Installing the Printer

Chapter 1: Getting Started

❖

1-19

7

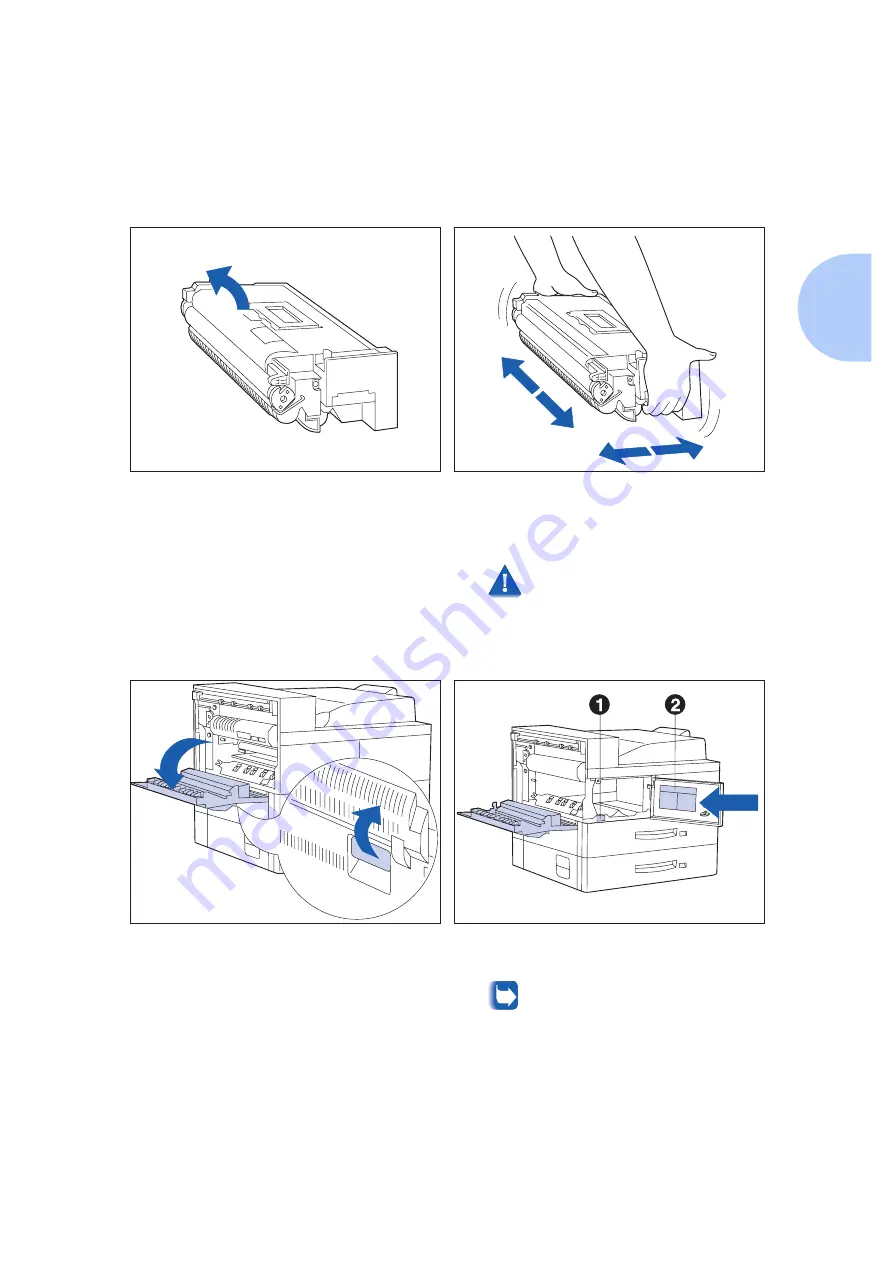

Remove the Toner Cartridge from its package

and pull out the protective paper sheet from

the drum shutter.

8

Hold the Toner Cartridge horizontally and

gently shake it 5 to 6 times to evenly distribute

the toner inside.

Print quality may be degraded if the

toner is not evenly distributed. If the

toner is not freed by shaking the

cartridge, you may hear a noise when

powering ON the printer, and the

cartridge may be damaged.

9

Open Door A.

10

Open the front cover.

This reveals the serial number (1) and

toner install instructions (2).

Summary of Contents for DP N24

Page 1: ...DP N24 N32 and N40 Network Laser Printers System Administrator Guide ...

Page 38: ...Technical Support 1 30 DP N24 N32 and N40 System Administrator Guide ...

Page 156: ...Reset Menu 3 92 DP N24 N32 and N40 System Administrator Guide ...

Page 220: ...Print Quality Problems 6 46 DP N24 N32 and N40 System Administrator Guide ...

Page 221: ...Appendix A DP N40 Ordering Information A 1 DP N40 Ordering Information A p p e n d i x A ...

Page 224: ...DP N40 Ordering Information A 4 DP N24 N32 and N40 System Administrator Guide ...

Page 310: ...PostScript Fonts D 6 DP N24 N32 and N40 System Administrator Guide ...

Page 311: ...Appendix E Printer Specifications E 1 Printer Specifications A p p e n d i x E ...

Page 314: ...Printer Specifications E 4 DP N24 N32 and N40 System Administrator Guide ...

Page 322: ...PJL Commands F 8 DP N24 N32 and N40 System Administrator Guide ...