General

Operation & Maintenance Manual 19

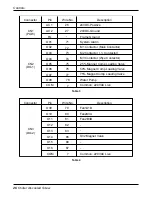

Parameter Setting

Fig. 7

Par. Setting

System Setting

Delay Setting

Content

Fan Start Temp3

Fan Start Temp2

Fan Start Temp1

Load Interval

Limit Temp

Low Temp

Outage DT

Restart DT

H Exhaust Temp

90.0

°

C

SET

SET

10.0~20.0

1.0~5.0

1.0~3.0

SET

1.0~3.0

34.0~37.9

29.0~33.9

25.0~28.9

29.0~200.0

35.0

°

C

30.0

°

C

26.0

°

C

60S

15.0

°

C

2.0

°

C

2.0

°

C

2.0

°

C

80.0~150.0

The system setting is composed of 3 screen cuts. Through the parameter setting, the control parameters of control oper-

ations can be identified and changed. To initiate the change, press the SET key. With confirming highlighted item after

pressing the SET key, the operator can change the value of a digit of the selected item by the arrow keys

or can

change the selected digit by the arrow keys

. After changing the value of all digits of the selected item, pressing

ENT makes the highlighted item to be changed to the next one. Pressing ESC during changing makes the changed to

be canceled.

Firstly, Fan control transition points (fan full opening, fan off1, and Fan off2) can be configured. From the transition

points, fan full opening means the condenser refrigerant leaving temperature setpoint for running all condenser fans.

When actual temperature is over the setpoint, all condenser fans must run. Similarly, the fan off1 means the condenser

refrigerant leaving temperature setpoint for running 8 condenser fans. And the fan off2 means the condenser refrigerant

leaving temperature setpoint for running 6 condenser fans. Consequently, minimum 6 condenser fans run when the

chiller operates, and the number of condenser fans is proportional to the condenser refrigerant leaving temperature. The

configurable range is shown in the below picture.

Secondly, system clock can be also changed here.

The compressor discharge alarm point temperature cannot be changed only, only informative to operator.

The load limit temp is the temperature setpoint where the capacity override is activated. When the chilled water leaving

temperature is over the value, the compressor is prevented from running with 100% capacity and the capacity of the

compressor is limited to 75%.

The anti-freezing temp is another method to protect the chiller from too low chilled water temperature additional to anti-

freezing switch shown in I/O display.