4 Connection

MITSUBISHI CNC

114

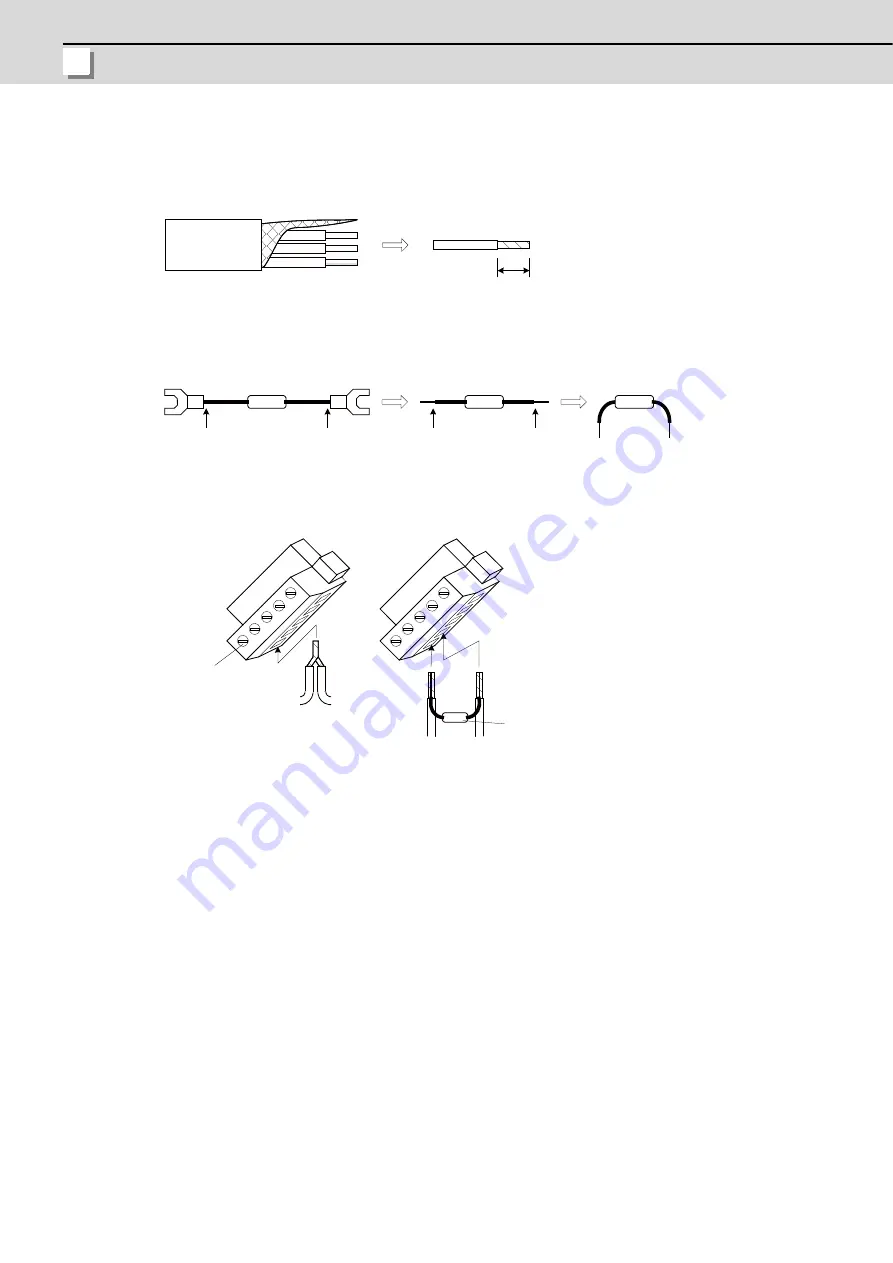

Wiring the cables to the CC-Link terminal block

(1)

Remove the sheath of the cable and isolate each internal wire from the shield mesh.

(2)

Remove the shield mesh and the coat of each internal wire. Twist the core wires.

(3)

In the intermediate station, twist together the same wires or the shield meshes of the cables from/to the

previous/next station.

(4)

In the final station, process the provided terminator as follows to attach to the station.

(5)

Insert the core wire into the opening of the terminal block. Hold the wire tight with a flat-blade screwdriver.

Check the screws on the terminal are loose enough before inserting the wires into the openings.

(6)

After wiring cables to the terminal block, Mount the terminal block into the CC-Link connector and fix it with a

flat-blade screwdriver.

7mm

Approx.

Shield mesh

Shielded twisted cable (with 3 wires)

Terminator

Shorten the

coated part

Bend the lead wires

Cut

Cut

(Note 1)

Do not solder-plate the core wire,

which leads a defective cable contact.

(Note 2)

Make sure the lead wires are kept inserted

when mounting the terminator.

DA wire

DB wire

Terminator

Flat-blade driver

To the

previous

station

To the

next

station

In the intermediate station

In the final station

Summary of Contents for M70V Series

Page 1: ......

Page 13: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 25: ......

Page 26: ...1 1 System Configuration ...

Page 36: ...11 2 General Specifications ...

Page 110: ...85 3 Installation ...

Page 120: ...95 4 Connection ...

Page 173: ...4 Connection MITSUBISHI CNC 148 ...

Page 174: ...149 付録 Ap 1 章 149 Appendix 1 Cable ...

Page 220: ...195 付録 Ap 2 章 195 Appendix 2 EMC Installation Guidelines ...

Page 232: ...207 付録 Ap 3 章 207 Appendix 3 Restrictions for Lithium Batteries ...

Page 241: ...Appendix 3 Restrictions for Lithium Batteries MITSUBISHI CNC 216 ...

Page 242: ...217 付録 Ap 4 章 217 Appendix 4 Precautions for Compliance to UL c UL Standards ...

Page 246: ......

Page 250: ......