Service

46 Chiller Air-cooled Screw

The bearings used in the compressor required a small but steady quantity of oil for lubrication; the oil injection

into the compression chamber creates an oil sealing film in the compression housing for increasing the efficien-

cy and absorbing a part of heat of compression. In order to separate the oil from the mixed refrigerant gas, an

oil separator is required to ensure the least amount of oil carried into the system. Pay more attention to the oil

temperature, which has a very significant factor to the compressor bearings’ life. High oil temperature will

reduce the oil viscosity and cause the poor lubrication and heat absorption in the compressor as well. The oil

viscosity is recommended to keep over 10mm

2

/ s at any temperature. The oil temperature just keeps above

system condensing temperature to avoid the refrigerant migration into system in the summer. There is high oil

viscosity in the low ambient temperature circumstance, it could cause compressor in heavy duty to be started

up resulting less oil pressure in oil line to load the compressor. The better solution is to have higher condensing

temperature in a short time by warming up the oil.

The compressor is equipped two oil sight glasses as a standard, one is the oil high level sight glass, and the

other is the oil low level sight glass. The normal oil level in the compressor oil tank should be maintained above

the top of the low oil sight glass and in the middle level of high oil sight glass when compressor is running.

Applicable oil types are shown in the below.

UNITS

COLOR, ASTM

SPECIFIC GRAVITY

VISCOSITY

FLASH POINT

POUR POINT

T.A.N

COPPER STRIP 100°C/3hr

MOISTURE

FLOC POINT

DIELETRIC STRENGTH2.5mm

-

-

104°F

212°F

°F

°F

mg KOH/g

-

ppm

°F

KV

MOBIL EAL

ICI EMKARATE

CPI SOLEST

68

120

220

370

68

100

RL411

RL375

RL421

-

-

-

-

0.5

0.5

1.5

L2.0

L1.0

0.945

0.94

0.95

0.955

0.971

0.966

0.9723

0.9783

0.9759

64

131

215.9

385.96

62.5

95.8

48

74.1

134

8.9

14.53

20.8

29.23

8.3

10.5

7.3

10.1

15

510.8

489.2

519.8

575.6

489.2

500

523.4

474.8

509

-45.4

-33.7

-13

-5.8

-45.4

-34.6

-40

-31

-34.6

-

-

-

-

-

<0.05

<0.05

<0.05

-

-

-

-

-

-

-

-

-

-

-

-

-

<100

<100

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

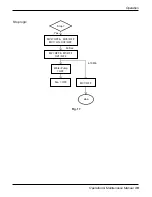

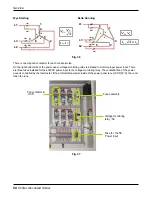

Fig. 24

Table 15