5. Technical Safety Inspection and Preventive Maintenance

1 / 2 0 1 0

5 - 10

BA-TE-DE08C M.KAY

SW9xx_SM_Chapter 5-1_1-2010.doc/pdf <110301> yymmdd

B. Braun Avitum AG

Dialog

+

SW 9.xx

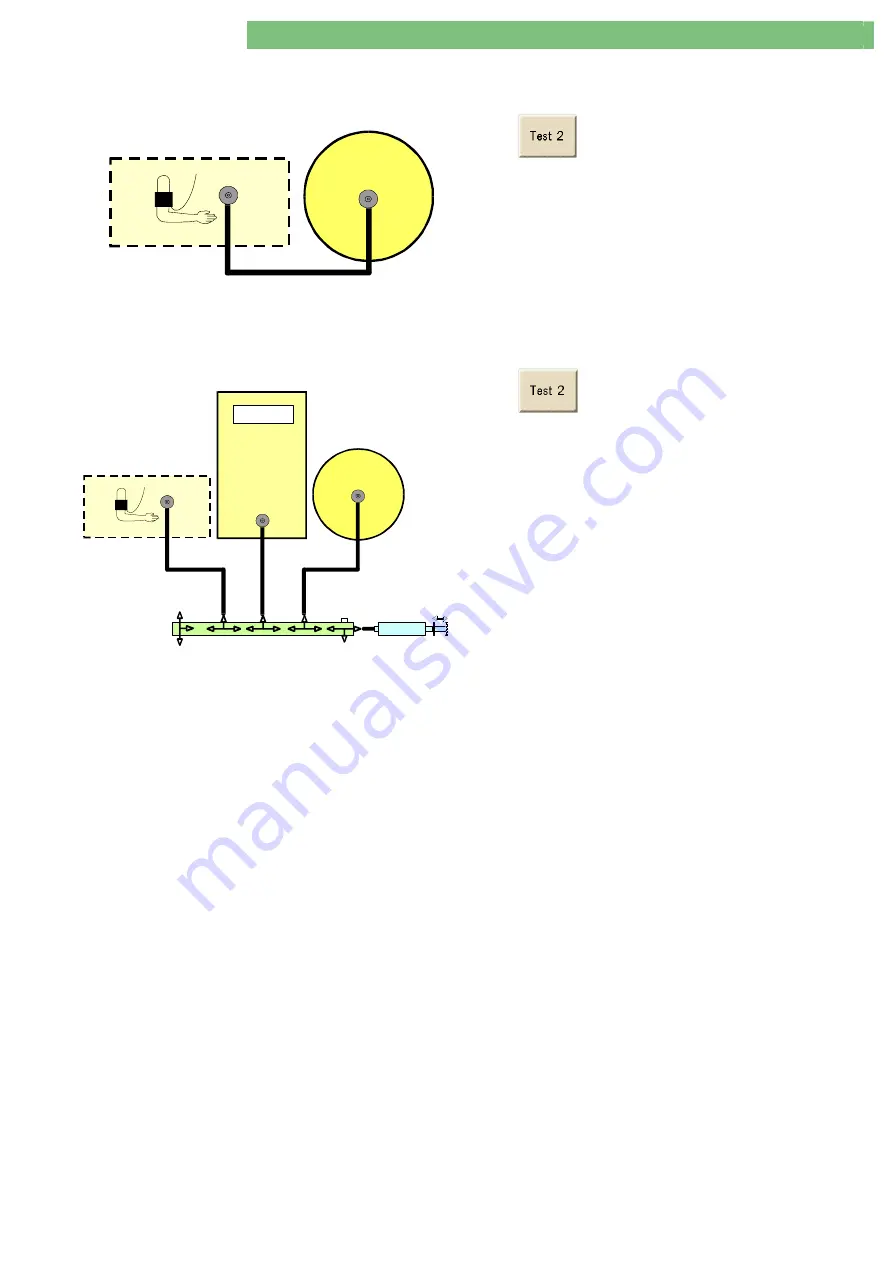

To Point 3: Air Leakage

500 ml

Measurement

Chamber

Pressure Tube

ABPM

Fig.: Inspection Set-Up for Inspection of Air Leakage

1.

Set-up and connect ABPM according to figure.

2.

Press

button.

A test pressure of approx. 200 mmHg is automatically built

up (test duration 4 minutes).

3.

Enter values in table after test is expired.

The values are displayed after the time has elapsed:

The Initial Pressure, Final Pressure and Leakage are displayed

in the ABPM Maintenance menu point 4.

Pressure drop ABPM module:-----------------------

≤

18 mmHg

To Point 4: Rapid Exhaust

500 ml

Reference Instrument

Measurement

Chamber

50 ml Syringe

Pressure Tube

1

2

3

4

ABPM

Stopcock System

50 ml

Fig.: Inspection Set-up for Rapid Exhaust

1.

Press

button.

Wait until a pressure build-up of approx. 290 mmHg (start of

pressure retention phase).

2.

Increase slowly pressure to > 300 mmHg with the syringe

until valve opens for rapid exhaust.

3.

The valve for rapid exhaust must open between 300 and 330

mmHg. The indicated time for the pressure drop must not be

exceeded.

Pressure reduction from >260 mmHg to <15 mmHg

: ---- max. 10 s