/F Control

Function

Code

Name

Description

Setting

Range

Factory

Setting

P4.00

V/F

curve

selection

0:Linear curve

1: User-defined curve

2: Torque_stepdown curve (1.3 order)

3: Torque_stepdown curve (1.7 order)

4: Torque_stepdown curve (2.0 order)

0~4 0

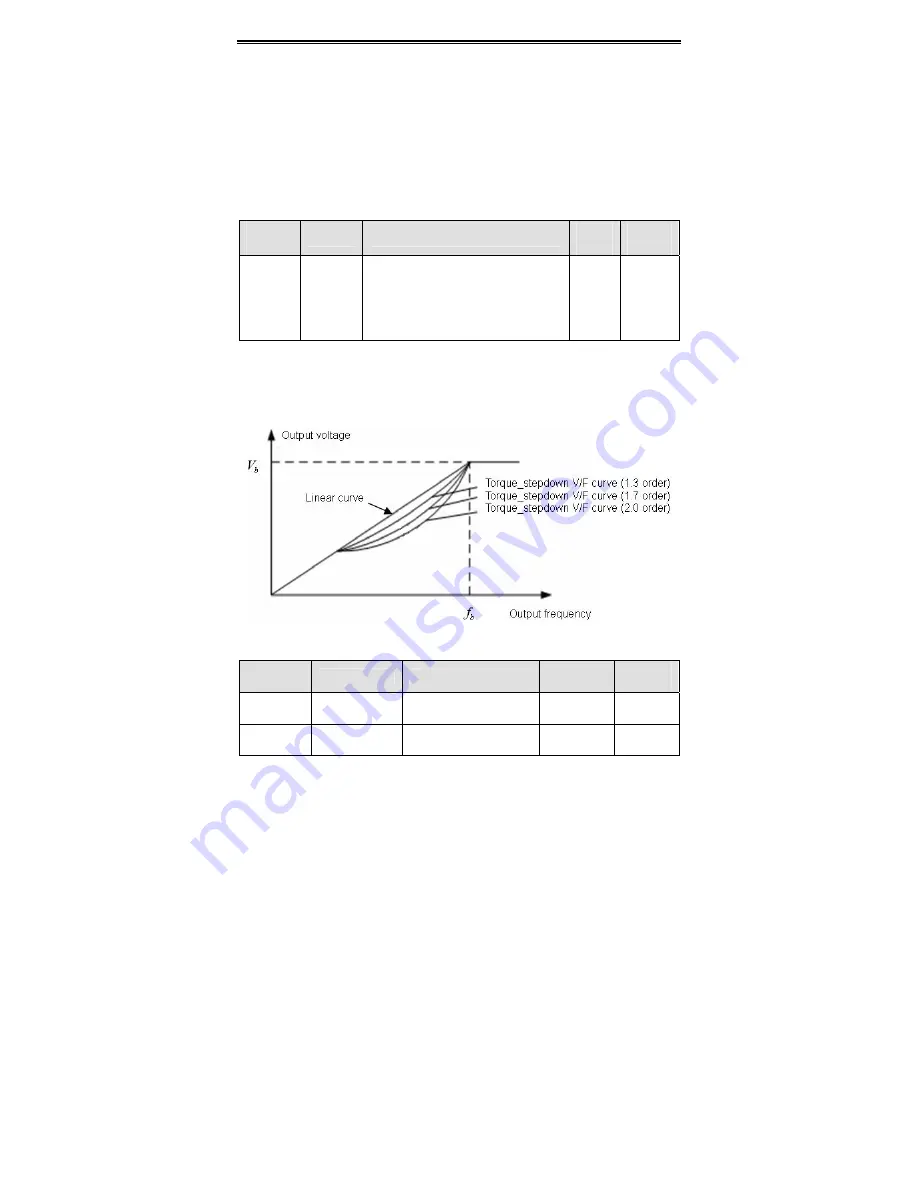

0: Linear curve. It is applicable for normal constant torque load.

1: User-defined curve. It can be defined through setting (P4.03~P4.08).

2~4: Torque_stepdown curve. It is applicable for variable torque load, such as blower,

pump and so on. Please refer to following figure.

Figure 6.10 Multiple V/F curve diagram.

Function

Code

Name

Description

Setting

Range

Factory

Setting

P4.01 Torque

boost

0.0%: auto

0.1

%

~10.0

%

0.0~10.0 1.0

%

P4.02

Torque boost

cut-off

0.0%~50.0% (motor

rated frequency)

0.0~50.0 20.0%

Содержание CHV Series

Страница 2: ......

Страница 12: ...Introduction 4 1 4 Parts Description Figure 1 2 Parts of inverter 15kw and below...

Страница 13: ...Introduction 5 Figure 1 3 Parts of inverters 18 5KW and above...

Страница 23: ...Disassemble and Installation 15 Figure 3 7 Disassembly of metal plate cover Figure 3 8 Open inverter cabinet...

Страница 25: ...Wiring 17 4 1 Connections of Peripheral Devices Figure 4 1 Connections of peripheral devices...