Advanced commissioning

6.13 Setpoint calculation

Converter with the control units CU240D-2

Operating Instructions, 04/2018, FW V4.9 SP10, A5E34262100B AF

175

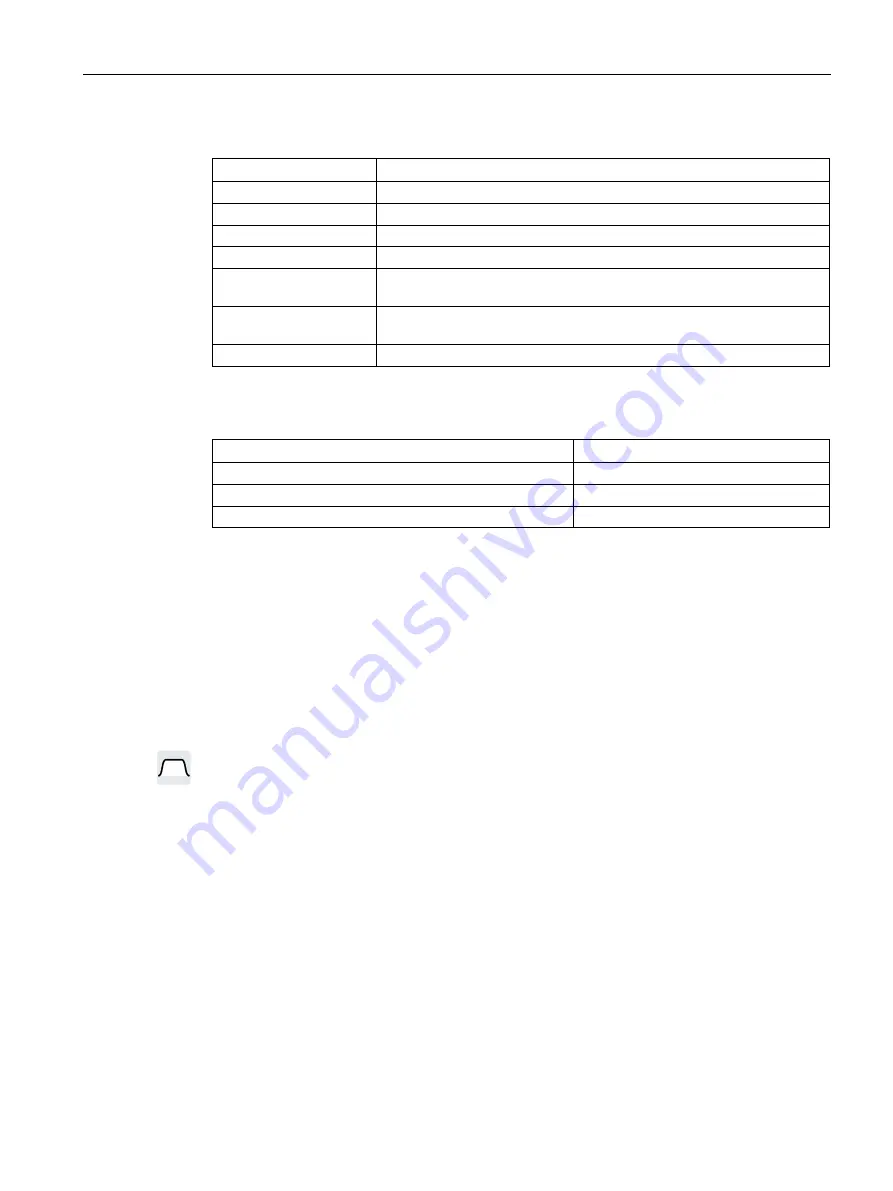

Table 6- 21 Settings for the application example

Parameter

Description

p1001 = 300.000

Fixed speed setpoint 1 [rpm]

p1002 = 2000.000

Fixed speed setpoint 2 [rpm]

p0840 = 722.0

ON/OFF1: Switches on the motor with digital input 0

p1070 = 1024

Main setpoint: Interconnects the main setpoint with fixed speed setpoint.

p1020 = 722.0

Fixed speed setpoint selection bit 0: Interconnects fixed speed setpoint 1

with digital input 0 (DI 0).

p1021 = 722.1

Fixed speed setpoint selection bit 1: Interconnects fixed speed setpoint 2

with digital input 1 (DI 1).

p1016 = 1

Fixed speed setpoint mode: Directly selects fixed speed setpoints.

Table 6- 22 Resulting fixed speed setpoints for the application example

Fixed speed setpoint selected via

Resulting setpoint

DI 0 = 0

Motor stops

DI 0 = 1 and DI 1 = 0

300 rpm

DI 0 = 1 and DI 1 = 1

2300 rpm

6.13

Setpoint calculation

6.13.1

Overview

Overview

Setpoint processing influences the setpoint using the following functions:

●

"Invert" inverts the motor direction of rotation.

●

The "Inhibit direction of rotation" function prevents the motor from rotating in the incorrect

direction; this function can make sense for conveyor belts, extruders, pumps and fans, for

example.

●

The "Skip frequency bands" prevent the motor from being continuously operated within

these skip bands. This function avoids mechanical resonance effects by only permitting

the motor to operate briefly at specific speeds.