iSort

™

Automated Cell Sorter User Guide

27

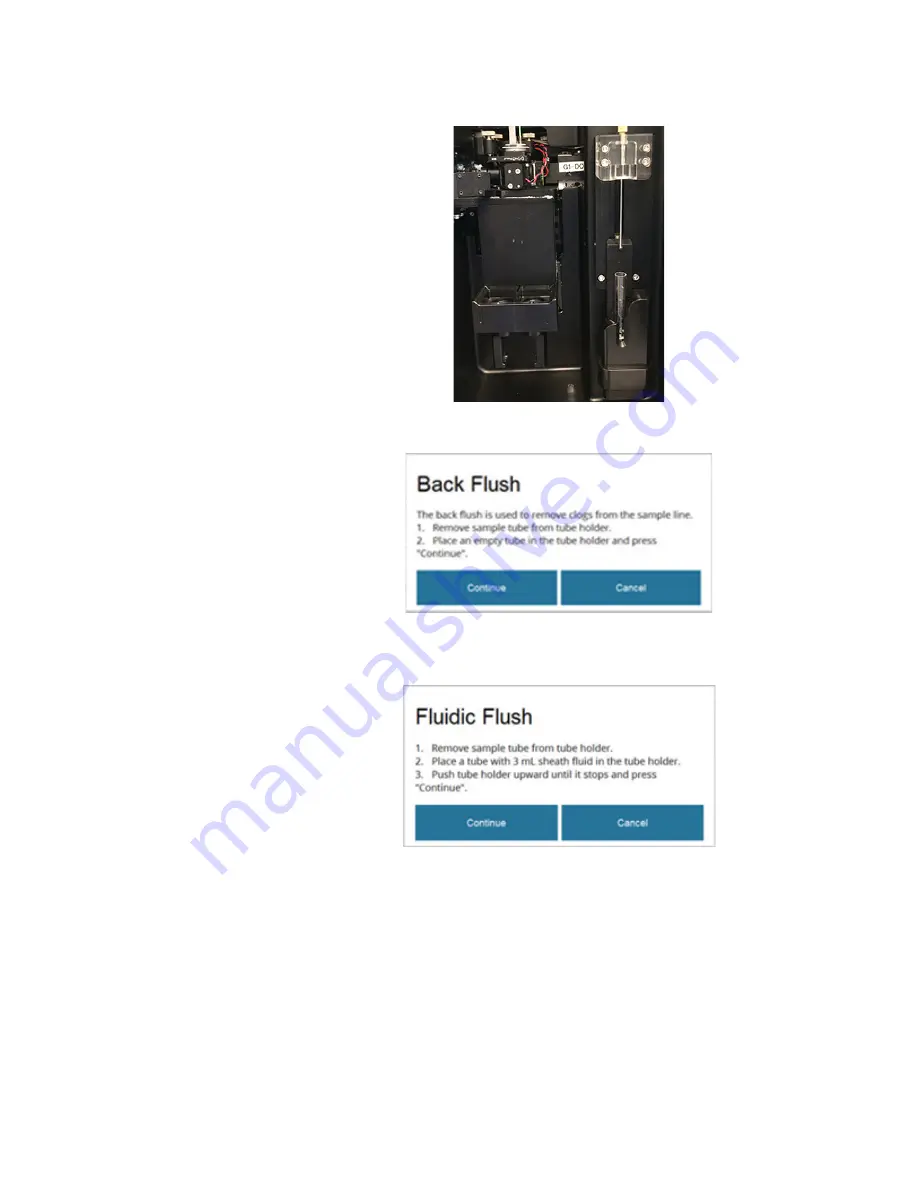

4.

When prompted, place an empty 12 × 75-mm sample tube into the sample tube

holder in the down position.

5.

Press

Continue

to begin the back flush component of the initial cleaning cycle,

which removes clogs from the sample lines.

6.

When prompted, place a fresh 12 × 75-mm sample tube with 3 mL of sheath

fluid into the sample tube holder, then move the sample tube holder to the up

position.

7.

Press

Continue

to begin the fluidic flush component of the initial cleaning

cycle, which washes the sample lines with sheath fluid and is designed to

prevent carryover between samples.

8.

At the completion of the initial cleaning, a prompt will confirm “Initial

Cleaning Complete”. Proceed to Performance Test (page 28) or Analyze and

Sort (page 31).

Summary of Contents for invitrogen iSort Series

Page 120: ...120 iSort Automated Cell Sorter User Guide...

Page 121: ...iSort Automated Cell Sorter User Guide 121...

Page 122: ...122 iSort Automated Cell Sorter User Guide...

Page 123: ...iSort Automated Cell Sorter User Guide 123...

Page 140: ...thermofisher com support thermofisher com askaquestion thermofisher com 19 October 2018...