(Dec., 2013)

STULZ CyberRow Chilled Water Series Installation, Operation & Maintenance Manual

1-6

maintenance is performed. The handle of the switch

may be locked in the “Off” position to prevent

unintended operation.

1.5.2 Circuit Breakers/Motor Start Protectors

CyberRow units incorporate state of the art component

protection with the use of motor start protectors and

circuit breakers. If an overload occurs the switches

must be manually re-set after the overload condition is

cleared.

1.5.3 Coil(s)

Cooling coils are aluminum fi nned/copper tube

construction. The coils are leak tested and cleaned

before installation by the factory. Condensate drain

pans are provided to collect water condensed by the

coils. The drain pans are emptied by a condensate

pump that directs the water to a pipe stub located

either at the top or the bottom of the A/C unit

depending on the piping confi guration (see Sections

2.7.1.1 and 2.7.1.2).

A fl oat switch is placed in the lower condensate pan

to detect if the water level rises. If the condensate pan

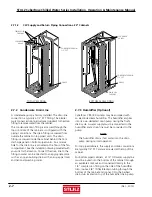

Figure 2- Typical Internal Layout- CRS-180-C

NOTE:

1. CABINET ACCESS PANELS REMOVED TO SHOW INTERNAL PARTS.

DRAIN PANS

LEVEL ADJUSTMENT

SCREW (4)

CONDENSATE

PUMP

EC FAN (3)

HINGED ELECTRIC BOX

COVER

DISCONNECT

SWITCH

COIL

AIR FILTERS

SUPPLY / RETURN PIPE

TRANSITION PLATE

T/H SENSOR

CASTER HOUSING

(4)

TEMPERATURE SENSORS

(HIDDEN FROM VIEW)

CW VALVE

HUMIDIFIER

HUMIDIFIER DRAIN

PUMP

FLOAT SWITCH

fails to drain, the fl oat switch signals the controller to

annunciate an alarm.

1.5.4 Condensate Pump

A condensate pump is factory installed in the lower

drain pan. The pump automatically eliminates

condensate water from the drain pan. The pump has an

internal fl oat switch which turns the pump on and off

based on the water level.

1.5.5 EC Fans

The unit is equipped with three high effi ciency,

Electronically Commutated (EC) fans. EC fans utilize a

brushless motor equipped with permanent magnets

and permanently lubricated ball bearings. The fan

impellers are backward curved and attached to the

rotor casing. The fan is balanced and aerodynamically

optimized to minimize vibration.

The fans do not utilize drive belts. Fan speed is variable

via a 0 to 10 VDC signal from the system controller.

The fan motor is equipped with integral electronics and

does not require the addition of secondary electronics

such as thermal protection, inverters or fi lters. The fan