MX-2300/2700 N/G ADJUSTMENTS 6 – 60

2)

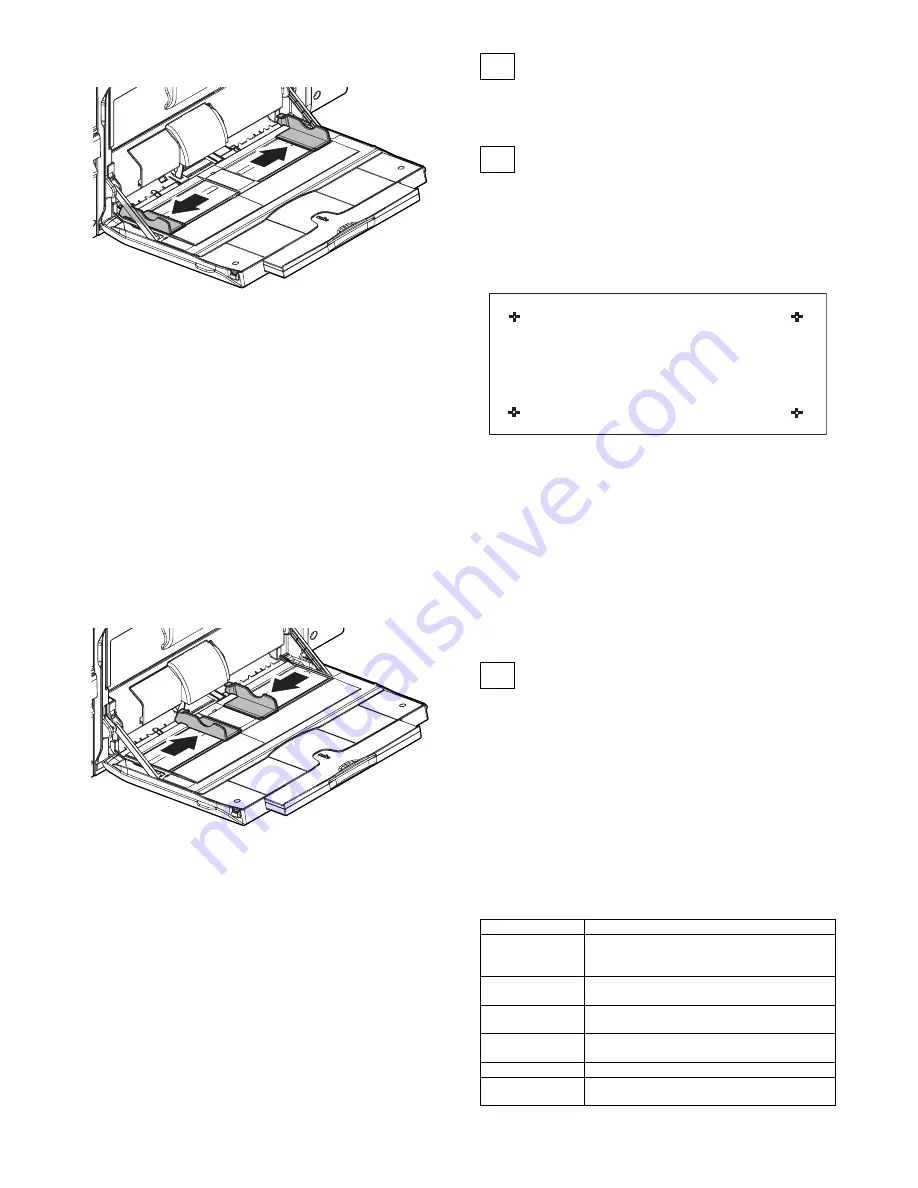

Set the manual paper feed guide to the maximum width posi-

tion.

3)

Press [EXECUTE] key.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

The maximum width position detection level of the manual

paper feed guide is recognized.

4)

Set the manual paper feed guide to the A4 size.

5)

Press [EXECUTE] key.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

The A4 size width position detection level of the manual paper

feed guide is recognized.

6)

Set the manual paper feed guide to the A4R size width.

7)

Press [EXECUTE] key.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

The A4R size width position detection level of the manual

paper feed guide is recognized.

8)

Set the manual paper feed guide to the minimum width posi-

tion.

9)

Press [EXECUTE] key.

[EXECUTE] key is highlighted. Then it returns to the normal

display.

The minimum width position detection level of the manual

paper feed guide is recognized.

If the above operation is not completed normally, "ERROR"

display is highlighted.

When the operation is completed normally, the above data are

saved to the memory and "COMPLETE" is displayed.

25

RSPF tray paper size (width) sensor

adjustment (Refer to the MX-RPX1

SM.)

26

Touch panel coordinate setting

This adjustment is required in the following cases:

* When the operation panel is replaced.

When a U2 trouble occurs.

When the scanner control PWB is replaced.

When the EEPROM on the scanner control PWB is replaced.

1)

Enter the SIM65-1 mode.

2)

Precisely press the cross mark points (4 positions).

When the cross mark is pressed precisely, a buzzer sounds

and the display is reversed. When all the four points are

pressed and the touch panel adjustment is completed, the dis-

play returns to the simulation sub number entry screen.

In case of an error, the display returns to the entry screen

again.

Check to confirm that there is no shift between the display

frame and the detection position when the touch panel is

pressed.

* When pressing the touch panel, never use a sharp tip (such

as a needle or a pin).

27

Image loss, void area, image off-cen-

ter, image magnification ratio auto

adjustment with SIM50-28

The following adjustment items can be executed automatically with

SIM50-28.

* ADJ 8 Print image magnification ratio adjustment (Main scanning

direction) (Print engine section)

* ADJ 9 Image off-center adjustment (Print engine section)

* ADJ 14/15 Scan image magnification ratio adjustment

* ADJ 16 Scan image off-center adjustment

* ADJ 17 Print area (void area) adjustment (Print engine section)

* ADJ 18 Copy image position, image loss adjustment

(Menu in SIM50-28 mode)

Display/Item

Content

OC ADJ

Image loss off-center sub scanning direction image

magnification ratio adjustment (Document table

mode)

BK-MAG ADJ

Main scanning direction image magnification ratio

adjustment

SPF ADJ

Image loss off-center sub scanning direction image

magnification ratio adjustment (RSPF mode)

SETUP/PRINT ADJ

Print lead edge adjustment, image off-center (each

paper feed tray, duplex mode) adjustment

RESULT

Adjustment result display

DATA

Display of data used when an adjustment is

executed