Controls

22 Chiller Air-cooled Screw

Among the menu items, some items are protected from access with authorization code system. The user setting is pro-

tected with user code, and delay setting, system setting, and parameter setting are protected from system code. The

dual authorization code system enables only authorized operators to configure operation settings, and also enable only

service engineers to configure control parameter settings.

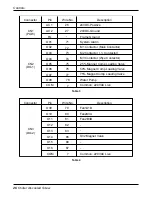

The functions of the LEDs are shown in the below table. Through the LED, the operators can identity the status of chiller

control without any manipulation.

Fig. 10

Main Menu

User Setting

I/O Display

Alarm Display

System Setting

Para. Setting

Delay Setting

Hand/Auto

Mode

Control Mode

Start Interval

Expiration

Chilled Water

In Temp

Ambient

Temp

Exhaust

Temp

Chilled Water

Out Temp

Condensate

Temp

Comp

Running Hour

Running

Capacity

Target Temp

Outage Temp

Restart Temp

Hand/Auto

Mode

System Clock

Control Mode

Oil Preheating

Delay

Schedule

Program

Amendable Item

Remote

Control Input

Oil Check

System Input

Comp Contactor

Contact Inputs

Low Temp

Switch Input

Pressure

Switch Input

Phase

Protect Input

Chilled Water

Flow Input

Differential

Pressure Input

Compressor

Overload Input

Fan Contactor

Contact Inputs

Emergency

Switch Input

Alarm

Output

Comp Contactor

Outputs

Solenoid Valve

Output

Fan Contactor

Outputs

Pump Output

Alarm Clear

Current Alarms

Protected with

User Code

Protected with

System Code

Protected with

System Code

Protected with

System Code

Chilled Water In

Temp Amending

Chilled Water Out

Temp Amending

Cond Ref Out

Temp Amending

Ambient

Temp Amending

Comp Discharge

Temp Amending

Comp Running

Hour Clear

Fan Control

Transition Temp

Fan Load

Interval

Comp Discharge

Temp Hi Limit

Chilled Water Out

Temp Hi Ovrd

Outage Temp

Restart Temp

Start Interval

Comp Start

Delay

Comp Stop

Delay

Oil Preheat

Delay

Fan Control

Feedback

Comp Control

Feedback

System Code

Comp Overload

Delay

Differential

Pressure Delay

Fan Shutdown

Delay

Discharge Temp

Delay

MODBUS

Usage

System Clock

Status Message

Control Mode

MODBUS

Usage

User Code

Comp Loading

Valve Outputs