Page 235

STAT

IM 2000/2000S

Service Guide

96-106775 Rev 5.0

11. Steam Generator, Check Valve, Thermal Fuse and Pressure Relief Valve

STAT

IM

5000/5000S/5000 G4 Service Guide

Replacing the Thermal Fuse on the Aluminium Steam Generator

(for all models)

Determine which configuration is being serviced and use the appropriate parts to service the unit.

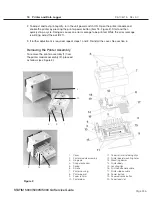

To replace the thermal fuse proceed as follows (refer to Figure 9):

1. Connect the terminal of the appropriate thermal fuse (5 for type A - single) or (8 for type B/C -

double) to the lower power terminal on the steam generator (1 for type A/B) or (10 for type C).

2.

a. For Type A configuration, replace the steam generator bracket (2) with a modified steam

generator bracket (9). Route the wire from the fuse assembly (5) between the standoffs

(7) and the standoffs on the modified steam generator bracket. The fuse must be placed

exactly between the standoffs. Attach the steam generator bracket to the steam generator

(1) using the small screw (4). Do not pinch or crush the wire between components. Ensure

that the screw is tightened securely.

b. For Type B configuration, route the wire from the fuse assembly (8) between the standoffs

(7) on the bottom of the steam generator (1) and the standoffs on the modified steam

generator bracket (9). The fuse must be placed exactly between the standoffs. Attach the

steam generator bracket to the steam generator (1) using the small screw (4). Do not pinch

or crush the wire between components. Ensure that the screw is tightened securely.

c. For Type C configuration, route the wire from the fuse assembly (8) between the two sets

of standoffs (7) on the bottom of the modified steam generator (10).

The fuse must be placed exactly between the standoffs. Attach the steam generator

bracket (2) to the steam generator using the small screw (4). Do not pinch or crush the wire

between components. Ensure that the screw is tightened securely.

NOTE: For the remainder of the procedure, refer to Figure 11 and proceed as follows.

3. Carefully return and attach the steam generator assembly to the chassis using two screws

(14). Start the screws into the tapped hole but do not tighten the screws. Be careful not to

stress the thermocouple leads. (Min. bend radius - 3/16 inch / 5 mm).

4. Connect the compression nut (12) holding the steam generator outlet tube (10) to the steam

generator outlet fitting (13) and the compression nut (9) holding the steam generator outlet

tube (10) to the probe bracket inlet fitting (11). Tighten finger tight.

5. Connect the compression nut (7) holding the Teflon™ pump tube (8) to the top of the steam

generator. Tighten finger tight, then continue to tighten the nut using a 3/8-inch wrench. Do

not overtighten.

6. Tighten the two screws (14) that attach the steam generator assembly to the chassis.

7. Using a wrench, tighten the compression nut holding the steam generator outlet tube to the

steam generator outlet fitting and also the compression nut holding the steam generator outlet

tube to the probe bracket fitting.

8. Route the black wire (4) from the fuse assembly and connect the wire to Controller Board

connector J1-3. Connect the white wire (12) to the steam generator electrical terminal (19).

9. Bundle the loose wires together in the wiring harness and secure using nylon cable ties every

2-3 inches.

10. Reinstall the compressor tube (6) onto the check valve inlet (3) and secure the tube to the

valve with a high temperature rated cable tie (1).