amount protruding on both ends of the wing Using

thin CA, glue the front (beveled) edge of the leading

edge sheeting to the back edge of the leading edge.

Now wet the top surface of the sheeting (if necessary)

to make it bend easier Apply thick CA glue to the top

edge of the ribs and to the front half of the spar Then

immediately bend the sheeting down onto the ribs and

spar Hold the sheeting down with long strips of

masking tape until the glue has set.

D D 15 Using the 3/32" x 3" x 11-1/8" balsa sheets,

glue the top center section sheeting in place as

shown on the plan (Use the scraps trimmed from the

LE sheeting if needed for the aft pieces).

D D 16 From the 3/32" x 3/8" x 36" balsa sticks, cut

and glue cap strips to the top edges of all exposed

ribs, from the TE sheeting to the LE sheeting HINT:

For easier positioning of the cap strips, first mark the

location of each rib on the LE and TE sheeting

D D 17. Remove the wing panel from the building

board Check all glue joints, adding glue as

necessary.

D D 18. Using a razor saw and a sanding block,

carefully cut off and sand all excess sheeting spars,

LE and TE even with W-1 and W-13. Sand the TE

sheeting flush with the TE.

FOR FIXED LANDING GEAR, perform steps 1 9 - 2 2

D D 19 Trial fit the long grooved hardwood LG

block into the notches in ribs W-2, W-3 and W-4 (see

the wing plan for proper positioning) File the notches

if necessary for a good fit. Now use epoxy to securely

glue the block in place.

D D 20. Epoxy the 1/2" x 3/4" x 1-1/2" hardwood

block to the LG block and to the 1/8" ply doubter on

rib W-2, as shown on the plan and in the photo Then

epoxy the 1/2" x 3/4" x 1/2" hardwood block to the

other end of the LG block and to the 1/8" ply doubler

on rib W-4.

D D 21 Drill a 3/16" hole down through the grooved

LG block and the 1-1/2" block Line up the drill so you

are drilling straight down through the middle of the 1-

1/2" block.

D D 22 Trial fit the 3/16" diameter main landing

gear wire into the landing gear block at this time Cut

or file the groove and hole in the landing gear block as

necessary for a good fit

FOR RETRACTS, perform steps 23 - 31

NOTE: In the Ultra-Sport 1000 prototype we used

B&D mechanical retracts, and you will see them in the

photographs You may use whatever type of retracts

you prefer, as long as they are of the correct size for

this airplane (see the introductory remarks at the

beginning of this book) If you are using B&D retracts,

it will be necessary to drill them out to accept the 3/16"

wire struts supplied in this kit (see below*) It is also

recommended that you file a "flat" on the 3/16" struts

at the set screw location, to prevent the struts from

turning You should wait until the retracts have been

installed before doing so, to insure proper alignment

(See Step 30).

instructions for drilling B&D retracts. Back out the set

screw so it won't interfere with the drill Drill out the

strut hole first with an 11/64" bit, then a 3/16" bit If it

is difficult to insert the strut, re-drill the hole with a #12

(.189") drill bit Stop drilling as soon as you feel the

bit bottom out in the hole. Temporarily install the

gear strut, tighten the setscrew, and check operation.

Due to the larger strut, the setscrew may bind against

the actuator arm and prevent full retraction If this is

the case, you'll have to file a small amount off the top

of the set screw Do this by drilling a 5/32" hole in a

scrap piece of hardwood, screwing the set screw in

with 1/32" protruding, and filing off the top of the set

screw.

NOTE: Most standard wheels have a 5/32" diameter

axle hole, so you'll have to drill the hubs of your

wheels to fit the 3/16" diameter landing gear wire

supplied in this kit Start by using a 3/16" drill bit, but

because the nylon hub material is somewhat flexible, it

may be necessary to use a 13/64" drill bit to get the

hole large enough to allow the wheel to turn freely.

17

Содержание Ultra-Sport 1000

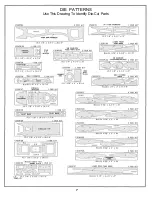

Страница 7: ...7 DIE PATTERNS Use This Drawing To Identify Die Cut Parts...

Страница 57: ...57...

Страница 59: ...2 View Drawing Use This For Planning Your Trim Scheme 59...