3 - Description

3.22

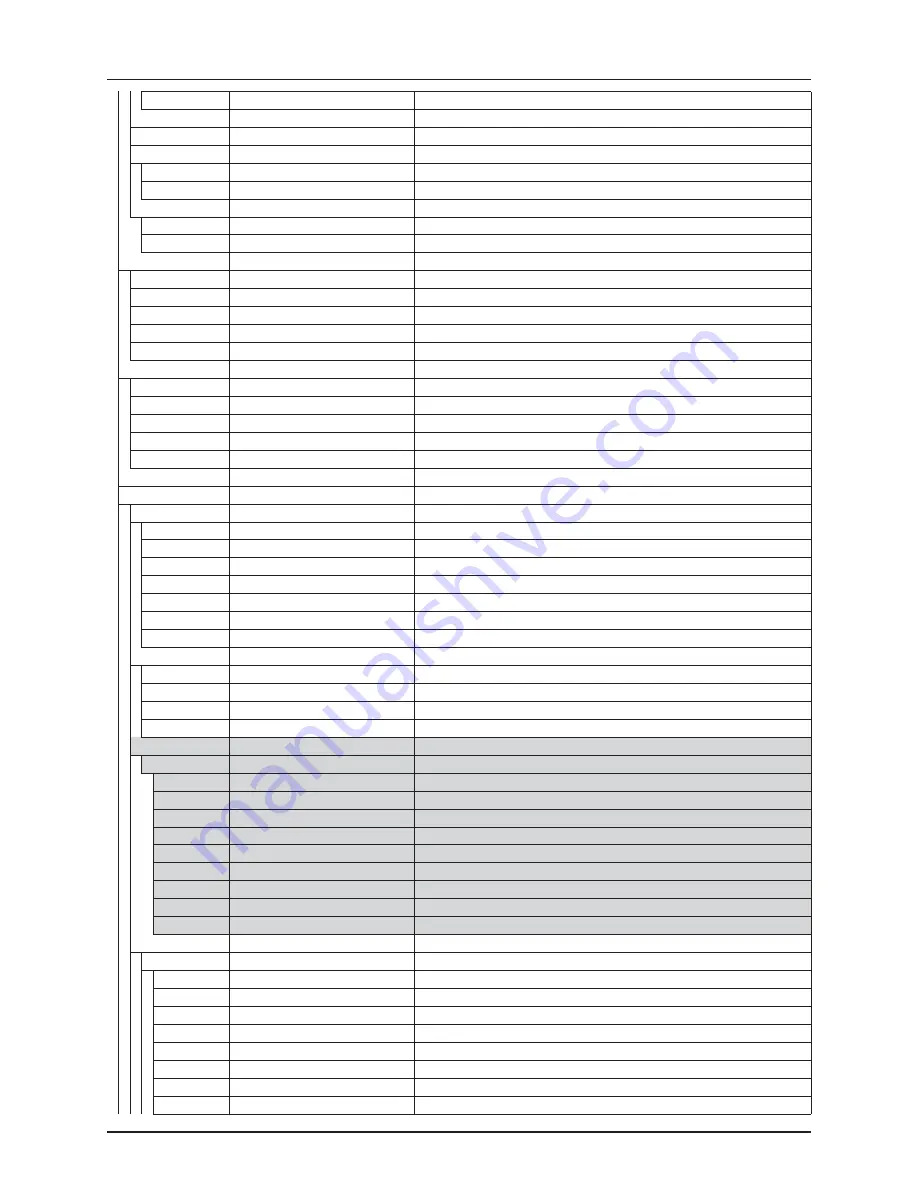

4. 1. 1.

2

Measure Distance

Measure started. Press Enter to stop and ESC to exit

4. 1. 2

Measure Area

If the implement width is Entered, area can also be measured

4. 1. 3

Setup working width

Key in the implement working width

4. 1. 4

Stop-watch

The clock can be used as a stop watch

4. 1. 4.

1

Stopwatch: Not active

Press C to clear. Press Enter to start, Esc to exit

4. 1. 4.

2

Stopwatch: Active

Press Enter to stop and edit. Press Esc to exit. Stopwatch will continue

4. 1. 5

Alarm clock

The clock can be set as an alarm clock

4. 1. 5.

1

Alarm clock: Not active

Key in time. Press C to clear. Press Enter to start. Press ESC to exit.

4. 1. 5.

2

Alarm clock: Active

Press Enter to stop and edit. Press Esc to exit. Alarm clock will continue

4. 2

Service interval: Hours until

Work hours remaining for each part until next service is recommended

4. 2. 1

10 hrs Check filters

4. 2. 2

50 hrs Grease boom

4. 2. 3

250 hrs Grease center

4. 2. 4

Misc. service

4. 2. 5

10 hrs Check nozzles

4. 3

Service interval reset

Reset timer counter when service has been carried out

4. 3. 1

Check filters reset

Press Enter to reset hour counter, ESC to leave unchanged

4. 3. 2

Grease boom reset

Press Enter to reset hour counter, ESC to leave unchanged

4. 3. 3

Grease track and center

Press Enter to reset hour counter, ESC to leave unchanged

4. 3. 4

Miscellaneous service

Press Enter to reset hour counter, ESC to leave unchanged

4. 3. 5

Check nozzles

Press Enter to reset hour counter, ESC to leave unchanged

4. 4

Reserved

R R

4. 5

Test of sensors

Test screens for buttons, sensor readings PrimeFlow status Valve friction

4. 5. 1

Flow Speed Optional sensors

Activate function to monitor sensor (e.g. drive forwards, start flow)

4. 5. 1.

1

Pressure

4. 5. 1.

2

Fan Speed

4. 5. 1.

3

Tank gauge

4. 5. 1.

4

Boom sensor

4. 5. 1.

5

Pressure regulation feedback

4. 5. 1.

6

Flow

4. 5. 1.

7

Speed

4. 5. 2

Active keys

Push key to see if a count is registered. If yes, the key or switch function is OK

4. 5. 2.

1

Keys on Terminal

4. 5. 2.

2

Keys on SetBox

4. 5. 2.

3

Keys on Grip

4. 5. 2.

4

Keys on FluidBox

4. 5. 3

PrimeFlow test

PrimeFlow test for nozzles and PrimeFlow computers on boom

4. 5. 3. 1 to 125

PrimeFlow computer status

Press Arrow DOWN to see next SMCU Arrow UP to see previous

4. 5.

3. 1. 1

Total SMCU’s

4. 5.

3. 1. 2

Total nozzles

4. 5.

3. 1. 3

This SMCU position

4. 5.

3. 1. 4

Nozzle order

4. 5.

3. 1. 5

Nozzle no short cab.

4. 5.

3. 1. 6

Nozzle medium cable

4. 5.

3. 1. 7

Nozzle no long cable

4. 5.

3. 1. 8

Count of data error

4. 5.

3. 1. 9

Count of power error

4. 5. 4

Input test

See computer readings of sensors Frequency, switch, analog inputs

4. 5. 4.

1

Frequency 1 Speed, Flow

Test of frequency input sensors: Speed, Flow, Tank gauge, Fan

4. 5.

4. 1. 1

Speed

4. 5.

4. 1. 2

Flow to sections

4. 5.

4. 1. 3

Flow from rinse tank

4. 5.

4. 1. 4

FlexCap pump RPM

4. 5.

4. 1. 5

Tank gauge

4. 5.

4. 1. 6

Wind Speed

4. 5.

4. 1. 7

Fan speed

4. 5.

4. 1. 8

PTO pump RPM

Summary of Contents for ISOBUS VT

Page 2: ......

Page 4: ......

Page 8: ...Table of contents TOC 4 ...

Page 10: ...1 Welcome 1 2 ...

Page 12: ...2 Safety notes 2 2 ...

Page 48: ...5 Menu 1 Daily settings 5 2 ...

Page 52: ...6 Menu 2 Setup 6 4 ...

Page 74: ...8 Menu 4 Toolbox 8 4 ...

Page 78: ...10 Maintenance 10 2 ...

Page 103: ......