STULZ CyberRow Chilled Water Series Installation, Operation & Maintenance Manual

(Dec., 2013)

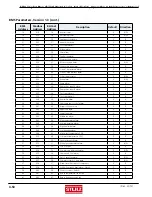

Figure 17- Cartridge Filters

Screws (4)

End Cap

Rear Access

Panel

5-2

5.1.1.2 Cartridge

Filters

Disposable pleated cartridge fi lters are

held in place by an end cap in the bottom

of the rear access panel. Lay the access

panel down on a piece of cardboard or

padded surface. Remove the four screws

holding the end cap in place. Remove the

end cap and slide the old fi lters out of

the tray as shown in Figure 17. Slide the

new fi lters into the tray and replace the

end cap. Ensure the four screws are fully

tightened.

Inspect the water level switch and ensure that the

fl oat works freely. Wipe the fl oat with a wet cloth and

detergent to remove dirt. Check that the discharge line

is open and water can pass through it freely.

5.1.6 Humidifi er

The steam cylinder has a limited lifetime and must be

replaced periodically. Because water conditions and

humidifi er usage rates vary greatly, it is diffi cult to

establish intervals for changing the cylinder. Individual

maintenance schedules must be determined for each

location, based upon periodic examination of the hu-

midifi er. A yellow LED on the humidifi er control panel

will fl ash four times in a repeating pattern when the

cylinder requires replacement.

NOTE

The yellow LED may illuminate during initial start-

up but it doesn’t necessarily mean the cylinder

needs to be replaced.

Refer to Section 5.3.2.1 and the humidifi er operator’s

manual supplied separately for detailed instructions on

changing the cylinder.

5.1.6.1 Humidifi er Drain Pump

The humidifi er drain pump (located beneath the

humidifi er) should be inspected semi-annually and

cleaned. The same maintenance procedures, as detailed

in Section 5.1.5, should be performed to properly

maintain the humidifi er drain pump.

5.1.2 EC Fans

Periodic checks of the EC fans should include checking

the wiring, fan motor mounts, housing and impeller

wheel. Ensure all electrical connections are tight. Check

that all mounting fasteners are secure and the impeller

wheel is tightly mounted. The impeller blades must be

kept free of debris.

5.1.3 Coil

The coil should be inspected semi-annually and cleaned

as required, following standard coil cleaning practices.

Using a brush, clean the coil fi ns of all debris that will

inhibit airfl ow. This can also be done with compressed

air or with a commercial coil cleaner. Check for bent

or damaged coil fi ns and repair as necessary. Check all

CW lines for vibration isolation and provide supports as

necessary. Check all piping for signs of leaks.

5.1.4 Drain Pans

To ensure proper drainage, inspect the drain pans

regularly. Make sure the drain pan outlets are always

free of debris so they empty readily and ensure the

drain pans do not leak.

WARNING

Do not use chloride based water conditioning

additives in the condensate drain pans. This will

cause corrosion to occur on the coil fi ns.

5.1.5 Condensate Pump

The condensate pump should be inspected semi-annual-

ly and cleaned. It will be necessary to remove the pump

as described in Section 5.3.2.4.