Page 197

STAT

IM 2000/2000S

Service Guide

96-106775 Rev 5.0

9. Solenoid Valve and Pressure Transducer

STAT

IM

5000/5000S/5000 G4 Service Guide

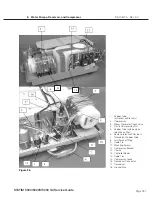

7. Bundle the wires together and secure them using cable ties every 2 to 3 inches.

8. Test the solenoid by activating the solenoid switch on the Control box. Note: the cassette

must be removed or unseated so that the microswitch is not active as the solenoid will be

permanently energized and will not be affected by the control box switch/button.

9. A dielectric strength test (Hi-Pot) and a protective bonding impedance test (ground continuity)

MUST be performed on the unit.

NOTE:

These tests must be performed on the STAT

im

again once the work is completed and

the cover has been returned to the unit.

10. Run a sterilization cycle and observe all fittings and tubes for leaks. Check LCD read-outs for

messages indicating cycle status.

Pressure Transducer

Note:

only ‘S’ type (eu) STAT

IM

models have pressure transducers.

STAT

im

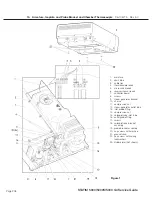

5000S units use a pressure transducer to measure the steam pressure in the unit. The

transducer is attached to a bracket located in the right rear corner of the unit. Transducer wires

are routed along the top of the armature to a Pressure Interface Board attached to the P2 printer

connector on the controller board, (Revision 2.x, 5.x and 6.x controller boards), or direct to the

main PCB (Revision 7.x controller boards).

Identifying and checking the Pressure Transducer

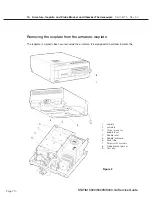

Note that there are two types of pressure transducer used on STAT

im

S models, a 0 - 60 p.s.i.

transducer on models up to approximately 2004 and a 0 - 68 p.s.i. transducer on models from

2004 on. The input voltage is the same for both types, but the output voltage is different so

the

two types are not interchangeable

.

Pressure transducer

Figure 4