7

PRO-VISION rev.04

PRO-VISION

Do not install rigid conduit into electrical

knockouts. Only nylon cable glands are

permitted for cable or wire fastening.

The controller has no power-on switch.

An external switch or circuit breaker

shall be included in the building instal-

lation to interrupt power to L and N

electric power lines. It shall be in close

proximity to the equipment and within

easy reach of the operator. It shall be

marked as the disconnecting device for

the equipment.

Alarm Connection

2.2.2.

There are two types of alarms on the market.

One type activates when current is cut off at its

input; the other type of alarm activates when

current is supplied at its input. For an alarm of

the first type, use the NC terminal as shown on

the wiring diagram. For an alarm of the second

type, use the NO terminal.

2.2.3. Sensor Inputs

Sensors operate at low voltage and are

isolated from the supply. Make sure that

sensor cables remain isolated from all high

voltage sources. In particular, do not route

the sensor cables through the same electri-

cal knockout as other cables. Do not connect

the shield from the sensor cable to a terminal

or a ground.

Extending a sensor:

Each sensor can be ex-

tended up to 500 feet (150 meters).

To extend a sensor: Use a shielded cable of

outside diameter between 0.245 and 0.260 in

(6.22 and 6.60 mm) (the cable dimensions

should not be under 18 AWG) to ensure the

cable entry is liquid tight.

Do not ground the

shielding.

It is preferable to solder the cable joint to

ensure a proper contact between the two

cables.

1

4

7

DEL

2

5

8

0

3

6

9

+/-

AM/PM

ENTER

BACK

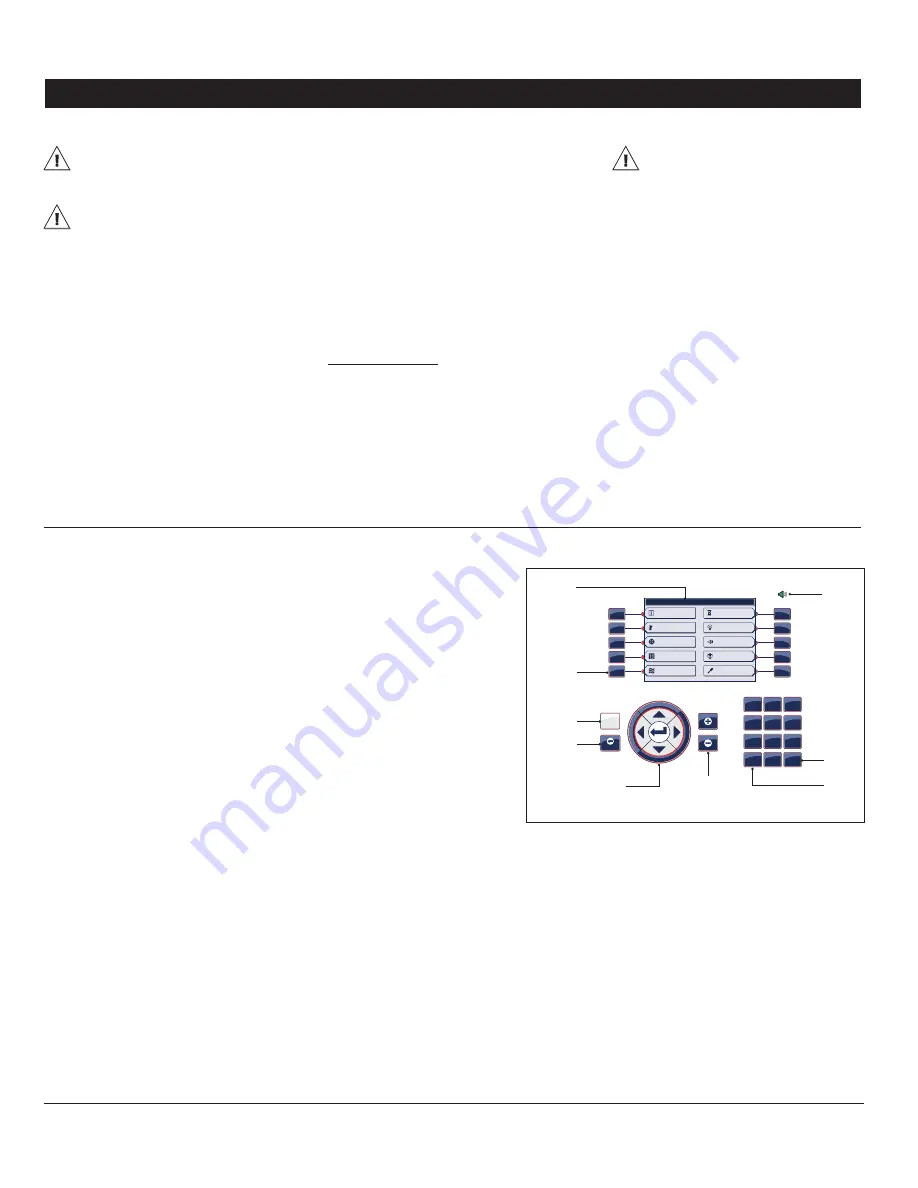

Main Menu

Current conditions

Set Point

Minimum ventilation

On/Off Settings

Inlets/Vents

Start flock / Egg

Light Programs

Alarms

History

Set-up

MAIN

MENU

Menu

Selectors

Graphic

LCD

Display

Alarm

Status

LED

Home

Key

Back

button

Arrow keys

(Right = Page-Down

Left = Page-Up)

Adjustment

Buttons

Digital Keypad

+/-

AM/PM

Button

Delete

Do not run sensor cables next to other

power cables. When crossing over other

cables, cross at 90°.

Defective sensors:

An alarm is generated

when a defective sensor is detected. Defec-

tive sensors are identified in the

“Alarm”

menu. Refer to chapter 13 for further

information on the alarms.

2.2.4. 0-10V Output Connection

It is recommended to use a 18 to 22 AWG

wire to connect the devices to the 0-10V

outputs. This type of output can be used to

connect various devices such as lights.

3. USER INTERFACE

3.1. Location of the Controls

Graphic LCD display —

The large graphic

LCD screen is used to display the parameters

and menus.

Menu selectors —

The menu selectors allow

selecting a tab on screen.

Home key —

This short-cut key provides ac-

cess to the main menu.

Back —

The

“Back”

key is used to go back to

the previous menu.

Arrow keys —

The arrow keys allow select-

ing a parameter on screen. The right and

left arrow keys can also be used to move

through the display by pages (left=page-up,

right=page-down).

Enter —

The

“Enter”

key is used to change

the value of non-numerical parameters.

Pressing this key makes a drop-down choice

menu appear.

Adjustment buttons —

The adjustment but-

tons allow increasing or decreasing the value

of a parameter.

Delete —

The delete key allows

clearing the last digit that has

been posted while editing a

numerical value.

+/- & AM/PM button —

This

push-button allows entering

a negative value and allows

changing the AM/PM time in-

dicator.

Digital keypad —

The digital key-

pad is used to modify the value

of numerical parameters.

Alarm Status LED —

The alarm

LED turns red when an alarm

situation is active or turns green

when there is no alarm.

3.2. Adjusting a Parameter

When a parameter is selected, the control-

ler gives indications about the way it can

be modified at the bottom of the screen. A

parameter can either be modified with the

adjustment buttons, with the digital keypad or

by pressing the

“Enter”

key and then selecting

an item from a drop-down menu. Follow the

instructions on screen to modify the value

of a parameter.

Содержание PRO-VISION

Страница 54: ...PRO VISION NOTES NOTAS...

Страница 55: ...PRO VISION NOTES NOTAS...