Service

Operation & Maintenance Manual 45

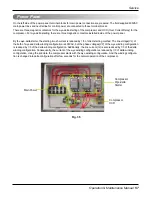

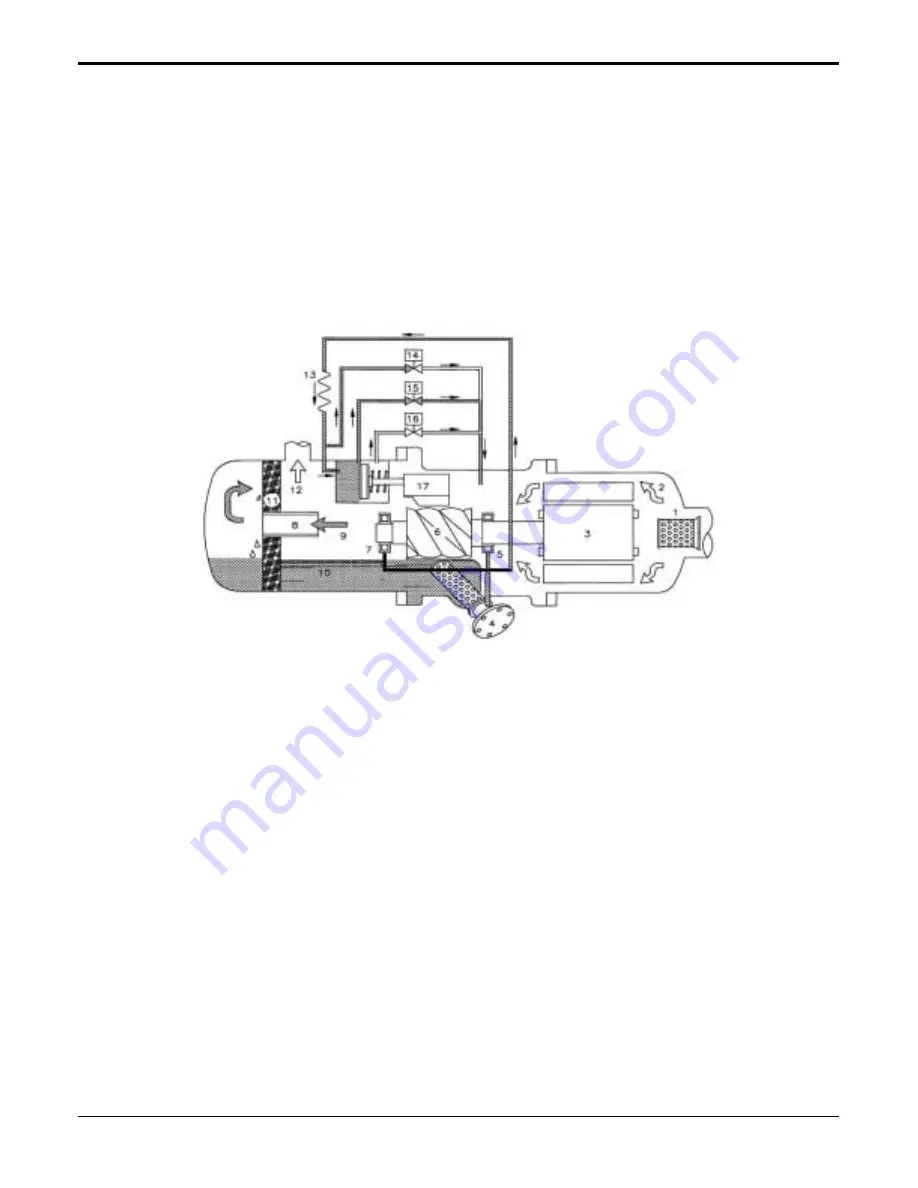

This means the displacement of refrigerant gas also increases, as a result the refrigeration capacity also

increases. However, when any of the step solenoid valve is energized, the high pressure oil in the piston cylin-

der bypasses to the suction port causing the piston and the slide valve to moved toward the left side, then some

of the refrigerant gas by pass from the compression chamber back to the suction end. As a result, the refrigera-

tion capacity decreases because of the reduction of displacement of refrigerant gas flowing in the system. The

piston spring is used to push the piston back to its original position, i.e. minimum load position in order to

reduce the starting current for the next starting-up. If the compressor started at full load capacity it may result in

over current start. The capillary is used to maintain and restrain a suitable amount of oil flow into the cylinder.

If the oil filter cartridge, capillary, or modulation solenoid valves are not working well in the capacity control sys-

tem, this may result in the abnormality and ineffectiveness of the capacity control system.

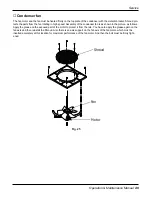

The main functions of the lubrication oil in the screw compressor are lubrication, internal sealing, cooling and

capacity control. The positive oil pressure in the cylinder pushes the piston and the slide valve that is connected

by a piston rod to move forward and backward in the compression chamber. The design with positive pressure

differential lubrication system in the screw compressor is available to omit an extra oil pump in the compressor

like reciprocating compressor. However, in some special applications, it is still necessary to install an extra oil

pump to the compressor for safety.

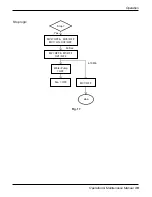

Fig. 23