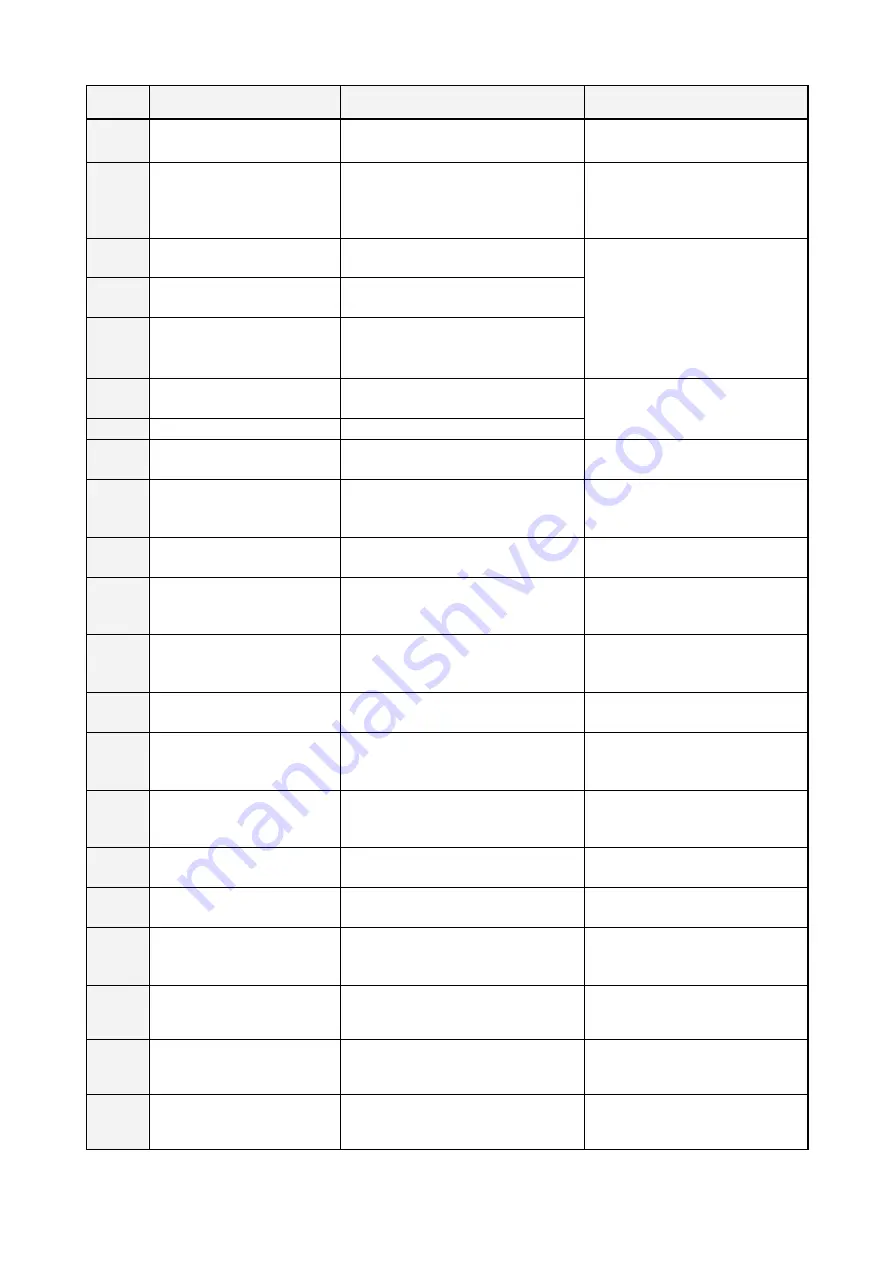

17-8

Error

code

Message

Probable Cause

Remedy

E2220

Arc sensor: Data

communication

Error in controller, or inclusion of noise.

Power to the arc sensor is OFF.

Turn off the power, and newly turn

it on.

E2230

Arc sensor: Amp. Error

Servo driver inside the spin controller

is defective. Error of the motor

temperature inside the spin head.

Remove the cover of the spin

controller and check the error

display. Investigate the cause of

the error.

E2240

Arc sensor: Operation error

Shift amount calculation error due to

error in controller or inclusion of noise.

E2260

Arc sensor: Rotational speed

RPM of the motor inside the spin head

is either too high or too low.

E2270

Arc sensor: Data

communication

Error in controller, or inclusion of

noise.

Power to the arc sensor unit is OFF.

Turn off the power, and newly turn

it on.

E2280

Arc sensor: Detection phase

Detection phase settings are not

consistent.

E2290

Arc sensor: Encoder phase

Encoder phase is out of range.

Press the Cancel key. Check the

detection phase set values.

E2320

Arc sensor: Tool number

error

Tool number 9 or higher is specified in

spin arc sensing range.

Modify the program.

E2330

Arc sensor: Arc sensing is not

available in a parallel

processing program.

Arc sense command is executed

during processing parallel programs.

Change structure of the program.

E2340

Arc sensor: Execution error

(Arc slope)

Arc slope and arc sensing is executed

in same time.

Change structure of the program.

E2350

Spin Sensor: Execution error

(Weaving)

In the "Multi-cooperative robot control"

movement, weaving and spin sensor

were executed at the same time.

Modify the program.

E3020

M-rot reset: position

Due to load inertia, external axis is not

in complete stop by the multi rotation

reset command.

Add DELAY command (about 1 to

2 seconds) in front of RSTREV

command.

E3030

Connect error (Mode)

Not accessible.

Modes do not match.

Change the mode of the slave

robot.

E3030

Connect error (Robot No.)

Not accessible.

The specified slave robot No. is

inadequate.

Check the harmonic movement

settings.

E3030

Connect error (constant)

Not accessible.

Constant of the slave robot has

changed.

Check the settings of the slave

robot.

E3040

Hold (slave err)

The slave robot stopped due to an

error.

Remove cause(s) of the error of

the slave robot.

E3050

Safety holder(slave)

Safety holder of the slave robot is

activated.

Correct the tool interference of the

slave robot.

E3060

Multi-mechanism is not set

Multi-mechanism has not specified.

Calculation area not secured.

On the

Set

menu, click

Management tool

and

System

.

Then add the “Multi-mechanism”.

E3080

COUPLE Timeout

Failed to connect to the master robot

within the preset time period after

executing COUPLE command.

Check the program.

E3100

Please turn on Servo(**)

**is Axis name.

The target independent E-axis servo

power is OFF.

Turn ON the target independent

E-axis servo power, and then

re-start.

E3110

Independent E-axis: Out of

servo off enable section

error(**) **is Axis name.

Servo power off is conducted to the

Independent E-axis to which "Servo

off enable section" is not applicable.

Turn ON the servo power on again,

and then re-start.