K134sm7e2

7-24

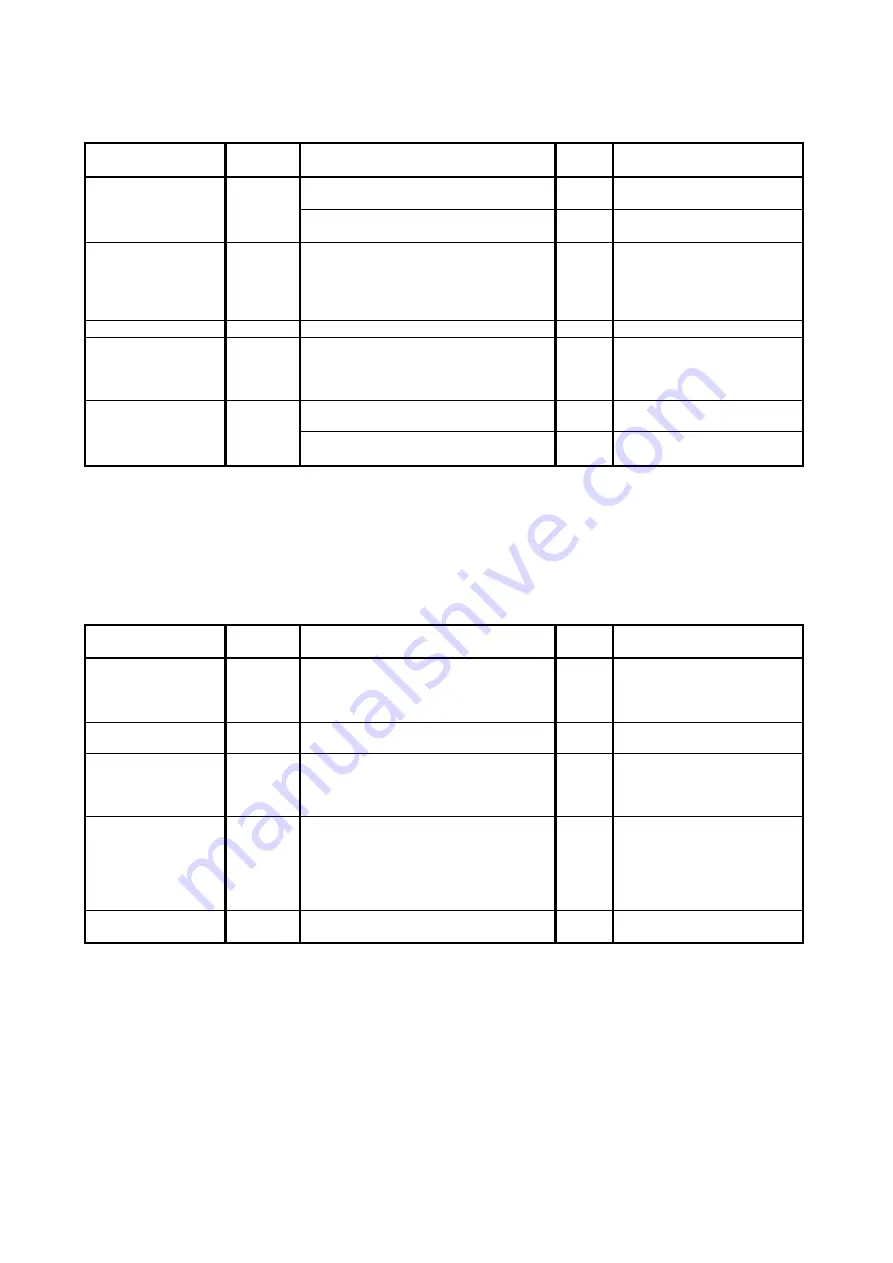

7. 2. 2. 4 Density is uneven

Check the following matters with the Pattern Print, pattern: #01_00 and pattern: #03_00.

If necessary use other Test Patterns.

Cause

Checking

order

Checking

Result

Treatment

Image Corona

1

Is the Image Corona dirty?

Yes

Clean the Image Corona, or

replace the Corona Wire.

Is the height of Corona Wire different

between left and right?

Yes

Adjust the height properly.

Installation of

Developer Unit

2

Is the Developer Unit firmly pressed

toward the Drum? (Do Counter Rollers

at both sides of the Developer Roller

touch the Drum Unit?)

No

Remove the Developer Unit,

and then install it to the

machine correctly.

Check the Developer Press

Unit.

LED Head

3

Is the Lens Array dirty

Yes

Clean it.

Eraser Lamp

4

Are all LED of the Eraser Lamp light

properly during the print?

No

1. Replace the Eraser

Lamp.

2. Replace the PW13420

PCB.

Developer Unit

5

Is the Developer Roller evenly covered

with the toner?

No

1. Clean Regulation Roller.

2. Reinstall Scraper.

Is the toner accumulating evenly in the

Developer Unit?

No

Level the machine correctly.

7. 2. 2. 5 Totally appeared foggy image

Check the following matters with the Pattern Print, pattern: #01_00 and pattern: #04_00.

If necessary use other Test Patterns.

Cause

Checking

order

Checking

Result

Treatment

1

Try to readjust each image creation

component according to [7.2.1 Basic

Image Adjustment].

Is the problem fixed?

Yes

OK

Developer Unit

2

Is the Developer Roller insulated from

the ground?

No

Check the Developer Roller

and connector.

Image Corona

3

Is the foggy image printed even if you

print a completely white pattern?

Yes

Check the output voltage

from the HV Power Supply

to the Image Corona.

If it is not correct, readjust it.

Developer Bias

4

Is the Developer Unit supplied with a

correct Developer Bias during the print?

No

Check the output voltage

from the HV Power Supply

to the Developer Unit.

If it is not correct, readjust it.

Or replace the HV Power

Supply PCB

Photoconductive

Drum

5

Have you used the Photoconductive

Drum longer than its part life?

Yes

Replace the

Photoconductive Drum.

Summary of Contents for 7170K

Page 1: ...KIP 7170K Service Manual Version A...

Page 46: ...K134sm2e5 2 28 7 Press GUIDES 8 Press Help 9 Press Settings SETTINGS screen appears...

Page 76: ...K134sm2e6 2 58 31 Type 4 with keypad and then click OK on the bottom 32 Click OK on the bottom...

Page 108: ...K134sm4e1 4 4 120V model 230V model 8 7 10 11 12 15 14 13 9...

Page 189: ...K134sm5e4 5 36 64 Press GUIDES 65 Press Help...

Page 384: ...K134sm5eH 5 231 3 Remove both Covers 3 5 6 pulling their sides outward 5 6...

Page 395: ...K134sm5eH 5 242 6 Remove the Blower 9 BL3 BL4 moving as the following photos 9 9...

Page 502: ...K134sm6e1 6 15...

Page 563: ...K134Ksm8e2 8 4 4 Press GUIDES 5 Press Help...

Page 564: ...K134Ksm8e2 8 5 6 Press Setting to indicate SETTINGS page...

Page 594: ...K134Ksm8e2 8 35 2 Press All Items 3 Press Export...

Page 747: ...K134Ksm8e7 8 188 8 9 2 Operation in Error Mask 1 Press Error Mask...

Page 749: ...K134Ksm8e7 8 190 8 9 3 Operation in Jam Mask 1 Press Jam Mask...

Page 750: ...K134Ksm8e7 8 191 2 Select the desired target...

Page 754: ...K134Ksm8e7 8 195 8 11 2 Changing Counter Value 1 Press Total Count 2 Press Edit...

Page 756: ...K134Ksm8e7 8 197 5 Press Edit to enable new value 6 Close the following message pressing OK...

Page 777: ...K134Ksm8e7 8 218 8 19 Communication Reset NOTE This function is not used in the market...

Page 839: ...K134sm8e8 8 280 29 Double click on the row No 15 Stitch Setting 1...

Page 863: ...K134sm9e1 Chapter 9 Appendix...

Page 864: ...KIP 7170 Overall Circuit Diagram USA 120V_KCS...