Appendix 2 EMC Installation Guidelines

MITSUBISHI CNC

196

For details of the drive section (servo/spindle drive unit), refer to the "EMC Installation Guidelines" of instruction manuals

for each drive unit.

Appendix 2.1 Introduction

EMC Directives became mandatory as of January 1, 1996. The subject products must have a CE mark attached

indicating that the product complies with the Directives.

As the NC unit is a component designed to control machine tools, it is believed that it is not a direct EMC Directives

subject. However, we would like to introduce the following measure plans to back up EMC Directives compliance of the

machine tool as the NC unit is a major component of the machine tools.

(1) Methods of installation in control/operation panel

(2) Methods of wiring cables to outside of panel

(3) Introduction of members for measures

Mitsubishi is carrying out tests to confirm the compliance to the EMC Directives under the environment described in this

manual. However, the level of the noise will differ according to the equipment type and layout, control panel structure and

wiring lead-in, etc.

Thus, we ask that the final noise level be confirmed by the machine manufacturer.

Appendix 2.2 EMC Directives

The EMC Directives largely regulate the following two items.

- Emission Capacity to prevent output of obstructive noise that adversely affects external devices.

- Immunity Capacity to not malfunction due to obstructive noise from external source.

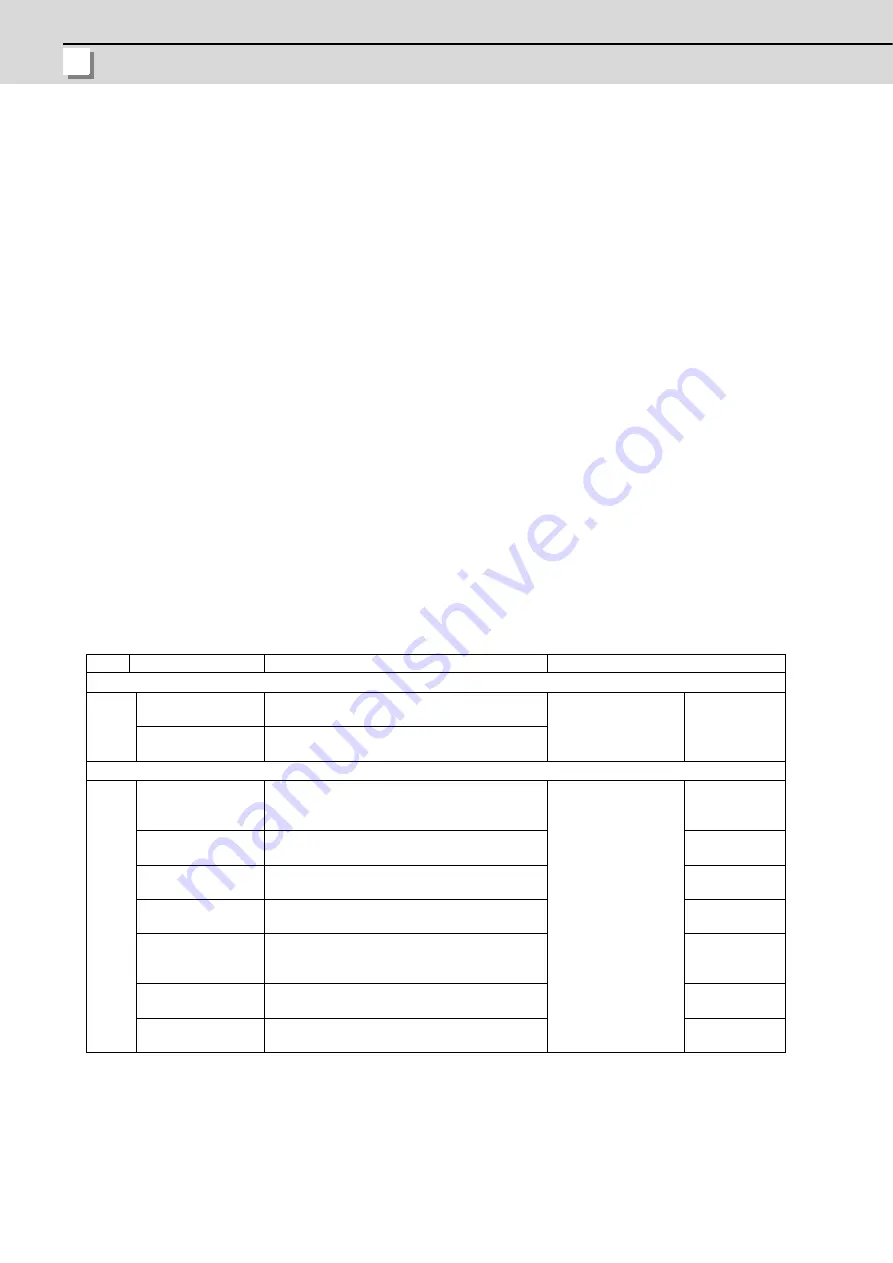

The details of each level are classified in the table below.

It is assumed that the Standards and test details required for a machine tool are the same as these.

Class

Name

Details

EN Standards

Emission

Radiated noise

Restriction of electromagnetic noise radiated through

the air

EN61000-6-4 (General

industrial machine)

EN61800-3 (Motor

control unit)

EN55011

(CLASS: A)

Conductive noise

Restriction of electromagnetic noise discharged from

power supply line

Immunity

Static electricity

electrical discharge

(Example) Regulation of withstand level of static

electricity electrical discharge accumulated in human

body

EN61000-6-2 (General

industrial machine)

EN61800-3 (Motor

control unit)

EN61000-4-2

Radiation immunity

(Example) Simulation of immunity from digital

wireless telephones

EN61000-4-3

Burst immunity

(Example) Regulation of withstand level of noise from

relay or plug and play

EN61000-4-4

Conductive immunity

(Example) Regulation of withstand level of noise

flowed from power supply wires, etc.

EN61000-4-6

Power supply

frequency magnetic

field

(Example) Regulation of electromagnetic noise of 50/

60Hz power supply frequency

EN61000-4-8

Power supply dip

(fluctuation)

(Example) Regulation of power voltage drop

withstand level

EN61000-4-11

Surge

(Example) Regulation of withstand level of noise

caused by lightning

EN61000-4-5

Summary of Contents for M70V Series

Page 1: ......

Page 13: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 25: ......

Page 26: ...1 1 System Configuration ...

Page 36: ...11 2 General Specifications ...

Page 110: ...85 3 Installation ...

Page 120: ...95 4 Connection ...

Page 173: ...4 Connection MITSUBISHI CNC 148 ...

Page 174: ...149 付録 Ap 1 章 149 Appendix 1 Cable ...

Page 220: ...195 付録 Ap 2 章 195 Appendix 2 EMC Installation Guidelines ...

Page 232: ...207 付録 Ap 3 章 207 Appendix 3 Restrictions for Lithium Batteries ...

Page 241: ...Appendix 3 Restrictions for Lithium Batteries MITSUBISHI CNC 216 ...

Page 242: ...217 付録 Ap 4 章 217 Appendix 4 Precautions for Compliance to UL c UL Standards ...

Page 246: ......

Page 250: ......