31

Tr

oubleshooting

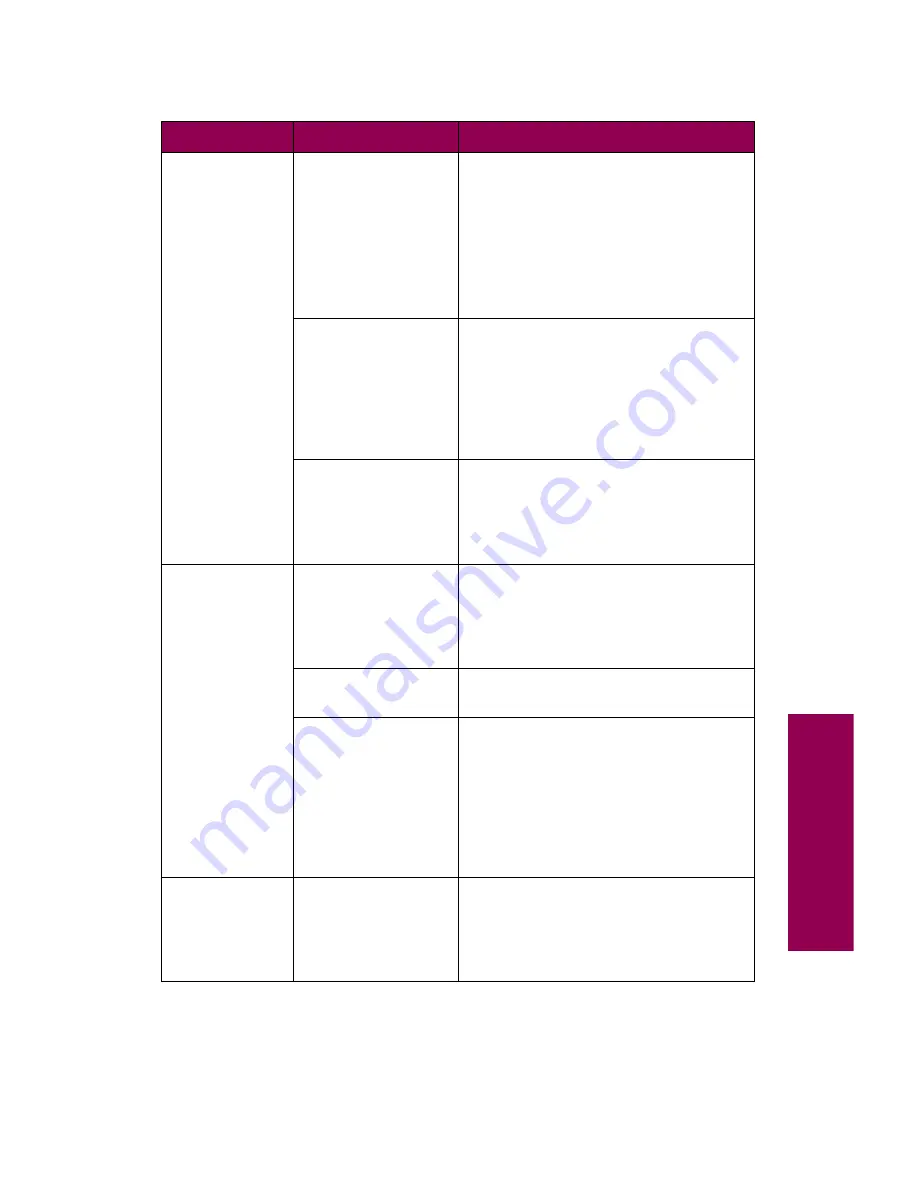

Jobs don’t print

(

continued).

Your MarkNet

™

print server is not

set up properly or is

not connected

properly.

Verify that you have properly set up the

network address and that the network

cable is securely connected.

Refer to the

Setup Guide or to the

Drivers, MarkVision and Utilities CD for

information. After launching the CD,

click

View Documents

and then click

MarkNet Print Servers

.

Port settings are

incorrect.

Make sure the current communications

settings are correct. Refer to the

Setup

Guide for information on configuring

MarkNet ports. Refer to the

Complete

Printer Reference on Lexmark’s Web

site for information on parallel, serial,

fax, or LocalTalk port settings.

You are using the

wrong interface

cable, or the cable is

not securely

connected.

Make sure you are using a recom-

mended printer cable. Refer to the

Setup Guide for cable specifications.

It takes longer

than expected

to print a job.

The job is too

complex.

Reduce the complexity of your print job

by eliminating the number and size of

fonts, the number and complexity of

images, and the number of pages in

the job.

Page Protect is On.

Set Page Protect Off from the Setup

Menu.

The resolution is set

to 1200 Image

Quality.

If your job includes complex images, it

may take longer to print when the

resolution is set to 1200 Image Quality.

To print the job faster, select another

print resolution from the printer driver

before sending the job to print. You

may notice some reduction in print

quality.

The job prints

from the wrong

tray or on the

wrong print

material.

The printer driver

settings are

overriding the

operator panel

menu settings.

Make sure the Paper Size and Paper

Type specified in the printer driver are

correct for the job you are printing.

Other printing problems (continued)

Symptom

Cause

Solution

Summary of Contents for 12L0103

Page 1: ...OptraTM W810 User s Reference...

Page 6: ...vi Table of contents...

Page 14: ...xiv Preface...

Page 54: ...40 Troubleshooting...

Page 60: ...46 Clearing jams 3 Pull the jammed paper straight out 4 Close the jam access door...

Page 88: ...74 Clearing jams 11 Open the finisher top cover Cover M...

Page 103: ...89 Loading paper 2 Press down on the pressure plate until it clicks into place...

Page 106: ...92 Loading paper b Lift the paper guide up and out of the tray...

Page 126: ...112 Replacing supplies To install a new toner cartridge 1 Open the toner box cover Cover A...

Page 137: ...123 Replacing supplies 13 Push the cartridge into the printer as far as it will go...

Page 142: ...128 Replacing supplies 6 Press the green tab and push the paper dust remover into place...

Page 152: ...138 Replacing supplies b Swing the cover up toward the printer until it snaps into place...

Page 156: ...142 Replacing supplies 3 Loosen the two fuser retaining screws...

Page 159: ...145 Replacing supplies 8 Tighten the two fuser retaining screws...

Page 168: ...154 Replacing supplies...

Page 190: ...176 Finisher...

Page 196: ...182 Mailbox 5 Push the two covers onto the mailbox s legs as shown...

Page 201: ...187 Mailbox 7 Replace the bottom plate...

Page 216: ...202 Removing options 4 Slide the hard disk out of the bracket...

Page 234: ...220 Print and hold...

Page 242: ...228 Menus...