Page 186

STAT

IM 2000/2000S

Service Guide

96-106775 Rev 5.0

8. Water Pumps, Reservoir, and Compressor

Removing and Reinstalling the Medo compressor

Removing the Medo Compressor

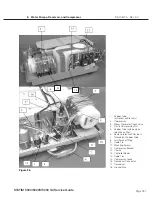

To remove the compressor, follow these steps (see Figure 26):

1. Turn the power switch OFF, and unplug the unit.

With the cylindrical air filter only:

2A. Locate the silicone rubber tube (5) which extends from the compressor (2) to the steam

generator check valve (3). Disconnect the compression nut (4) securing the tube to the

compressor and remove the tube from the fitting.

With the additional bacteria-retentive filter:

2B. Locate the rubber tube (5) which extends from the compressor (2) to the input side of the

bacteria-retentive filter (6). Disconnect the compression nut (4) securing the tube to the

compressor and remove the tube from the fitting.

3. Remove the transparent rubber tube (7) which extends from the compressor intake fitting to the

air fitting (8). Cut the cable tie (9) securing the tube to the compressor and remove the tube from

the fitting.

4. Remove the four screws (10) that attach the compressor bracket (11) to the chassis (12). Retain

the screws. Some compressor brackets may appear slightly different then the bracket you are

servicing. Use the bracket that accompanies the replacement compressor.

5. Disconnect the leads from controller board (13) terminal block positions J1-9 LINE and J1-10

NEUTRAL, and carefully cut the cable ties (14) securing the compressor leads (15).

6. If present, remove the pressure transducer. See Chapter 9, Pressure Transducer.

7. Disconnect the ground wire (18) from the compressor body and remove the compressor from

the unit.

Reinstalling the Medo Compressor

SciCan recommends that the check valve be replaced when the compressor is replaced.

See Chapter 11, Steam Generator Removal, Cleaning and Replacement, the Steam Generator

Check Valve.

To replace the compressor, follow these steps (see Figure 26):

1. Connect the ground wire (18) to the compressor body.

2. Position the compressor / bracket assembly (11) in the chassis (12). Route the compressor

leads (15) with the bundle of wires leading to the controller board (13). Connect the lead to

controller board terminal block position J1 - 9 LINE and the wire to terminal block position

J1-10 NEUTRAL.

3. Bundle the wires together and secure them using nylon cable ties (14) every 2 - 3 inches.

4. Reinstall the four screws (10) retained during disassembly. Do not crush wires or tubes.

5. Reinstall the pressure transducer (17), if present. See, Pressure Transducer.

6. Connect the transparent rubber tube (7) which extends from the compressor intake fitting to the

air filter fitting (8). Secure the tube using a nylon cable tie (9).

With the cylindrical air filter only:

7A. Connect the rubber tube (5) which extends from the top of the compressor (2) to the steam

generator check valve (3). Secure the tube using the plastic compression nut (4).

STAT

IM

5000/5000S/5000 G4 Service Guide