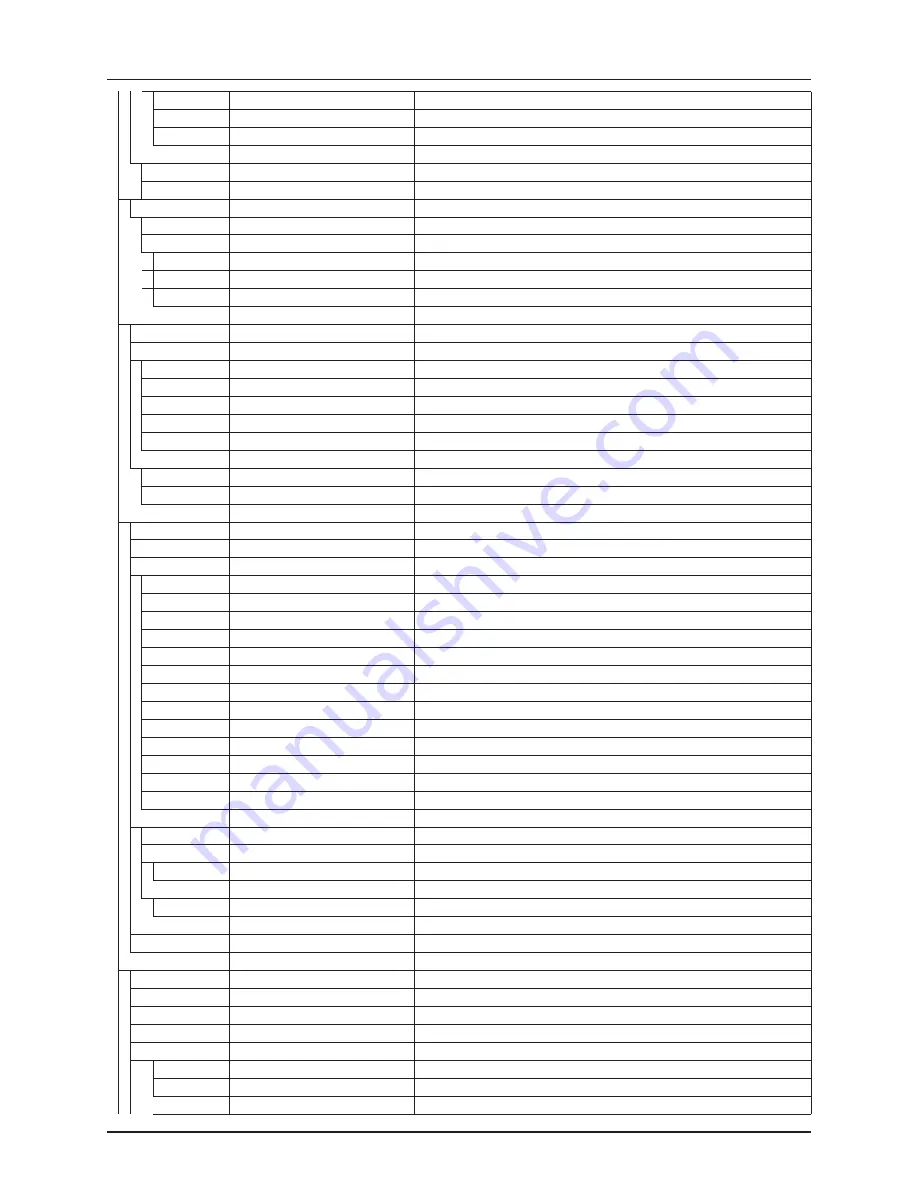

3 - Description

3.20

3. 1.

1. 2. 1

Sprayer practical

Measure up a distance more than 70 meters or 200 feet. Then drive distance

3. 1.

1. 2. 2

Now key in the exact distance, measured by a measuring tape

3. 1.

1. 2. 3

This is the new constant (pulses per meter or feet)

3. 1. 2

Tractor Alpha speed

Alpha, or sensor located on tractor Sensor cable connected to Terminal

3. 1. 2.

1

Tractor speed constant

3. 1. 2.

2

Tractor practical

Preferred method. Do in field with spray tank half full for most accurate result

3. 1. 3

Radar speed

Choose if radar speed sensor is used

3. 1. 3.

1

Radar speed constant

Shows and permits change to the constant, Pulses Per Unit (meter / feet)

3. 1. 3.

2

Radar practical

Preferred method. Do in field with tank half full for most accurate result

3. 1.

3. 2. 1

Measure up a distance more than 70 meters or 200 feet. Then drive distance

3. 1.

3. 2. 2

Now key in the exact distance, measured by a measuring tape

3. 1.

3. 2. 3

This is the new constant (pulses per meter or feet)

3. 2

Flow calibration

Flow sensor calibration. Theoretical (PPU), Nozzle Tank method PrimeFlow

3. 2. 1

PPU theory method

EU: dia/ca PPU: Ø13/120, Ø20/60, Ø36/17 US: dia/ca PPU: Ø13/485, Ø20/225, Ø36/60

3. 2. 2

Nozzle method

Practical flow calibration, by checking the actual nozzle output per minute

3. 2. 2.

1

Nozzle method

measure the flow per minute from a number of nozzles. Press Enter.

3. 2. 2.

2

Nozzle method

Key in the averaged actual flow value and press Enter

3. 2. 2.

3

Nozzle method

This is the PPU constant from the volume previously just measured

3. 2. 2.

4

Open all sections

3. 2. 2.

5

Close end nozzles, Bi-jet nozzles

3. 2. 3

Tank method

Practical flow calibration done by emptying over half the tank

3. 2. 3.

1

Tank method

The sprayed amount is counted up when the sections are opened

3. 2. 3.

2

Tank method

Press Enter. The shown volume is adjusted to match the actual volume

3. 3

Boom setup

Boom width, number of sections and number of nozzles for each section

3. 3. 1

Width

The total spray boom width. Include end nozzles if fitted

3. 3. 2

Number of sections

The number of spray boom sections. Key in, then press Enter

3. 3. 3

Nozzles / sections

To set up no. of nozzles per section. Screens for each section will appear

3. 3. 3.

01

Section 1

Use arrow keys or numeric keys, then press Enter to set up section 1

3. 3. 3.

02

Section 2

Use arrow keys or numeric keys, then press Enter to set up section 2

3. 3. 3.

03

Section 3

Use arrow keys or numeric keys, then press Enter to set up section 3

3. 3. 3.

04

Section 4

Use arrow keys or numeric keys, then press Enter to set up section 4

3. 3. 3.

05

Section 5

Use arrow keys or numeric keys, then press Enter to set up section 5

3. 3. 3.

06

Section 6

Use arrow keys or numeric keys, then press Enter to set up section 6

3. 3. 3.

07

Section 7

Use arrow keys or numeric keys, then press Enter to set up section 7

3. 3. 3.

08

Section 8

Use arrow keys or numeric keys, then press Enter to set up section 8

3. 3. 3.

09

Section 9

Use arrow keys or numeric keys, then press Enter to set up section 9

3. 3. 3.

10

Section 10

Use arrow keys or numeric keys, then press Enter to set up section 10

3. 3. 3.

11

Section 11

Use arrow keys or numeric keys, then press Enter to set up section 11

3. 3. 3.

12

Section 12

Use arrow keys or numeric keys, then press Enter to set up section 12

3. 3. 3.

13

Section 13

Use arrow keys or numeric keys, then press Enter to set up section 13

3. 3. 4

End nozzles and Bi-jet nozzles

If end nozzles are fitted. Set value to equivalent coverage by boom nozzles

3. 3. 4.

1

None

If no end nozzles or Bi-jet nozzles are fitted, select this

3. 3. 4.

2

End nozzles fitted

Select if end nozzles are fitted

3. 3.

4. 2. 1

End nozzles

Key in 'n', number of regular nozzles equivalent to the end nozzle coverage

3. 3. 4.

3

Bi-jet fitted

Select if Bi-jet nozzles are fitted

3. 3.

4. 3. 1

Bi-jet end nozzles

3. 3. 5

Length hitch to axle for ASC

Length from hitch to axle on sprayer for AutoSectionControl for ISObus

3. 3. 6

Length axle to boom for ASC

Length from axle on sprayer to boom for AutoSectionControl for ISObus

3. 4

Regulation user setup

Setup of pressure filter, nozzle, ASC default

3. 4. 1

Flow sensor restriction

Flow to obtain 1 bar (15 psi) pressure drop over pressure filter and flow sensor

3. 4. 2

Simulated speed value

Type in speed for priming at stand still and when both flow and pressure are defect

3. 4. 3

Nozzle size flow at 3 bar (45 psi)

0075Pink = 0.3 02Yellow = 0.8 04Red = 1.6 08White = 3.2 l/min

3. 4. 4

Dual line second nozzle

0075Pink = 0.3 02Yellow = 0.8 04Red = 1.6 08White = 3.2 l/min

3. 4. 5

Type of nozzle

Select Regular or QuintaStream nozzle

3. 4.

5. 1

Regular nozzle

Flat fan, Low drift, Minidrift

3. 4.

5. 2

QuintaStream

QuintaStream fertilizer nozzle

3. 4. 6

Regulation parameter

Code for special machines or applications, consult your dealer

Summary of Contents for ISOBUS VT

Page 2: ......

Page 4: ......

Page 8: ...Table of contents TOC 4 ...

Page 10: ...1 Welcome 1 2 ...

Page 12: ...2 Safety notes 2 2 ...

Page 48: ...5 Menu 1 Daily settings 5 2 ...

Page 52: ...6 Menu 2 Setup 6 4 ...

Page 74: ...8 Menu 4 Toolbox 8 4 ...

Page 78: ...10 Maintenance 10 2 ...

Page 103: ......