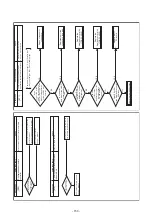

Check code

Location

of

detection

Description

System status

Check code detection

condition(s)

Check items (locations)

<All outdoor units in

corresponding line to be

checked>

• Check connection and

installation of TK1 and TK2

sensors.

• Check resistance

characteristics of TK1 and

TK2 sensors.

• Check for gas or oil leak in

same line.

• Check for refrigerant

problem inside compressor

casing.

• Check SV3D, SV3F valves

for failure.

• Check oil return circuit of

oil separator for clogging.

• Check oil equalizing circuit

for clogging.

Low oil level

protection

I/F

All stop

Operating compressor

detects continuous state of

low oil level for about 2

hours.

H07

H07

—

• Check connection of TK1

sensor connector.

• Check resistance

characteristics of TK1

sensor.

• Check for failure in outdoor

P.C. board (I/F).

Trouble in

temperature

sensor for oil

level detection

I/F

01: TK1 sensor

trouble

02: TK2 sensor

trouble

All stop

Sensor resistance is infinity

or zero (open/short circuit).

H08

H08

• Check installation of TD2

sensor.

• Check connection of TD2

sensor connector and

wiring.

• Check resistance

characteristics of TD2

sensor.

• Check for failure in outdoor

P.C. board (I/F).

TD2 sensor

miswiring

(incomplete

insertion)

I/F

All stop

Discharge temperature of

(TD2) does not increase

despite compressor 2 being

in operation.

H15

H15

—

• Check connection of TK2

sensor connector.

• Check resistance

characteristics of TK2

sensor.

• Check for failure in outdoor

P.C. board (I/F).

All stop

Sensor resistance is infinity

or zero (open/short circuit).

Main

remote

controller

Outdoor 7-segment display

Check

code

Sub-code

• Check installation of TD1

sensor.

• Check connection of TD1

sensor connector and

wiring.

• Check resistance

characteristics of TD1

sensor.

• Check for failure in outdoor

P.C. board (I/F).

TD1 sensor

miswiring

(incomplete

insertion)

I/F

All stop

Discharge temperature of

compressor 1 (TD1) does

not increase despite

compressor being in

operation.

H05

H05

—

• Check service valves to

confirm full opening

(both gas and liquid sides).

• Check outdoor PMVs for

clogging (PMV1, 2, 3).

• Check for failure in SV4

circuits.

• Check for failure in low-

pressure Ps sensor.

• Check indoor filter for

clogging.

• Check valve opening

status of indoor PMV.

• Check refrigerant piping for

clogging.

• Check operation of outdoor

fan (during heating).

• Check for insufficiency in

refrigerant quantity.

Activation of

low-pressure

protection

I/F

All stop

Low-pressure Ps sensor

detects operating pressure

lower than 0.02MPa.

H06

H06

—

- 142 -

Summary of Contents for MMC-UP0151HP-E

Page 41: ...2 2 Ceiling type MMC UP0151HP E TR MMC UP0181HP E TR 41 ...

Page 42: ...MMC UP0241HP E TR MMC UP0271HP E TR 6 4 12 7 42 ...

Page 43: ...MMC UP0361HP E TR MMC UP0481HP E TR MMC UP0561HP E TR 43 ...

Page 58: ...3 WIRING DIAGRAMS 3 1 4 way cassette type MMU UP HP E TR 58 ...

Page 59: ...3 2 Ceiling type MMC UP HP E TR 59 ...

Page 60: ...3 3 Concealed Duct Standard type MMD UP BHP E TR 60 ...

Page 61: ...3 4 Concealed Duct High Static Pressure type MMD UP HP E TR 61 ...

Page 62: ...Concealed Duct High Static Pressure type MMD UP HP E TR 62 ...

Page 63: ...3 5 Concealed Duct High Static Pressure fresh air intake type MMD UP HFP E TR 63 ...

Page 65: ...3 7 High wall type MMK UP HP E TR 65 ...

Page 249: ...MMU UP0361HP E TR MMU UP0481HP E TR MMU UP0561HP E TR 268 267 213 214 249 ...

Page 252: ...12 2 Ceiling type MMC UP0151HP E TR MMC UP0181HP E TR 025 024 252 ...

Page 254: ...MMC UP0241HP E TR MMC UP0271HP E TR 029 028 254 ...

Page 256: ...MMC UP0361HP E TR MMC UP0481HP E TR MMC UP0561HP E TR 051 028 027 256 ...

Page 261: ...MMD UP0151BHP E TR MMD UP0181BHP E TR 240 239 238 233 235 261 ...

Page 263: ...MMD UP0241BHP E TR MMD UP0271BHP E TR MMD UP0301BHP E TR 240 239 238 233 235 263 ...

Page 265: ...MMD UP0361BHP E TR MMD UP0481BHP E TR MMD UP0561BHP E TR 240 239 238 233 235 265 ...