MX-2300/2700 N/G SIMULATION 7 – 129

Place the printed 48-patch pattern on the glass table, and

press [FACTORY] or [SERVICE] button to select the process

mode.

4)

Press [EXECUTE] button. [EXECUTE] button is highlighted

and the set 48-patch pattern is scanned.

Check to insure that there is A3 paper in the paper feed tray. If

paper is insufficient, supply it.

5)

After completion of patch scan, the 16-patch self-printing is

automatically started.

6)

After completion of self-printing, the display is shifted to the

registration process standby screen.

When [REPEAT] button is pressed, the correction value is not

saved and the display returns to the initial screen.

When [OK] button is pressed, the correction value is saved to

EEPROM and RAM and the half-tone process control refer-

ence value registration process is started.

7)

The display is shifted to the reference value registration pro-

cess 1 completion screen. The reference value registration

process 2 (Black) is automatically started.

8)

When the reference value registration process 2 (Black) is

completed, the following message is displayed. (Each mes-

sage is automatically shifted.)

BLACK: 2ND STEP BLACK END

CYAN: 2ND STEP CYAN END

MAGENTA: 2ND STEP MAGENTA END

YELLOW: 2ND STEP YELLOW END

* When the process control is executed second time, "2nd" is

displayed.

9)

All the registration processes are completed.

* When [CA], [SYSTEM STTINGS], or [EXECUTE] button is

pressed during self-printing, the operation is interrupted.

[Cancel of execution during operation]

• To cancel or resume, press [EXECUTE] button.

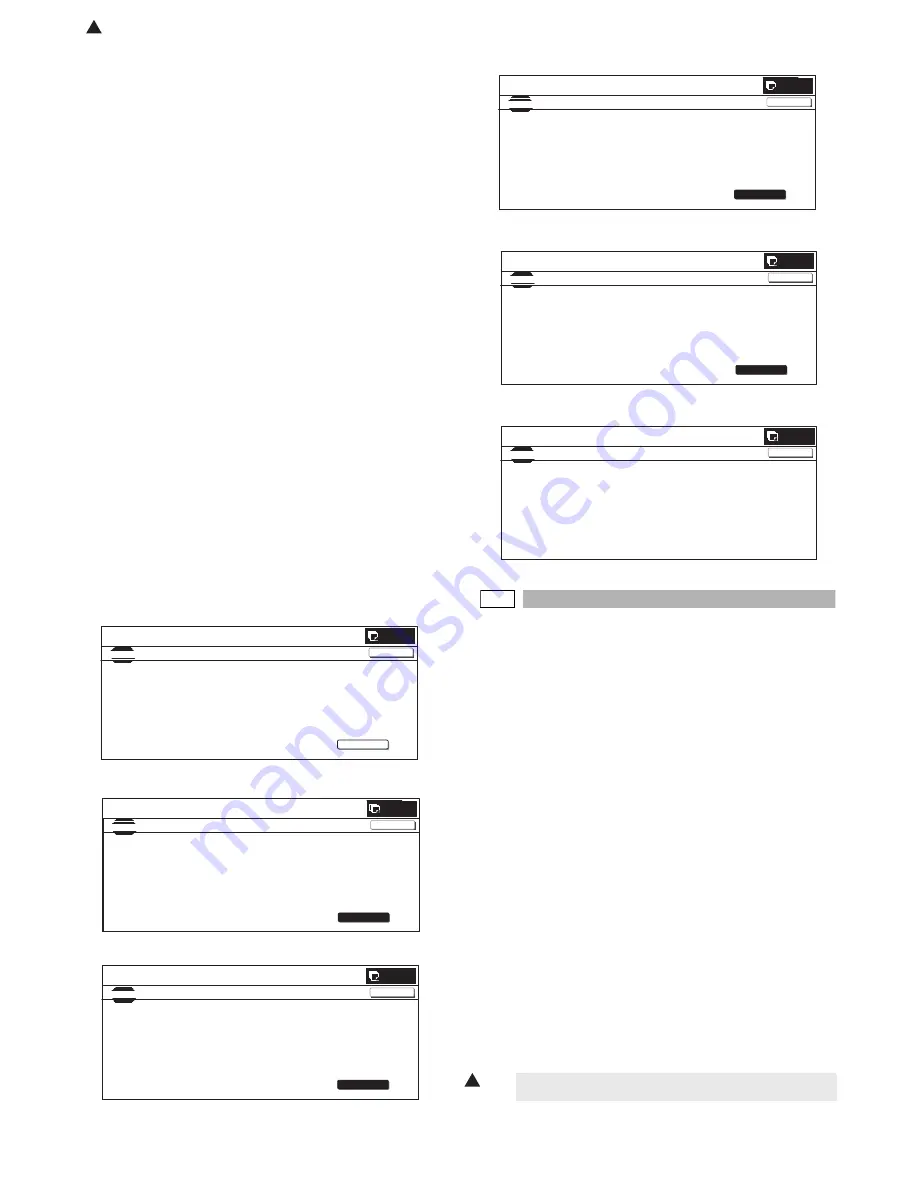

[Initial Screen]

(During the 48-patch printing)

(The output patch scan screen)

(During the 16-patch self-printing)

(The half-tone process control reference value registration screen)

(All processes complete screen)

67-25

Purpose

: Adjustment

Function (Purpose)

: Used to set the manual correction of the

printer engine color balance.

Section

: Printer

Item

: Adjustment

Operation/Procedure

1)

Use [K][C][M][Y] button to select a color. (The selected button

is highlighted.)

Select the set item with [

↑

] and [

↓

] buttons.

The highlighted section of the set value is switched and dis-

played on the set setting area.

* If there is any item over [

↑

], an active display is made and

item is shifted.

If there is no item over [

↑

], the display grays out and the

operation is invalid.

If there is any item under [

↓

], an active display is made and

item is shifted.

If there is no item over [

↓

], the display grays out and the

operation is invalid.

2)

Enter the set value with 10-key.

When [OK] button is pressed, the set value is saved to

EEPROM and RAM.

* Press [C] key to clear the entered values.

* Use [

U

] [

V

] buttons to change the set values collectively.

When the set value is not the upper limit (lower limit) value,

each item value is increased (decreased) by one. If the set

value is the upper limit (lower limit) value, it is not changed.

SIMULATION

NO.67-24

TEST

PRINTER ENGINE HALFTONE AUTO ADJUSTMENT MODE

EXECUTE

0

CLOSE

PRESS [EXECUTE] TO PROCON EXECUTION AND PRINT THE TEST PATCH.

(PLEASE USE SPECIFIED TYPE OF A3 OR 11”

17” SIZE PAPER

FOR THIS ADJUSTMENT)

SIMULATION NO.67-24

TEST

PRINTER ENGINE HALFTONE AUTO ADJUSTMENT MODE

0

CLOSE

TEST PATCH PRINTING IN PROGRESS...

EXECUTE

SIMULATION NO.67-24

TEST

PRINTER

ENGINE

HALFTONE

AUTO

ADJUSTMENT

MODE

0

CLOSE

PLEASE

WAIT.

NOW READING THE PRINTED TEST PATCH

EXECUTE

SIMULATION NO.67-24

TEST

PRINTER ENGINE HALFTONE AUTO ADJUSTMENT MODE

0

CLOSE

ADJUSTED PATCH PRINTING IN PROGRESS.

EXECUTE

SIMULATION NO.67-24

TEST

PRINTER

ENGINE

HALFTONE

AUTO

ADJUSTMENT

MODE

0

CLOSE

PLEASE

WAIT.

NOW

REGISTERING

THE

NEW

TARGET

OF

HALFTONE

PROCON.

EXECUTE

SIMULATION NO.67-24

TEST

PRINTER

ENGINE

HALFTONE

AUTO

ADJUSTMENT

MODE

0

CLOSE

COMPLETED

THIS

PROCEDURE.

PLEASE

QUIT

THIS

MODE.

1

To change the color balance, change each color set value as

below.

: Dec. 15 2005

1