STULZ CyberRow Chilled Water Series Installation, Operation & Maintenance Manual

(Dec., 2013)

2-6

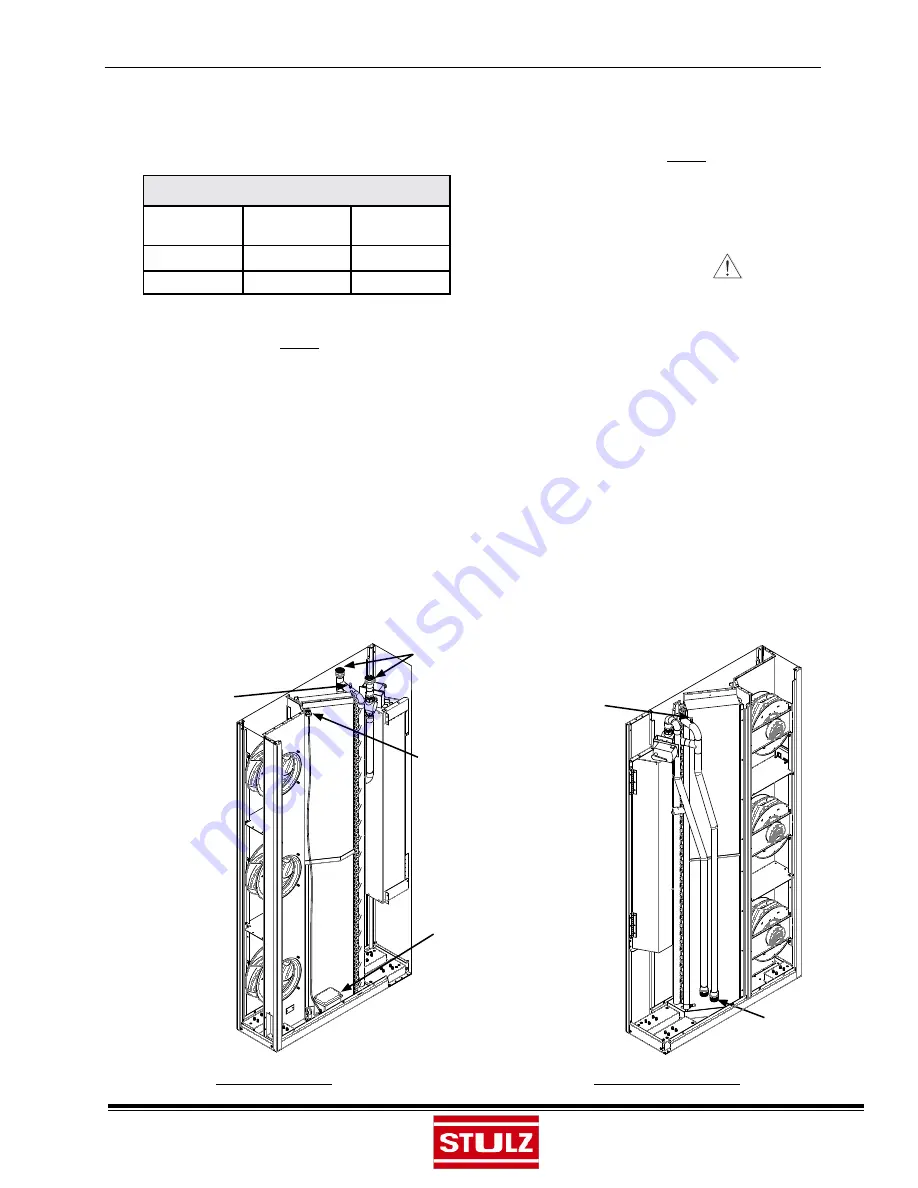

For pipe connection sizes, refer to the following table:

PIPE CONNECTION SIZES

Chilled Water Condensate

Model #

Inlet/Outlet Drain

CRS-090-C

1 1/4”

1/2”

CRS-180-C

1 1/2”

1/2”

NOTE

Use standard refrigeration practices for piping,

leak testing and fi lling the chilled water circuit.

The piping should be isolated by the use of vibration

isolating supports. Provide supports (clamps or hangers)

as necessary every 5 to 10 feet along piping runs to

minimize vibration and noise transmission. To reduce

vibration transmission and prevent pipe damage, seal

openings in walls using a soft fl exible material to pack

around the piping. After the piping is installed, seal the

gaps between the pipes and the cabinet entrance holes

so air won’t leak around the pipes.

NOTE

Chilled water lines should be insulated to prevent

condensation from forming on the pipes if

ambient dew point temperatures are higher than

the fl uid temperatures.

CAUTION

After the interconnecting piping is installed, the

entire piping circuit must be thoroughly fl ushed

prior to operating the system.

If newly installed CW supply and return piping is used,

it is recommended that the piping system be cleaned

prior to connecting it to the unit.

If solvents/cleaning

solutions are used, ensure they are completely

fl ushed from the piping before connecting it to

the unit.

Failure to do so could result in equipment

problems.

2.7.1.1 CW Supply and Return Piping Connections- 12” Cabinets

FEMALE PIPE

THREADS

CONDENSATE DRAIN-

1/2” FPT

SCHRADER

VALVE

PUMP

SCHRADER

VALVE

MALE PIPE THREADS

TOP

ACCESS

PIPING

BOTTOM

ACCESS

PIPING