(Dec., 2013)

STULZ CyberRow Chilled Water Series Installation, Operation & Maintenance Manual

2-5

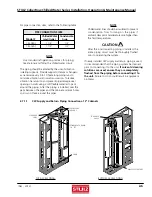

2.7 CW

Cooling

The system utilizes a chilled water source to provide coolant to the cooling coil in the A/C unit. When the hot aisle

air temperature rises to the CW cut-in setpoint plus dead band, the controller opens the modulating CW control

valve proportionally to the demand for cooling (see Figure 5).

CHILLED WATER COIL

SUPPLY

INLET

RETURN

OUTLET

FIELD PIPING BY INSTALLER

INTERCONNECTING

SCHRADER VALVE

3-WAY

MIXING VALVE

OPTIONAL

A

AB

B

FIELD PIPING BY INSTALLER

INTERCONNECTING

A

AB

2-WAY

MIXING VALVE

STANDARD

Figure 5- Typical CW Piping Diagram

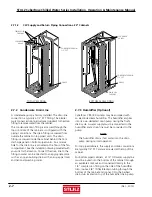

2.7.1 Piping Connections

CAUTION

The cooling coil (and associated piping circuits)

are

pressurized with dry nitrogen (up to 100

psi)

and sealed when they leave the factory.

Before installing the interconnecting piping,

release the pressure via an available stem valve

or schrader valve prior to uncapping the pipes.

Supply and return lines are routed to either the top or

bottom of the cabinet as specifi ed when the CyberRow

system is ordered (see Sections 2.7.1.1 and 2.7.1.2).

On units that are piped from the top, the chilled water

supply and return connections are made outside the

cabinet. On units that are piped from the bottom, the

chilled water supply and return connections are made

inside the cabinet. Pipe connections are threaded NPT

connections. The pipes are labeled; i.e. “Supply”,

“Return”. When making the connections, a tefl on tape

thread sealant is recommended to minimize internal

fouling of the piping.

Field piping is not necessarily the same size as the units’

pipe connections. Piping should be sized to match

the system pressure drop and fl ow capacity, and may

require reducing fi ttings to match the connection size

on the air conditioner. An air vent and several schrader

valves are installed in the precision A/C unit piping. It

is recommended to provide manual shut-off valves for

both the supply and return for isolating the unit when

performing routine maintenance or repairs. Refer to

the piping diagram supplied with your unit.

NOTE

A 60-mesh strainer should be installed in

the supply pipe. Ensure the strainer is read-

ily accessible for servicing or replacement.

In situations where scaling could be heavy, or where

biological growth will be present, a closed loop system

is recommended. Untreated water in the unit cooling

coils may cause, over a period of time, a loss of heat

exchange capacity due to a mineral deposit build-up

inside the coil. Only a qualifi ed service mechanic should

clean dirty coils.