Maintenance, Service, and Repair

Brakes

Page 8

Typical bleeder

valve

BLEED THE BRAKE SYSTEM

Do not ingest brake fluid or allow contact

with skin or eyes. Always wear protective

clothing and a face shield when working

with or around brake fluid.

SKIN CONTACT

Flush area immediately with water for

several minutes. If a rash or skin irritation

develops, get medical attention

immediately.

EYE CONTACT

Immediately flush the eye with water for

15 minutes and call physician.

INGESTION

Get medical attention immediately.

•

Only use DOT 3 brake fluid from a new

sealed container.

•

DOT 3 brake fluid is corrosive and will

damage paint finishes.

•

Dispose of brake fluid in accordance with

local state and federal regulations.

•

Read and follow all warnings on the

brake fluid container.

NOTE: Hydraulic brakes are optional. Start this

procedure at the wheel furthest from the

master cylinder, then work toward the wheel

closest to the master cylinder.

6. Thoroughly clean the area around the master

cylinder cap and remove the cap.

7. Add brake fluid from a new sealed container to

the master cylinder. Fill to 1/4” from the top of the

master cylinder chamber.

8. The master cylinder fluid level will drop as the

brakes are bled. Periodically check and fill the

master cylinder during this procedure. Do not allow

the fluid level in the master cylinder to drop too

low as this will allow air into the brake lines.

9. Attach a clear hose to the bleeder valve on the

brake cylinder that is to be bled. Route the hose

into a clear container for waste brake fluid.

10. Pump the brake pedal a few times and then press

and hold light pressure to the brake pedal.

11. Open the bleeder valve on the hydraulic brake

body.

12. Depress the foot pedal to the floor and then close

the bleeder valve. Do not release pressure on the

brake pedal until the bleeder valve is closed.

13. Slowly release the foot pedal, allowing it to return

to its released position.

NOTE: Check and fill the master cylinder frequently

during the bleeding process. Do not allow the

fluid level in the master cylinder to drop low

enough to allow air to enter the brake lines.

If air enters the brake lines during the bleeding

process, then you will have to start again from

the beginning.

14. Repeat the above steps until you are sure that all

of the air is expelled from the brake line. Any air

bubbles that can be seen in the clear hose attached

to the bleeder is an indication that there is still air

in the brake lines.

15. Repeat this process with each of the other wheels.

NOTE: When finished, top off the master cylinder

with fluid. See

Check Master Cylinder

Fluid

for information on filling the master

cylinder.

16. Reconnect the main positive and negative cables

at the batteries.

17. Remove the blocks from behind the wheels.

18. Release the park brake and test drive the vehicle.

Summary of Contents for B 1-50

Page 2: ......

Page 6: ...TAYLOR DUNN ...

Page 14: ...Model B 1 00 ...

Page 30: ...TAYLOR DUNN ...

Page 36: ...TAYLOR DUNN ...

Page 52: ...TAYLOR DUNN ...

Page 66: ...Maintenance Service and Repair Steering Page 14 Exploded View of Steering Gear ...

Page 90: ...TAYLOR DUNN ...

Page 124: ...TAYLOR DUNN ...

Page 130: ...TAYLOR DUNN ...

Page 161: ...Wire Diagrams ...

Page 194: ...Illustrated Parts PARTS PAGE 10 Front Suspension 4 3 2 1 5 10 6 8 9 7 11 12 ...

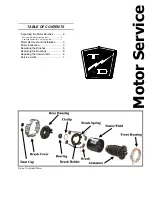

Page 202: ...Illustrated Parts PARTS PAGE 18 Motor 2 3 5 6 4 7 8 1 9 10 Armature 9 ...

Page 206: ...Illustrated Parts PARTS PAGE 22 Wheels and Tires Ref wheel hub 1 2 5 assembly 4 3 6 7 8 9 ...

Page 208: ...Illustrated Parts PARTS PAGE 24 Instrument Panel dash ...

Page 217: ...Illustrated Parts PARTS PAGE 33 This page intentionaly left blank ...

Page 220: ...Illustrated Parts PARTS PAGE 36 Seat Cushions Deck and Lights B 1 50 ...

Page 222: ...Illustrated Parts PARTS PAGE 38 Seat Cushions Deck and Lights MX 1600 ...

Page 224: ...Illustrated Parts PARTS PAGE 40 Decals B 1 50 VIEW FROM INSIDE OF COWL 1 2 3 4 5 6 7 8 9 ...

Page 230: ...Illustrated Parts PARTS PAGE 46 Stake Sides B 1 50 1 2 3 4 5 6 7 8 ...