K134sm8e6

8-154

Reference

Auto Initial Cut after Long Print

It tends to happen that the machine cuts a roll media at an angle toward the feeding direction

when some sheets of long length prints are performed continuously. When the next print is

started afterward with having non-right angle on the leading edge, media feeding for that

print may become unstable and incorrect, and it may cause print quality defect.

If the leading edge is trimmed before starting next printing, it helps to have right angle on the

leading edge and eventually allows for correct and stable media feeding. KIP7170 has a

feature called “Auto Initial Cut after Long Print” that automatically takes trim cut between long

length prints as long as necessary conditions are satisfied.

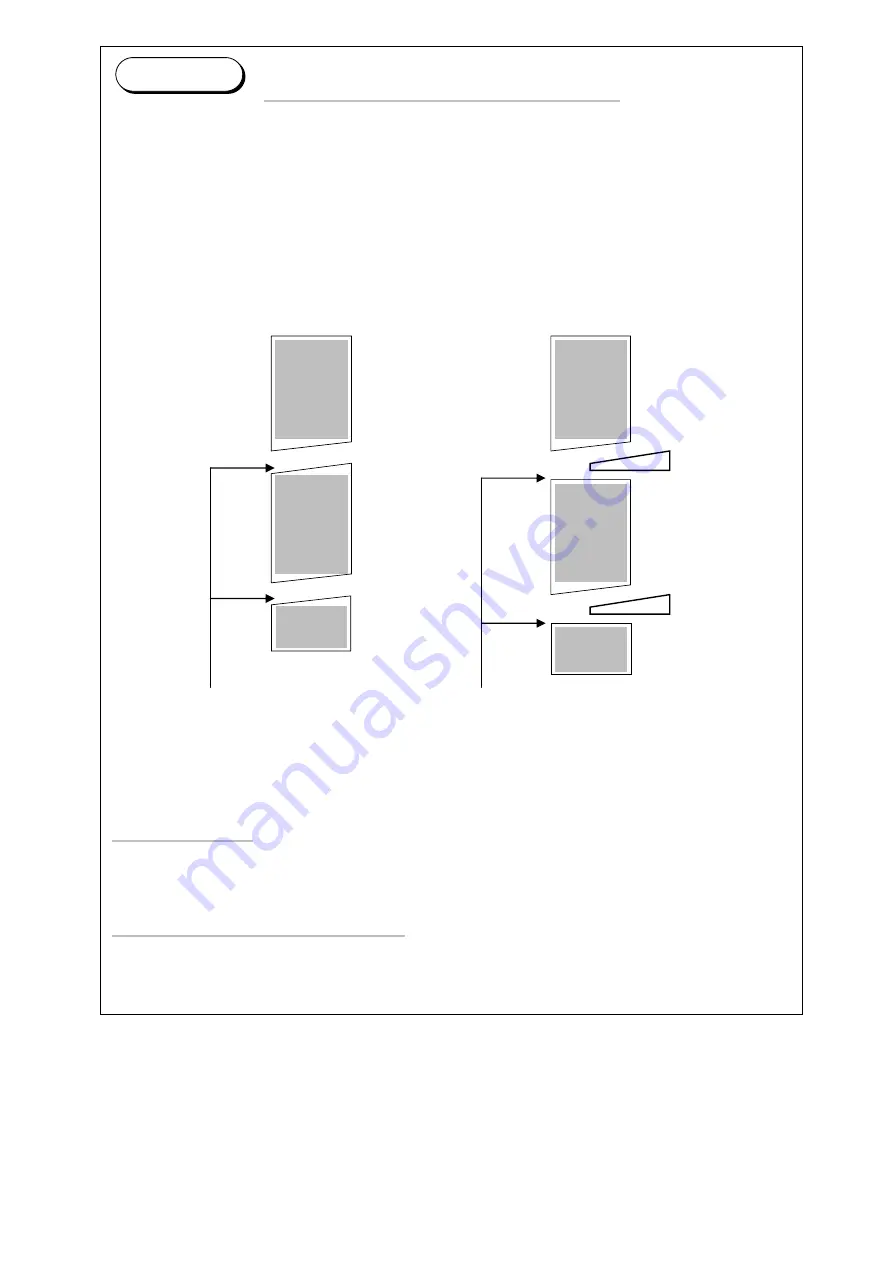

Without Auto Initial Cut With Auto Initial Cut

Non-right angle on LE Right angle on LE

(No good) (Good)

Necessary conditions that must be satisfied are “length of long print” and “Continuous

number of long length prints”. When both conditions are satisfied the Suto Initial Cut after

Long Print takes trim cut.

Length of long print

Printer has a definition value for long length print, which is configured by the item No.753. If a

print is longer than this definition value, this print is judges as long length print and 1

st

condition for Auto Initial Cut is satisfied. If shorter, it is not judged as long length prin.

Continuous number of long length prints

Auto Initial Cut after long print functions when certain sheets of long length prints are

continuously performed. Definition for “certain sheets” is configured by the item No.754. If it

is set to 3 for example, printer takes trim cut after printing 3 sheets of long length prints

continuously.

Long print

Long print

Long print

Long print

Trim cut

Trim cut

Summary of Contents for 7170K

Page 1: ...KIP 7170K Service Manual Version A...

Page 46: ...K134sm2e5 2 28 7 Press GUIDES 8 Press Help 9 Press Settings SETTINGS screen appears...

Page 76: ...K134sm2e6 2 58 31 Type 4 with keypad and then click OK on the bottom 32 Click OK on the bottom...

Page 108: ...K134sm4e1 4 4 120V model 230V model 8 7 10 11 12 15 14 13 9...

Page 189: ...K134sm5e4 5 36 64 Press GUIDES 65 Press Help...

Page 384: ...K134sm5eH 5 231 3 Remove both Covers 3 5 6 pulling their sides outward 5 6...

Page 395: ...K134sm5eH 5 242 6 Remove the Blower 9 BL3 BL4 moving as the following photos 9 9...

Page 502: ...K134sm6e1 6 15...

Page 563: ...K134Ksm8e2 8 4 4 Press GUIDES 5 Press Help...

Page 564: ...K134Ksm8e2 8 5 6 Press Setting to indicate SETTINGS page...

Page 594: ...K134Ksm8e2 8 35 2 Press All Items 3 Press Export...

Page 747: ...K134Ksm8e7 8 188 8 9 2 Operation in Error Mask 1 Press Error Mask...

Page 749: ...K134Ksm8e7 8 190 8 9 3 Operation in Jam Mask 1 Press Jam Mask...

Page 750: ...K134Ksm8e7 8 191 2 Select the desired target...

Page 754: ...K134Ksm8e7 8 195 8 11 2 Changing Counter Value 1 Press Total Count 2 Press Edit...

Page 756: ...K134Ksm8e7 8 197 5 Press Edit to enable new value 6 Close the following message pressing OK...

Page 777: ...K134Ksm8e7 8 218 8 19 Communication Reset NOTE This function is not used in the market...

Page 839: ...K134sm8e8 8 280 29 Double click on the row No 15 Stitch Setting 1...

Page 863: ...K134sm9e1 Chapter 9 Appendix...

Page 864: ...KIP 7170 Overall Circuit Diagram USA 120V_KCS...