4-8

4-8-1. Move commands for each interpolation

Interpolation types applicable to welding robots and to handling robots

Welding robots

Handling robots

Move command

Interpolation type

Move command

Interpolation type

MOVEP

PTP

MOVEP

PTP

MOVEL

Linear

MOVEL

Linear

MOVEC

Circular

MOVEC

Circular

MOVELW

Linear weaving

MOVECW

Circular weaving

Move command for amplitude points of weaving interpolations is “WEAVEP”.

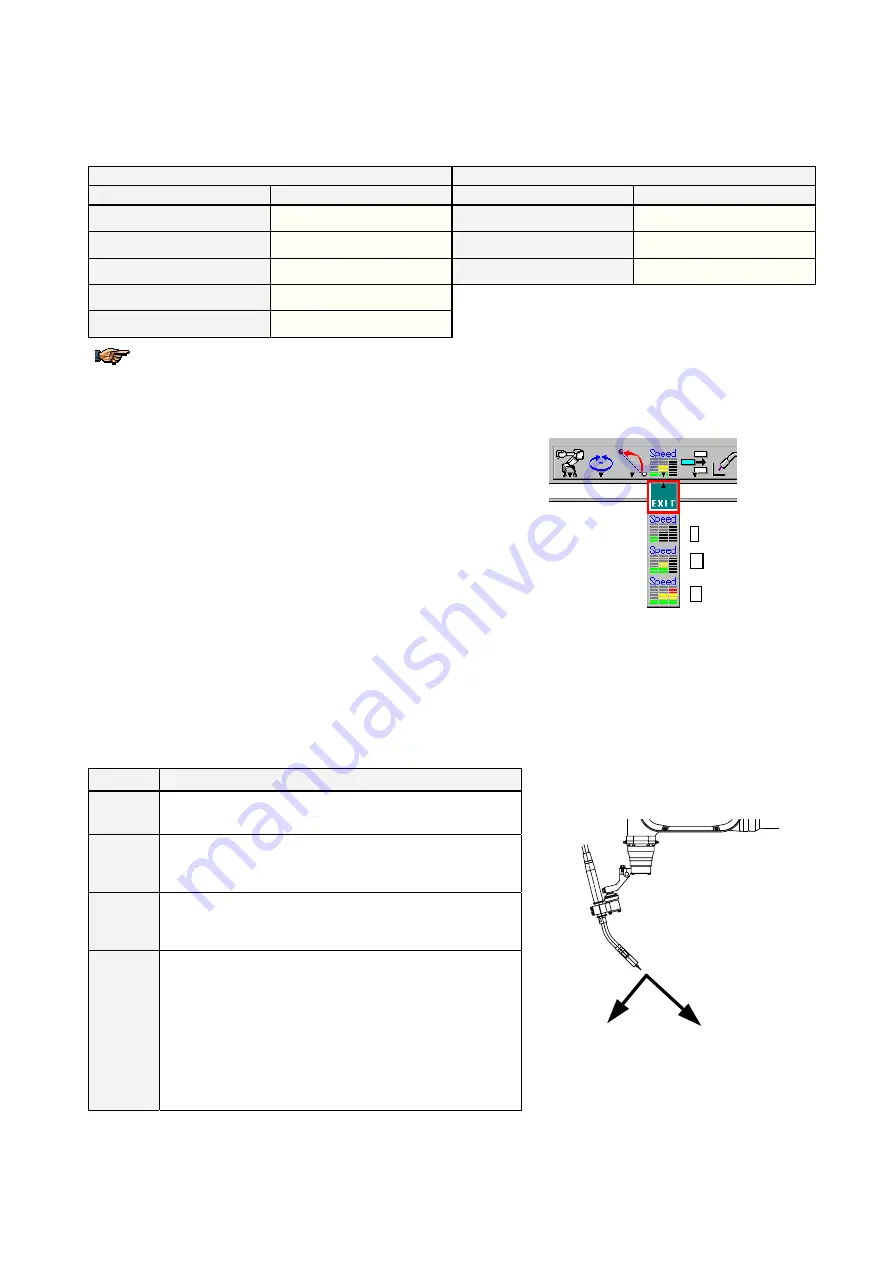

4-8-2. Change speed

Specify the robot travel speed of the tool center point (arc start

point).

Use the icon on the menu bar to switch the speed range.

L Speed (Low)

M Speed (Middle)

H Speed (High)

4-8-3. Wrist calculation (CL number)

Moving the three wrist axes (RW, BW and TW axes) to a certain position can result in what is called “singular orientation

of the robot, which can cause flip-over of the axes. In order to avoid possible flip-over of the axes, specify a calculation

type of interpolation (the CL number).

CL No.

Calculation (application)

0

Automatic calculation

1

Suitable in circular interpolation if the arc plane and the

tool vector create nearly at right angles (tolerance: within

10 degrees).

2

Suitable in circular interpolation if the arc plane and the

tool vector do not create right angle (more than 10

degrees from right angle).

3

Suitable where BW axis is nearly 0 degree (i.e. TW axis is

parallel to the RW axis).

It avoids the singular orientation error with the following

restrictions.

Teach the CL=3 section as short as possible.

Tool orientaion may not be stable in the CL=3 section.

Actual robot travel speed may be slower than teach

speed.

Tool vector

TX

TZ