17-15

17-4. Supplements

17-4-1. Remedy of E1050

E1050 occurs when the actual axis position and the teaching position data do not match while the actual tool end position

and the tool orientation match their teaching data.

Probable causes

Remedies

1

In trace operation or operation, the robot moves

between two teaching points of linear interpolation

where RW axis and TW axis are taught to rotate

more than 180 degrees.

2

RW axis and TW axis are not at appropriate position

when the robot performs trace operation toward the

teaching point 1 or when the robot performs trace

operation after the wrist is manually moved.

Switch these points to PTP interpolation.

Change teaching data of the point so that the FA arm

and the BW axis create angle.

(Change the tool orientation only and keep the

current tool end position data.)

3

FA arm is nearly parallel to the BW axis (singular

orientation).

Note)

The point where the angle of BW axis is nearly 0

degree, i.e. the TW axis is parallel to the RW axis

(singular orientation), is called “Singular point”.

Add a teaching point of wrist calculation 3(CL=3) after

the singular point. (Make sure to add another

teaching point before the singular point so as to keep

the CL=3 interpolation section as short as possible.)

If there is a teaching point of linear interpolation or

circular interpolation near the singular point, the wrist

calculation 3 (CL-3) is automatically stored.

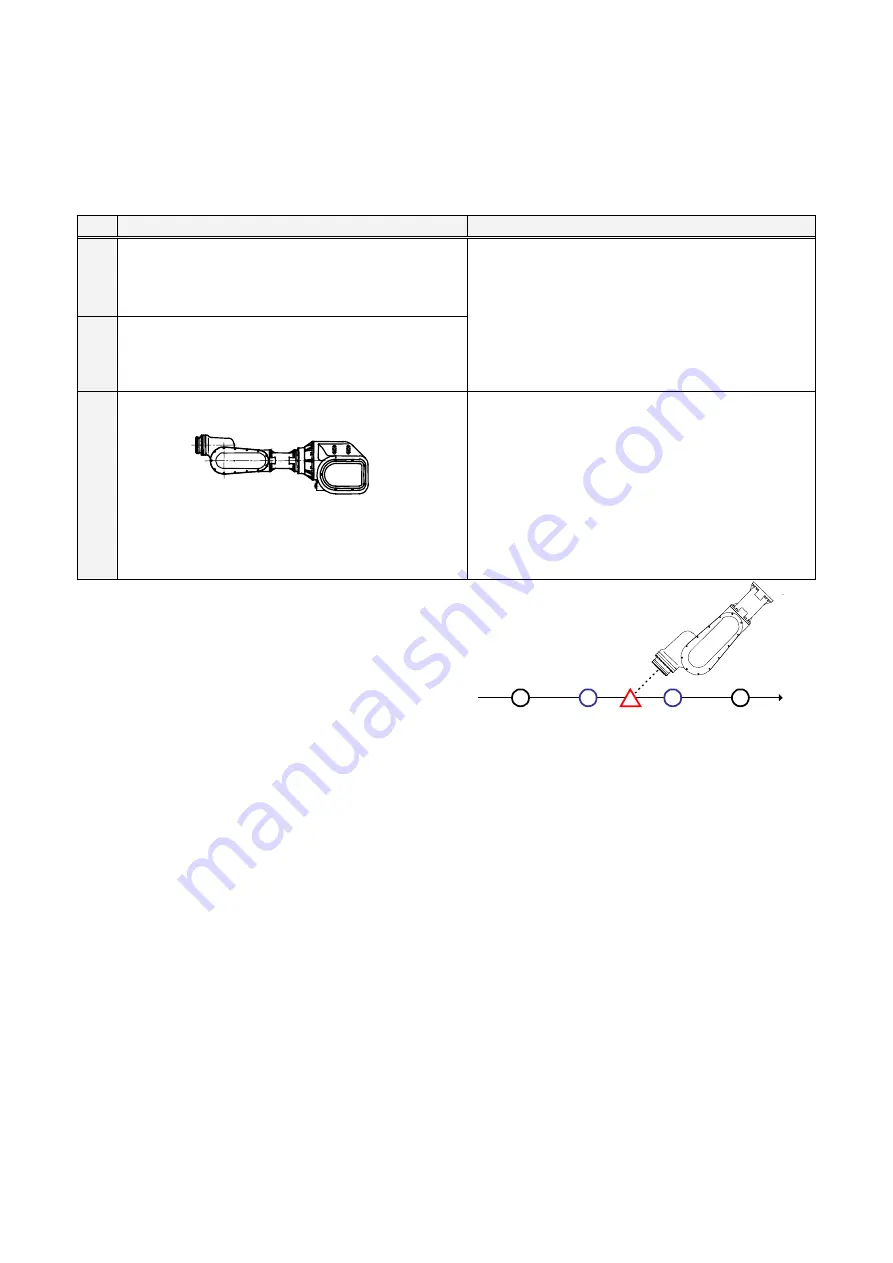

<Example>

The robot goes in an error condition at the point C

due to singular orientation of the robot when the

robot was moving from point A toward point B with

linear interpolation (see figure on the right).

Remedy:

Trace the robot backward toward the point A.

Add a teaching point of wrist calculation 0 (CL=0)

(

point D

).

Move the robot after the point of singular orientation

with Joint coordinates system.

Add a teaching point of wrist calculation 3 (CL=3)

(

Point E

).

Point

A

Point

D

Point

C

Point

E

Point

B

<Cautions>

•

The tool orientation may be unstable in the

CL=3 section (the wrist calculation is set to

3). Therefore, add another point before

the singular point (the point D) so as to

keep the CL=3 section (point D to point E)

as short as possible.

Ensure the robot operation at such section

by tracing at low speed.

•

If the CL=3 section is short but creates big

change of tool orientation, the robot travel

speed is reduced in order to ensure safe

operation.

•

To increase the robot travel speed, change

the interpolation of the teaching point from

linear to PTP and specify the speed you

want in %.