Trouble Shooting

68 Chiller Air-cooled Screw

If a stoppage occurs more than once as a result of any of the safety devices, determine and

correct the cause before attempting another restart.

TROUBLE SHOOTING

General Malfunction

Before specific alarm trouble shooting, general troubles and their possible remedies are introduced.

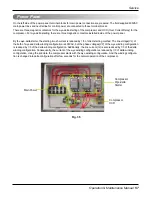

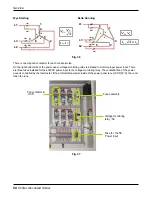

When the unit does not run at all, you have to check power supply to the chiller, refrigerant, configuration, and alarm

invocation. For the power supply check, you have to check voltage applied to the terminal block inside of the power

panel. If the power is absent, please check power feeder and check whether any protective device is tripped.

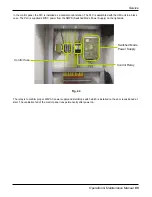

When the power is applied properly, refrigerant pressure must be inspected by pressure gauge installed on the chiller,

when the pressure is out of range, please check whether any leakage point is by soap bubble test. If there is problem

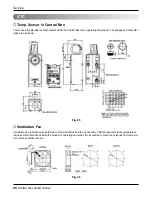

with the configuration of the PLC or too much delay is configured, the chiller will not start or the start is delayed for long

time. Please recover the configuration value to factory setting before starting the chiller. Lastly, alarm invocation has to

be checked. You can find whether any alarm is invoked through the HMI unit. Follow specific alarm trouble shooting

procedure if any alarm is invoked.

Normally, the compressor of the chiller will cycle according to the chilled water leaving temperature, the compressor

shutdown temperature and the compressor restart temperature. But the case where the compressor runs too long

without cycling can be encountered. When the refrigerant is not enough, the chiller will operate continuously because

the chiller cannot work at 100% power. At this case, the leakage is also to be inspected. When magnetic contactors for

the compressor are mechanically welded, the chiller operation will be continued, because the PLC cannot stop the

compressor by control signal even if the compressor must be stopped. When there is no problem with the refrigerant

and compressor contactor, Air inside of the water loop can be a cause, because air inside of water loop obstructs ther-

mal exchange. When the problem is revealed, the air must be purged. When there is non-condensables in the refriger-

ant circuit, remove the refrigerant and recharge.

Even after running condenser fan and chilled water pump, the compressor will not run caused by alarm or trouble with

temperature reading. Please follow specific alarm trouble shooting procedure at this case.