Start-up

32 Chiller Air-cooled Screw

Do not manually operate contactors. Serious damage to the machine may result. The following procedure

should be followed.

• Be sure that water side load such as air-handling equipment, or other equipment to which the chiller supplies

liquid are working. Starting of the water side load equipments can be delayed if the chilled water temperature

is too high.

• Be sure that water circulating pump is operating if not on automatic control from the chiller.

• Check and inspect all fuses. All fuses inside of the power panel and control panel should be properly located

and maintained.

• Switch on the unit circuit breaker and switch on the start switch installed on the door of control panel.

• Check and inspect the status of the LEDs of the PLC (Programmable Logic Controller) and the HMI (Haman

Machine Interface) unit. The HMI unit should display welcome screen after switching on.

• Check and inspect the voltage monitoring relay inside of the power panel. The relay should not indicate any

fault code.

• Using the HMI unit, configure chilled water leaving temperature setpoint.

• Start the system by setting the unit start menu on HMI Unit.

• After running the unit for a short time, check the oil level in each compressor, rotation of condenser fans and

check for flashing in the refrigerant sight glass.

• Ambient temperature during unit operating must be within 64.4°F ~ 129.2°F(18°C ~ 54°C).

• To obtain proper temperature control, water loop volume must be within allowable range of the volume.

■

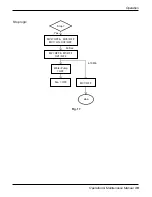

Start-Up Procedure