D 4 Using a sanding block and coarse (50 or 80-grit)

sandpaper, sand both sides of the elevators to a taper

as shown on the plans. The trailing edge should end

up approximately 1/16" wide. (See photo proceeding

page.)

D 5 Select the two softest (lightest) 1/16" x 3" x 30"

balsa sheets, and use them to sheet both sides of the

elevators Make sure you obtain a good glue bond

between the sheeting and the internal structure.

D 6. Sand the leading edge of the elevators to a "V-

shape" as shown on the plan Sand the trailing edge

to a slightly rounded shape Do not round the elevator

ends (leave them square)

between the stab sheeting and the stab

framework, especially in the center, therefore, we

recommend using 30-minute epoxy when you apply

the final piece of sheeting Spread the epoxy evenly

but sparingly, to avoid excess weight

D 6 Cut one end of the two 1/2" x 2" x 14-7/8" balsa

stab leading edges to match the plan at the stab

centerline Glue the leading edges to the stab

framework Cut and sand the ends of the leading

edges to match the ends of the stab.

D 7 Glue the 1/2" x 1" x 6-1/4" balsa stab tips to the

ends of the stab Trim and sand the front ends of the

stab tips to match the plan

BUILD THE STABILIZER

NOTE: You will construct the stab framework and

add the 1/16" balsa sheeting, then, you will add the

1/2" balsa leading edges and tips.

D 1 Accurately pin the 3/8" x 3/4" x 26-3/4" balsa

stab TE onto the plan.

D 8 Temporarily tape the elevators to the stab.

While holding the elevators in the neutral position,

sand the 1/2" x 1" stab tips to match the elevator.

D 2 Trial fit the 3/8" x 2-3/4" x 5" balsa stab center

and the triangle-shaped 3/8" ply spar* in place on the

plan. The leading edge of the spar should line up with

the lines on the plan If not, sand the edges of the

balsa stab center until these parts line up correctly

Securely glue the stab center to the stab TE, and glue

the spar to the stab center.

*NOTE: It is common for the 3/8" ply to be slightly

thinner than the 3/8" balsa For this reason, we have

included a 1/32" x 1-1/4" x 11-1/2" ply sheet If the

spar in your kit is thinner than the 3/8" balsa stab

center, glue the 1/32" ply sheet to the spar, and trim

the edges to match the spar.

D 3 Complete the stab framework by cutting and

fitting pieces of 1/8" x 3/8" x 30" balsa, as shown on

the plan. Glue this assembly together.

D 4 Remove the stab framework from the building

board and sand both sides and all edges smooth.

D 5. There are four remaining 1/16" x 3" x 30" balsa

sheets Edge glue these sheets together in pairs to

make two 6" x 30" sheets, and sand both sides

smooth with a sanding block Use these to sheet the

top and bottom of the stab framework NOTE: It is

essential to get a strong and complete bond

D 9 Draw a centerline on the stab leading edge and

tips, which will help to maintain symmetry while

sanding.

D 10. Using a sanding block, sand the stab leading

edge to the approximate shape as shown in the stab

cross-section on the plan Sand the stab tips to a

rounded shape.

TEMPORARILY INSTALL HINGES

D 1 Using the plans as a guide, mark the hinge

locations on the stab, elevators, fin and rudder.

NOTE: There are many types of good hinges on the

market, and everyone has their personal preferences,

therefore, hinges have not been included in this kit.

The current favorite for many modelers is the type of

laminated hinge that permits hinge slotting with an

X-acto knife, and gluing with thin CA adhesive If you

are building a taildragger, heavy-duty hinges are

recommended for the rudder See the IMAA Safety

Guidelines in the Appendix at the end of this book.

11

Содержание Ultra-Sport 1000

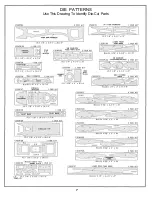

Страница 7: ...7 DIE PATTERNS Use This Drawing To Identify Die Cut Parts...

Страница 57: ...57...

Страница 59: ...2 View Drawing Use This For Planning Your Trim Scheme 59...