Page 76

Troubleshooting

Integrated Modules

Integrated Modules

4-15

#826498 - Revision B - December, 2016

Testing of Gas Pressure

Testing gas supply pressure to a unit is a critical tool in properly diagnosing a problem. Gas supply pressure issues

are common and many times are the root cause of reoccurring issues. On the modules each burner has an individ-

ual spark module. On the CG152TF/S there is no fuel/air ratio adjustments. On the MM15TF/S there is a fuel/air

adjustment set at the factory. Intermittent sparking issues, flame quality issues, and ignition issues are almost

always related to gas supply or supply regulator issues. Different sized burner assemblies are affected in different

ways by gas issues. Gas pressure must be checked by the Wolf proscribed method to produce results that can be

used to diagnose a specific issue.

Natural Gas Specifications

Supply pressure to inlet of unit regulator must be between a minimum of 7” WC and a maximum of 14” WC.

Outlet of regulator must be 5” WC (+) 0.5” WC (-) 0.0” WC.

Maximum pressure drop from Low Flow to Maximum Flow must be less than 0.5” WC

Liquid Propane (LP) Specifications

Supply pressure to inlet of unit regulator must be between a minimum of 11” WC and a maximum of 14”WC.

Outlet of regulator must be 10” WC (+) 0.5” WC (-)0.0” WC.

Maximum pressure drop from Low Flow to Maximum Flow must be less than 0.5” WC.

Connecting Manometer to CG152TF/S

To check pressure on a CG152TF/S the unit must be uninstalled, and the burner pan removed. Once the burner

pan is removed, loosely reassemble burners. Disconnect the Main gas tube from the 9.2k orifice holder and connect

manometer to Main gas tube. Set the burner on High.

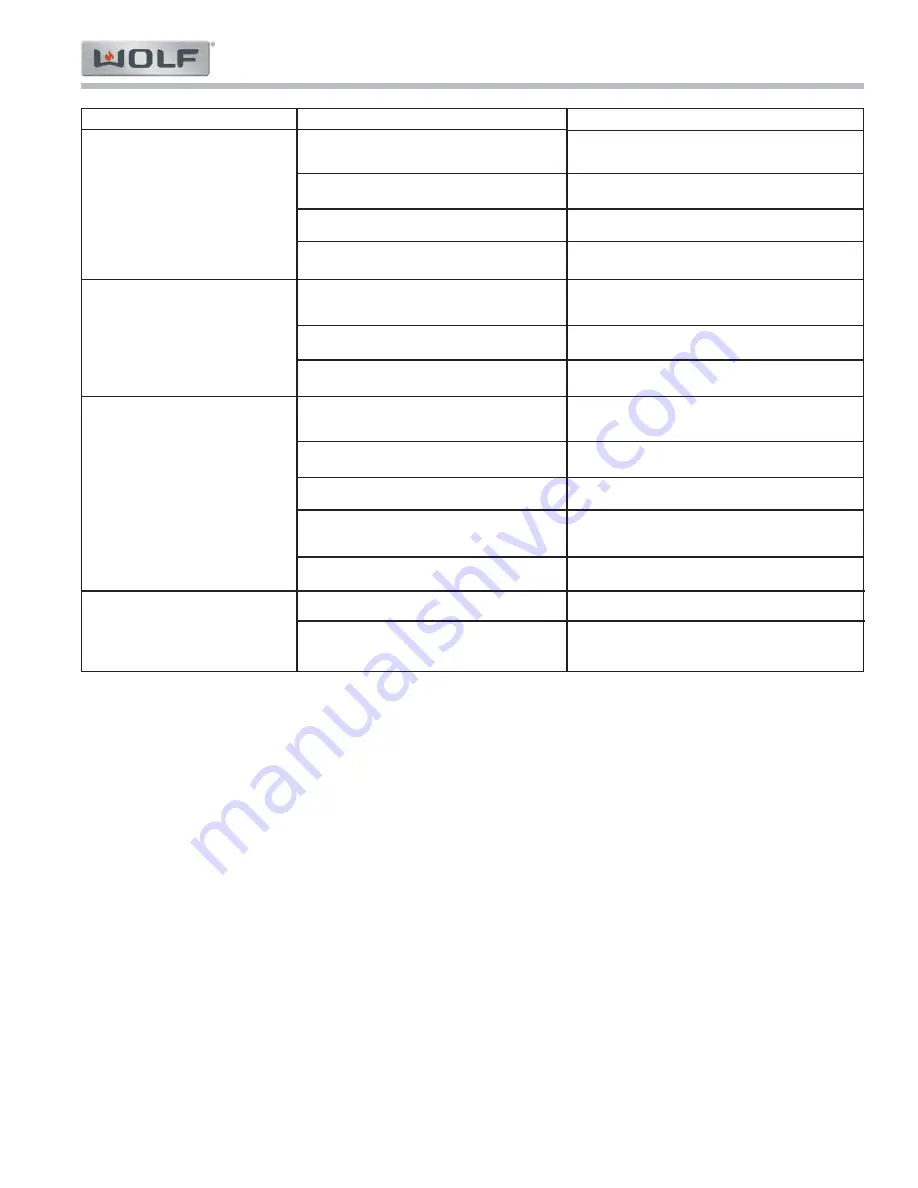

PROBLEM

POSSIBLE CAUSE

TEST / ACTION

D. NO SPARK AT BURNER

ASSEMBLY(S)

E. POPPING

NOISE

AT

BURNER ASSEMBLY DUR-

ING SIMMER MODE

F. FLAME

APPEARANCE

ON

BURNER ASSEMBLY(S)

1. Tall flame

2. Yellow flame

3. Pulsing flames

G. NO KNOB OR LIGHTED

KNOB DISPLAY

No Power (All burners)

Igniter Wire disconnected or damaged

Loose or damaged wire to spark module

Defective 1 point spark module

Burner assembly damaged or dirty with

food debris

Burner assembly cracked or warped

Supply gas impurities

Port holes in burner assembly not to speci-

fication or damaged/dirty

Incorrect gas orifices

Gas pressure

Secondary gas regulator within 10 feet of

unit regulator

Unit regulator damaged

All light displays are dim.

No Display Lights

Check outlet and circuit breaker

Replace igniter wire

Reconnect wire or repair wire harness

Replace 1 point spark module

Replace/clean burner assembly

Replace burner assembly

Especially common with LP gas

Replace/clean burner assembly

Check stamp number on orifices

Check gas pressure using a manometer

Secondary regulator and unit regulator should

be at least 10 feet apart

Check gas pressure using a manometer

Issue with Neutral side of light circuit

Check voltage to Display Light board. Replace

Display Light board.