3 - CONTROLS AND INSTRUMENTS

Display

Description

Corrective action

Start Engine to

check Emission

System

Engine start required to

perform the system reset.

Validation re-start counter

is enabled Follow the

instructions on the machine

display.

See your local authorized dealer for repair.

Operate Engine at

High Speed and

Load

Exhaust temperature is low.

Operate the machine for

approximately

20 min

at

a minimum of

50%

load

to check the SCR system

performance.

See your local authorized dealer for repair.

Maintain Current

Conditions. Test In

Progress

SCR system test in progress.

Maintain current operating

conditions. If all three

validation re-starts have been

used and the system has not

been reset, the machine is

limited to emergency re-starts

only.

See your local authorized dealer for repair.

DEF/A

D

B

LUE

®

Level LOW

DEF/A

D

B

LUE

®

level is less

than

10%

of tank volume.

No engine power loss at this

level

Fill the

DEF/A

D

B

LUE

®

tank.

Poor

DEF/

A

D

B

LUE

®

quality

detected

Poor

DEF/A

D

B

LUE

®

quality

detected. After the engine

has run for

50 min

with poor

DEF/A

D

B

LUE

®

quality, there

will be a torque and speed

reduction.

Drain the tank. Replace

DEF/A

D

B

LUE

®

.

NOTE:

see “

DEF/A

D

B

LUE

®

tank refilling” section for important

tank draining information.

DEF/A

D

B

LUE

®

Injection Failed,

Power Limited

Technical failure detected.

25%

torque reduction ramped

in within

25 min

. Further

torque/speed reduction

2 h

after initial fault detection.

Contact your authorized dealer.

Fuel

Low fuel

Fill the fuel tank - do not allow the tank to totally empty.

3-76

Содержание 721G Stage IV

Страница 24: ...1 GENERAL INFORMATION Waste Handler WH configuration LEIL18WHL1118FB 3 721G 1 18 ...

Страница 26: ...1 GENERAL INFORMATION LEIL17WHL2018FB 5 821G 1 20 ...

Страница 29: ...1 GENERAL INFORMATION LEIL19WHL0584H 1 1 23 ...

Страница 30: ...1 GENERAL INFORMATION 1 24 ...

Страница 51: ...2 SAFETY INFORMATION Empty tool LEEN11T0024AA 20 2 21 ...

Страница 84: ...2 SAFETY INFORMATION 2 54 ...

Страница 154: ...3 CONTROLS AND INSTRUMENTS Select the passcode to delete from the system and con firm LEIL16WHL1551AA 96 3 70 ...

Страница 162: ...3 CONTROLS AND INSTRUMENTS Inducement and validation re starts LEIL14WHL0394HA 2 3 78 ...

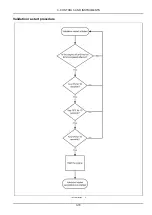

Страница 163: ...3 CONTROLS AND INSTRUMENTS Validation re start procedure LEIL15WHL0608HA 3 3 79 ...

Страница 189: ...4 OPERATING INSTRUCTIONS RCPH10WHL045BAH 7 4 15 ...

Страница 191: ...4 OPERATING INSTRUCTIONS RCPH10WHL045BAH 9 4 17 ...

Страница 193: ...4 OPERATING INSTRUCTIONS RCPH10WHL045BAH 12 4 19 ...

Страница 208: ...4 OPERATING INSTRUCTIONS 4 34 ...

Страница 222: ...5 TRANSPORT OPERATIONS 5 14 ...

Страница 259: ...7 MAINTENANCE LEIL17WHL1665H 5 721G 7 21 ...

Страница 260: ...7 MAINTENANCE LEIL17WHL1665H 6 821G 7 22 ...

Страница 265: ...7 MAINTENANCE DEF AdBlue level faults failures and engine power loss levels LEIL15WHL0607HA 2 7 27 ...

Страница 266: ...7 MAINTENANCE DEF AdBlue quality faults failures and engine power loss levels LEIL15WHL0609HA 3 7 28 ...

Страница 267: ...7 MAINTENANCE DEF AdBlue technical faults LEIL14WHL0392HA 4 7 29 ...

Страница 291: ...7 MAINTENANCE LEIL18WHL1152AA 14 821G 7 53 ...

Страница 300: ...7 MAINTENANCE LEIL15WHL1846AB 2 821G 7 62 ...

Страница 313: ...7 MAINTENANCE LEIL18WHL1154FA 1 LEIL18WHL1155FA 2 7 75 ...

Страница 360: ...7 MAINTENANCE 9 Re install all the covers guards and steps previously removed 7 122 ...

Страница 417: ...7 MAINTENANCE Waste Handler WH models LEIL17WHL2020FA 2 7 179 ...

Страница 436: ...8 SPECIFICATIONS 721G Loader Lift Arms Specifications LEIL16WHL0629FB 1 8 10 ...

Страница 445: ...8 SPECIFICATIONS LEIL16WHL0629FB 4 8 19 ...

Страница 461: ...8 SPECIFICATIONS LEIL16WHL0629FB 10 8 35 ...

Страница 470: ...8 SPECIFICATIONS LEIL16WHL0629FB 13 8 44 ...

Страница 480: ...8 SPECIFICATIONS 8 54 ...

Страница 516: ...9 ACCESSORIES 9 36 ...

Страница 520: ...Windows 3 86 Windshield washer fluid level Check 7 163 ...

Страница 521: ......